Self-suction type washing equipment for milk container and milk conveying equipment

A cleaning device and self-priming technology, which is applied to the cleaning method of using liquid, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of large pump failure, high pump cost, and polluted cleaning liquid, and achieve low cost, The effect of simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

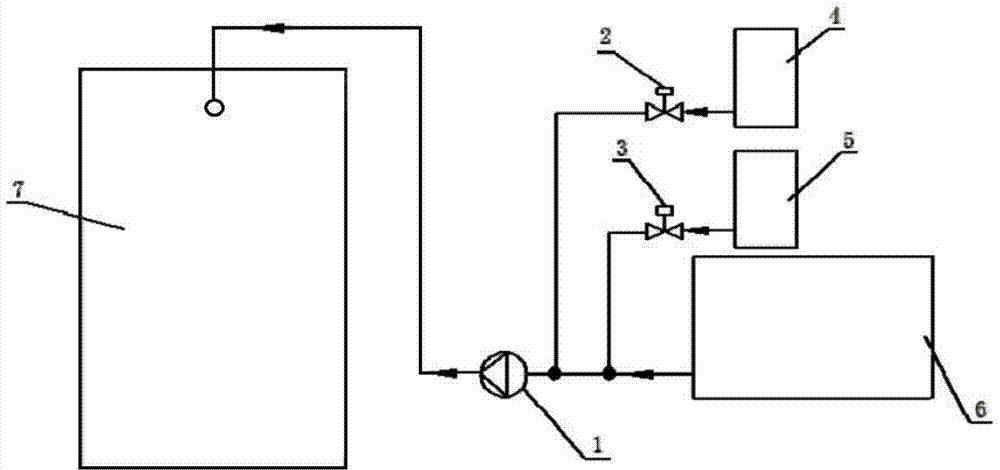

[0017] like figure 1 As shown, this embodiment is a self-priming cleaning device for milk tanks and milk delivery equipment, including a hot water pump 1, a hot water tank 6, an lye tank 4 and an acid tank 5, and the inlet port of the hot water pump 1 Be respectively connected with hot water tank 6, lye tank 4 and acid tank 5 by pipeline, be provided with an lye valve 2 on the pipeline of lye tank 4, be provided with an acid valve 3 on the pipeline of acid tank 5, heat The outlet end of the water pump 1 is connected with the milk tank and the milk delivery equipment 7 . The pipeline of the hot water tank 6 is directly connected to the inlet of the hot water pump 1, and the pipeline of the lye tank 4 and the pipeline of the acid tank 5 are respectively connected on the pipeline between the hot water tank 6 and the hot water pump 1. The pipeline between the hot water tank 6 and the hot water pump 1 can be an equal-diameter pipeline or a variable-diameter pipeline.

[0018] Whe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap