Laminated forming dies and preparation method thereof

A mold, complementary shape technology, applied in the field of manufacturing, can solve the problems of expensive and difficult to manufacture molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following description numerous specific details are provided to provide a thorough understanding of the concepts disclosed, some or all of which may not be practiced in practice. In other instances, details of known devices and / or processes are omitted to avoid unnecessarily obscuring the present disclosure. Although some concepts will be described in connection with particular examples, it will be understood that these examples are not intended to be limiting.

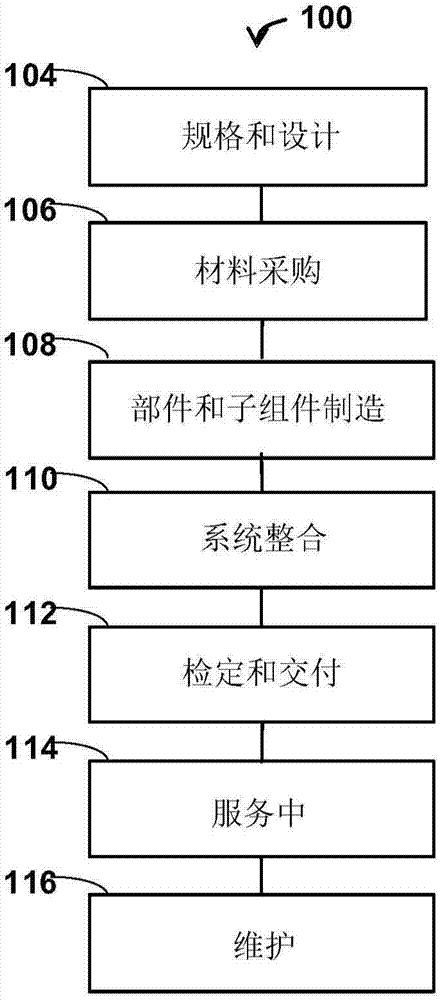

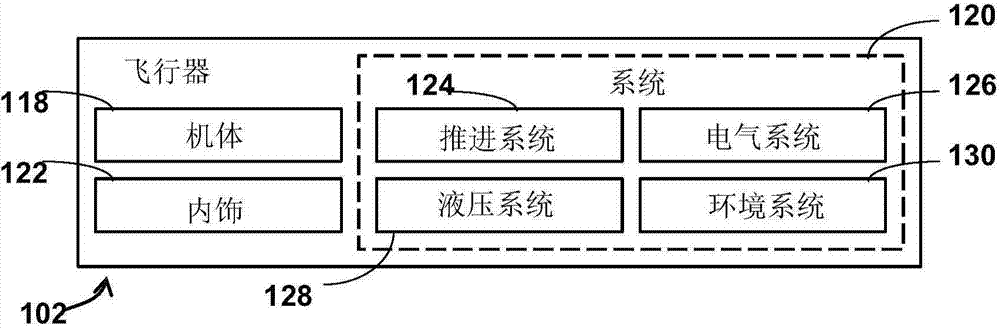

[0023] Referring now more specifically to the accompanying drawings, available at figure 1 Aircraft manufacturing and service method 100 shown and as figure 2 Examples of the present disclosure are described in the context of the aircraft 102 shown. During pre-production, exemplary method 100 may include specification and design 104 of aircraft 102 and material procurement 106 . During production, component and subassembly manufacturing 108 and system integration 110 of the aircraft 102 are performed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap