Novel tire having tire shoulder side ditches internally inlaid with T-shaped strip patterns

A technology of shoulder and pattern, which is applied to the field of T-stripe patterned tires embedded in the shoulder side groove, can solve the problems of not being able to discharge in time, lack of rubber on the shoulder, and the exhaust line is long, etc., and saves money. Human and material resources, improve the first-time appearance pass rate, and increase the decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

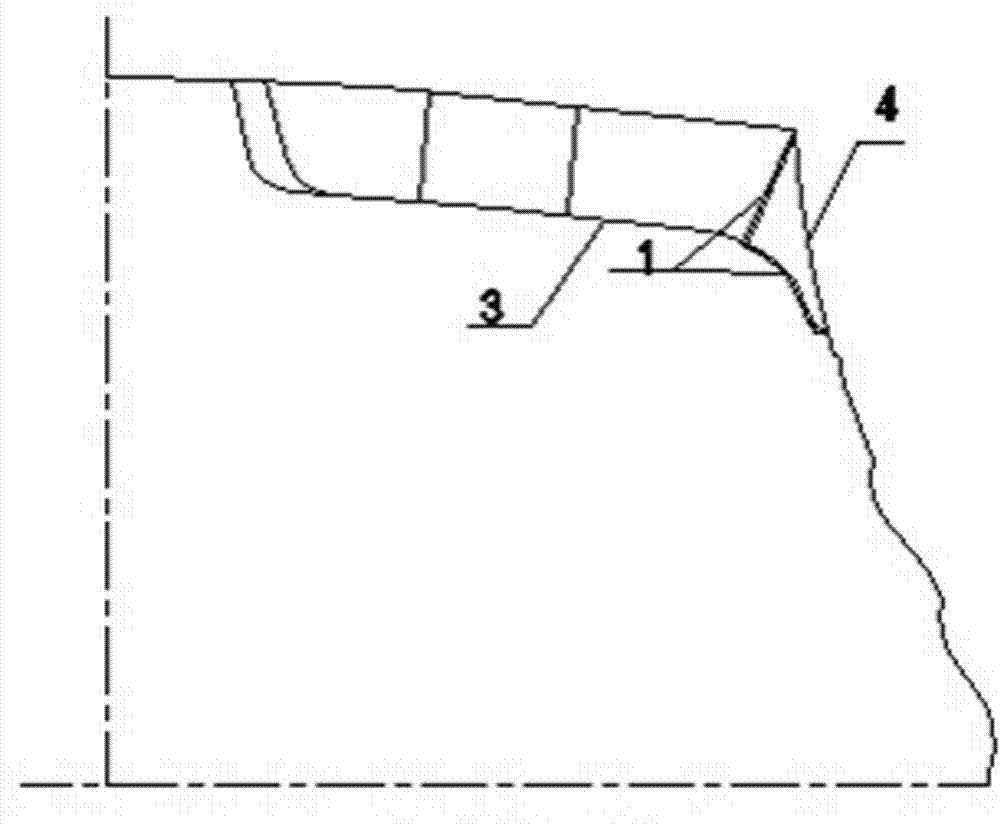

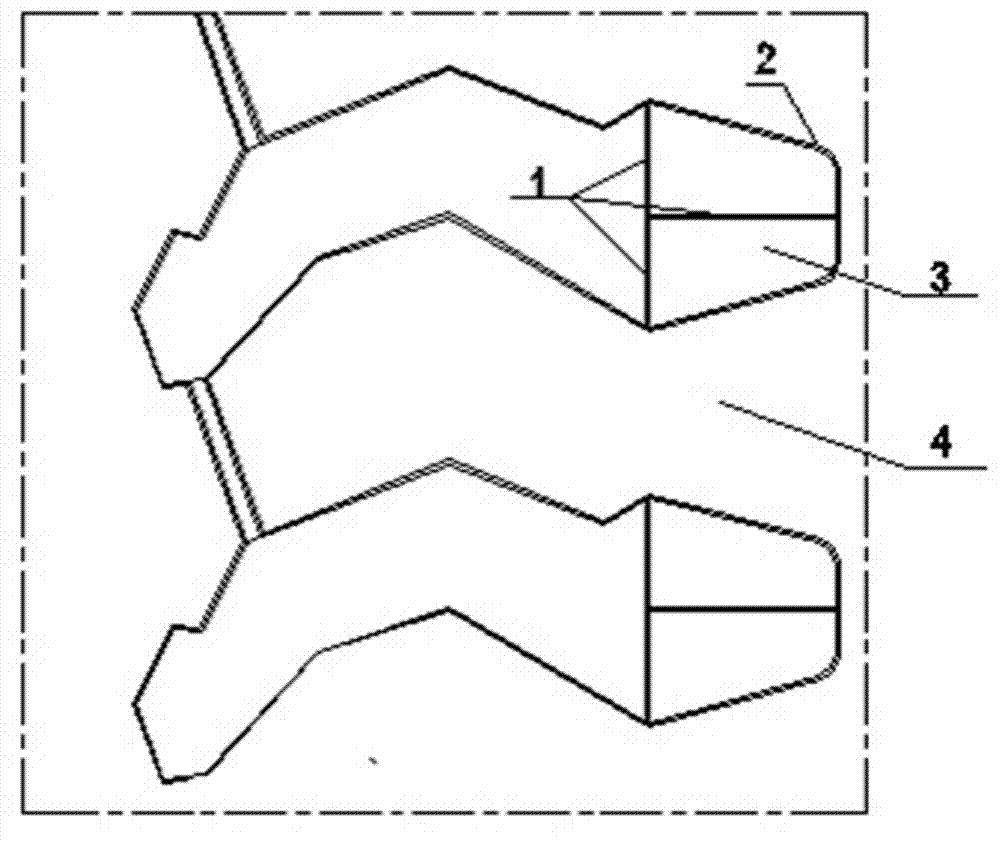

[0012] As shown in the figure: a new type of tire with T-shaped stripe pattern embedded in the shoulder side groove, there is a T-shaped stripe 1 pattern on the shoulder groove 3, and the end of the T-shaped stripe 1 pattern extends to the pattern block 4 around the tire and connected with the peripheral boss bar 2 of the pattern block; the cross-sectional shape of the T-shaped bar 1 and the peripheral boss bar 2 is a U-shaped structure.

[0013] The series of patterns fed back by the manufacturing department produce serious defects of lack of rubber in the shoulders, and there are sunken scars or cracks lacking material in the circumferential direction on the shoulders. According to statistics, the rate of lack of rubber in shoulder rubber tires reaches 7.3%. According to the invention A new type of tire with T-shaped stripe pattern embedded in the shoulder side groove. During vulcanization, because the shoulder groove 3 pattern is deeper and the cross section is wider, the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com