Dry type seismic pressure gauge

A pressure gauge and earthquake-resistant technology, which is applied in the direction of elastic deformation meter fluid pressure measurement, etc., can solve the problems of poor earthquake resistance, low production cost, and high production efficiency, and achieve high production efficiency, low production cost, and reduced logistics costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

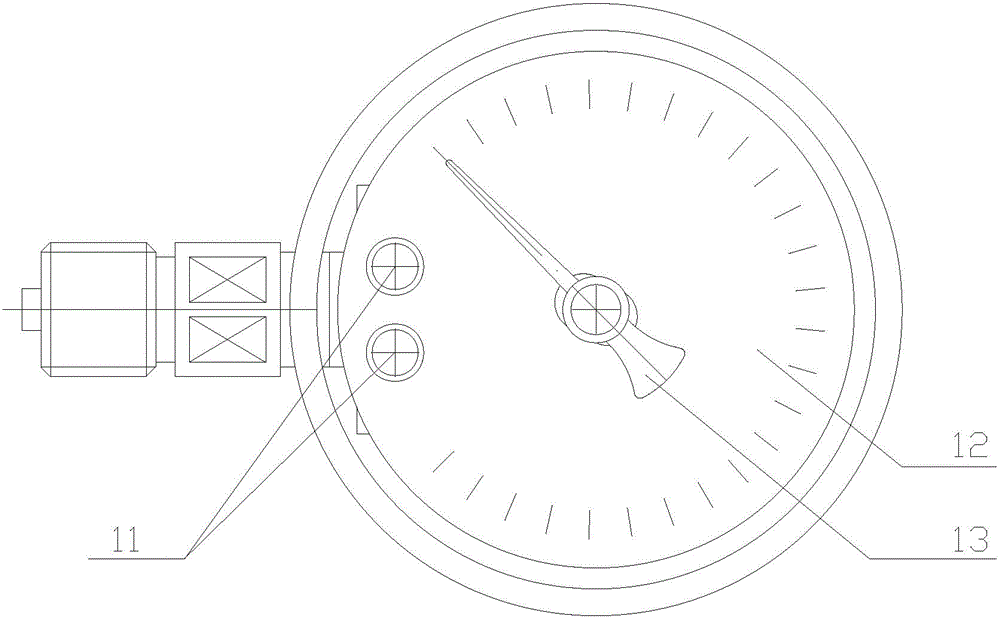

[0026] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

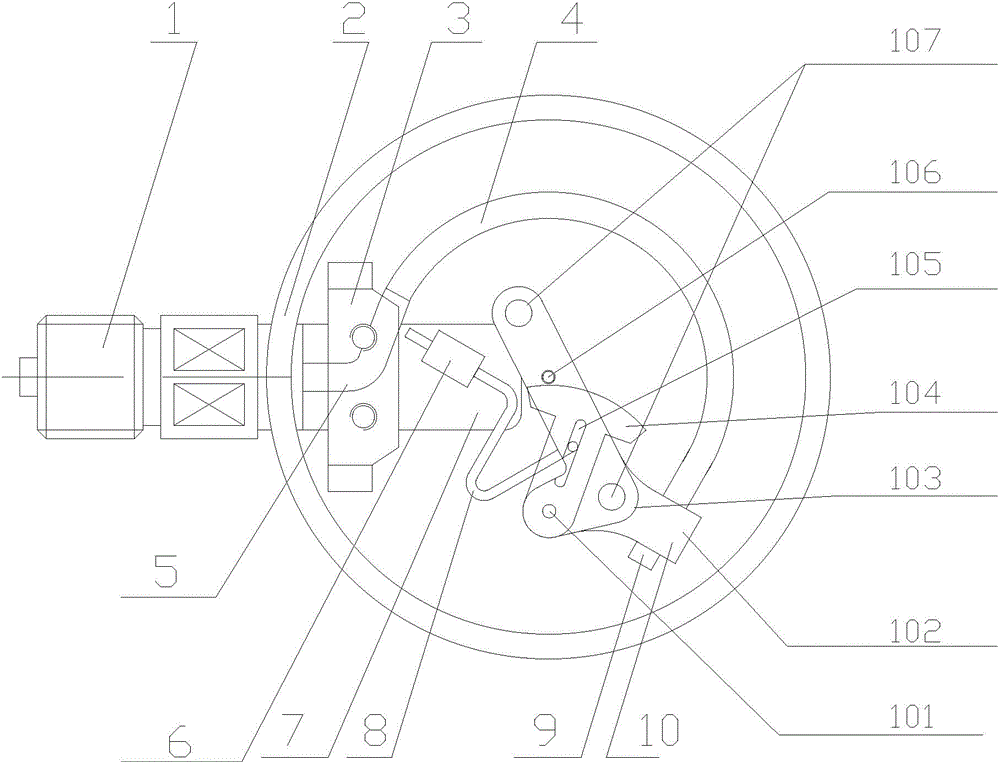

[0027] like figure 2 As shown, the measuring mechanism of this embodiment includes: a joint 1 , a watch case 2 , a bracket 3 , a Bourdon tube 4 , an air duct 5 , a fixed block 6 , a fixed piece 7 , a pulling rod 8 , a bulkhead 9 and a movement 10 .

[0028] Wherein the structure of movement 10 is as follows: movement 10 comprises rotating shaft 101, upper splint 102, lower splint 103, sector gear 104, central gear shaft 106 and pillar 107; Shaped cylinder, the middle part of the stepped cylinder has a larger diameter and a longer length, and the two ends have a smaller diameter and a shorter length.

[0029] The outline profile shape of lower clamping plate 103 approximates the upper part of the Y shape, and the outline profile shape of the upper clamping plate 102 approximates the Y fon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com