Automatic welding manifold integrated machine

A collector plate and all-in-one machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of unstable battery performance, poor spot welding consistency, and low work efficiency, so as to shorten the production line and prolong the service life , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

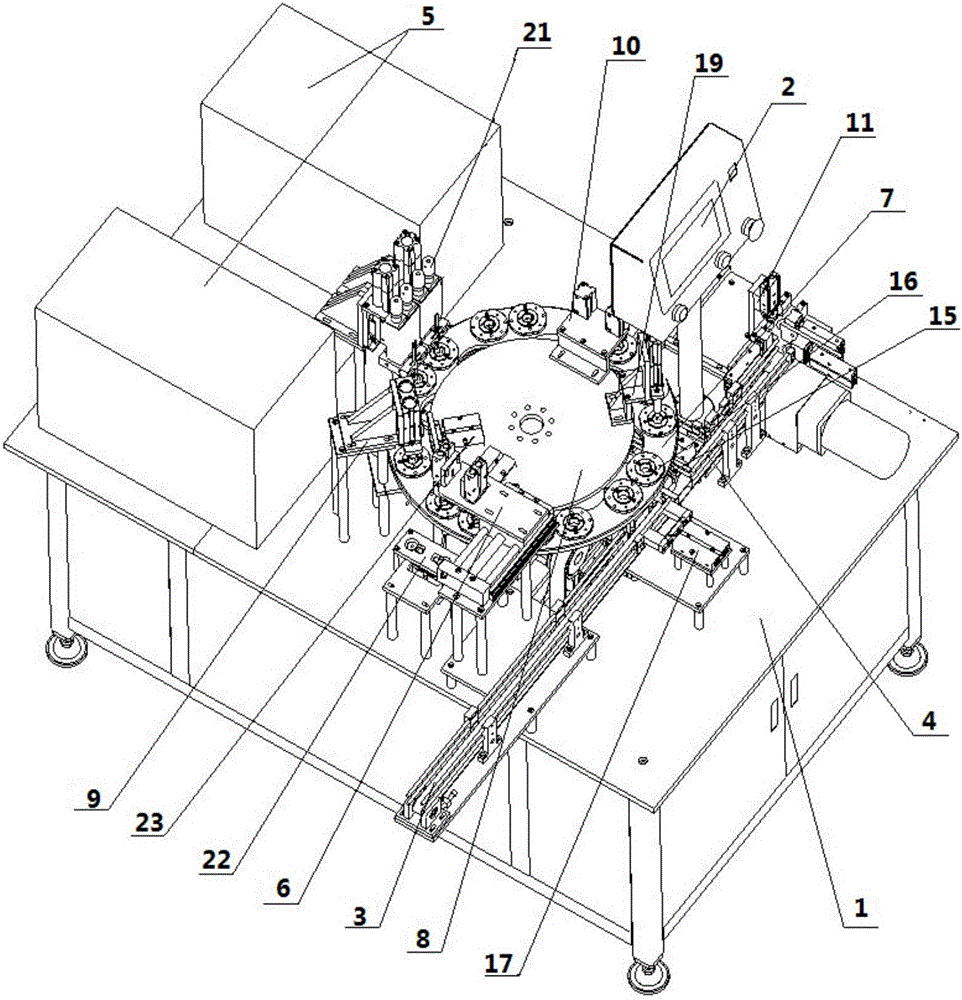

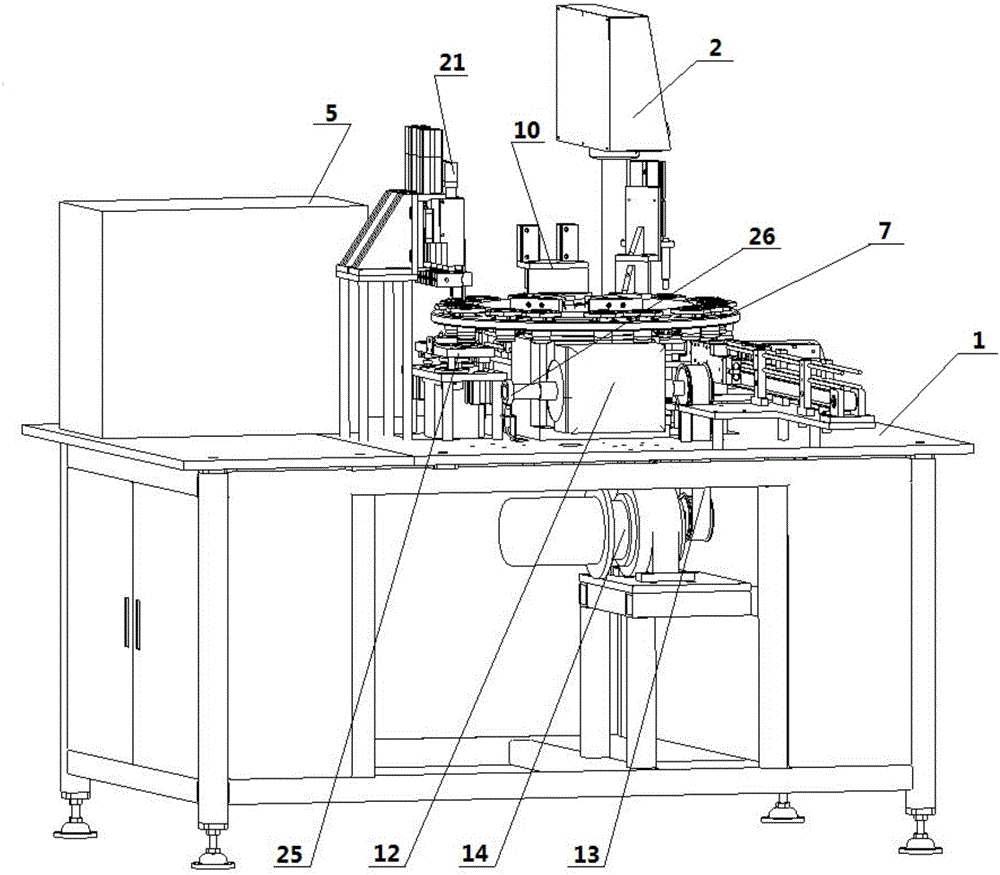

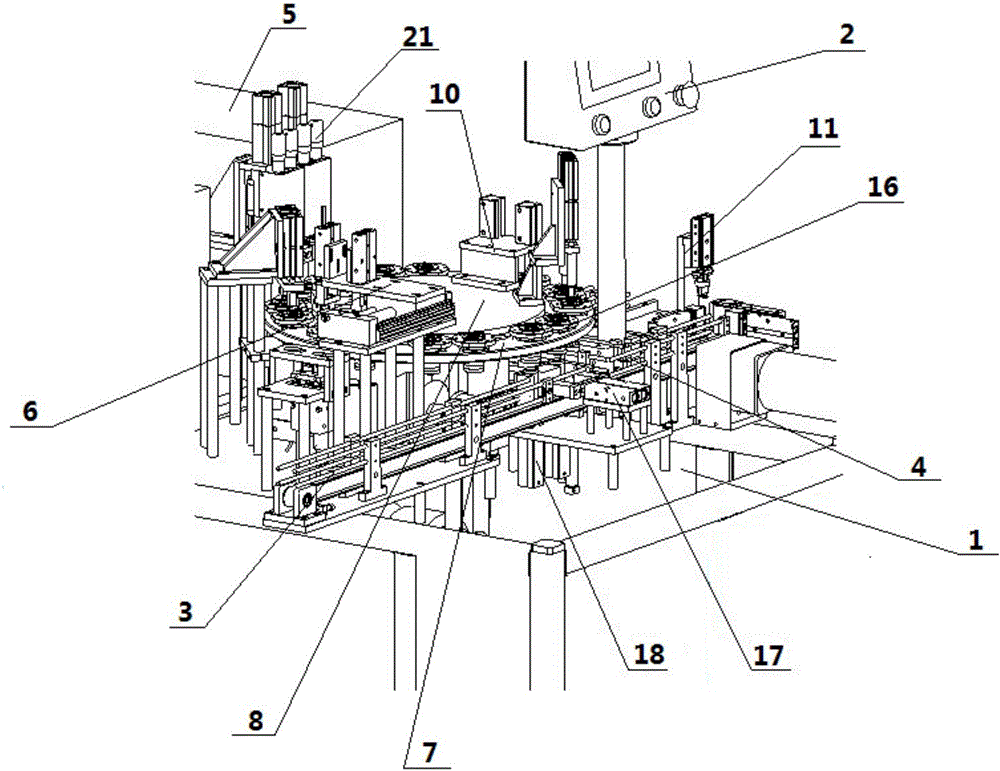

[0018] An automatic soldering manifold integrated machine, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes rack platform 1, operation control panel 2, feed chute 3, discharge chute 4, two spot welders 5, drain collector device 6, turntable 7, fixed disc 8, pressure collector device 9. Good product judging device 10, short circuit measuring device 11, operation control panel 2 is installed on the frame platform 1, the turntable 7 is circular, the fixed disk 8 is placed in the center of the turntable 7, and the fixed disk 8 and the turntable 7 are installed on the cam splitter 12, as figure 2 As shown, the cam divider 12 is provided with an inductor 26, the cam divider 12 is installed on the rack platform 1, the cam divider 12 is synchronized with the motor 14 installed under the rack platform 1 through the belt 13, and the periphery of the turntable 7 is arranged Several locating grooves 15 are arranged, and fixed mold 16 is housed in the locating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com