Resistor verifying system

A technology of resistance and resistance value, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve problems such as inaccurate control of sampling resistance, and achieve the effect of being suitable for promotion and reducing calibration errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

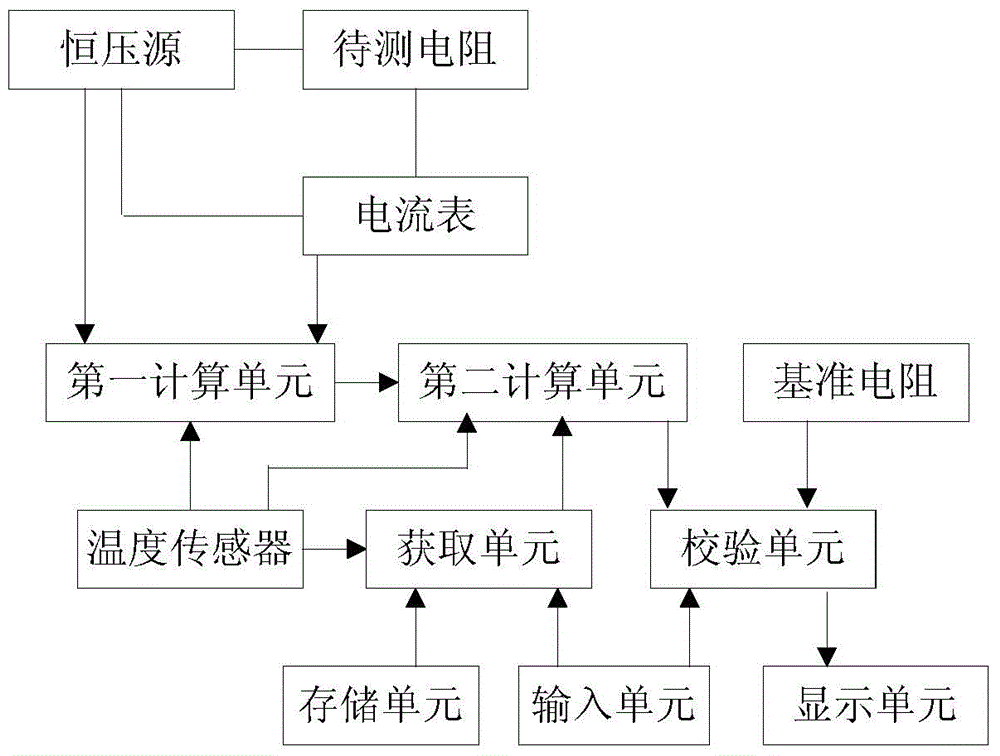

[0021] Such as figure 1 A resistance calibration system shown includes: a reference resistance whose resistance value is known at 20°C; a resistance to be measured; connected to both ends of the resistance to be measured and used to apply a constant voltage U across the resistance to be measured Constant voltage source; connected in series in the loop formed by the resistance to be measured and the constant voltage source, an ammeter for detecting the loop current I of the resistance to be measured; a temperature sensor for detecting the current ambient temperature t; connecting the constant voltage source, the ammeter and The temperature sensor is used to obtain the first calculation unit of the resistance value R of the resistance to be measured under the current ambient temperature t by using the formula R=U / I according to the constant voltage U applied to both ends of the resistance to be measured and the current I of the circuit; Connect the temperature sensor, be used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com