Collapsible bracket

A technology for collars and collars, applied in the field of collar holders, can solve problems such as out-of-shape, buckling deformation, and crooked resin sheet 4, and achieve the effect of strengthening linear stretchability and enhancing decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

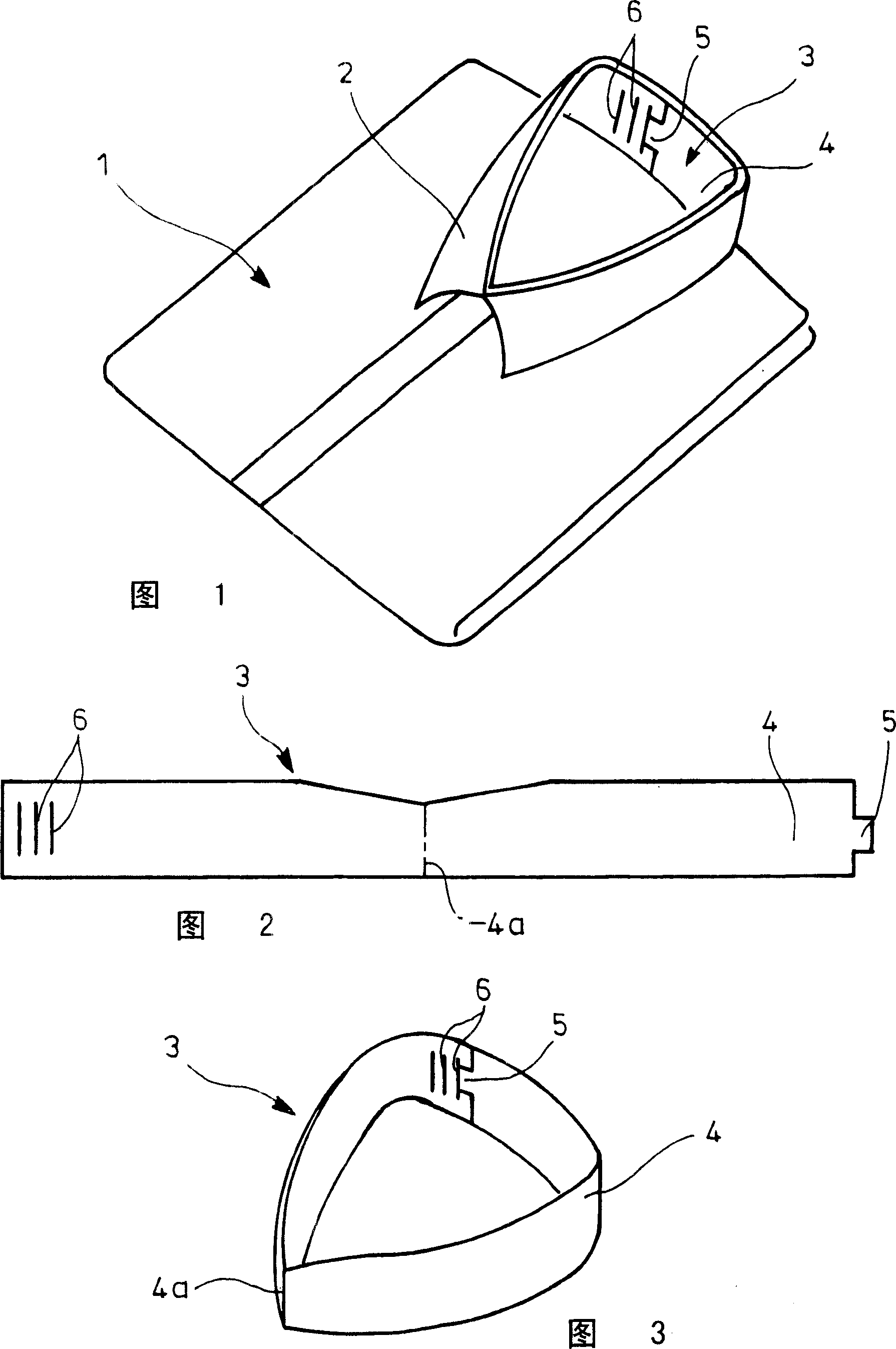

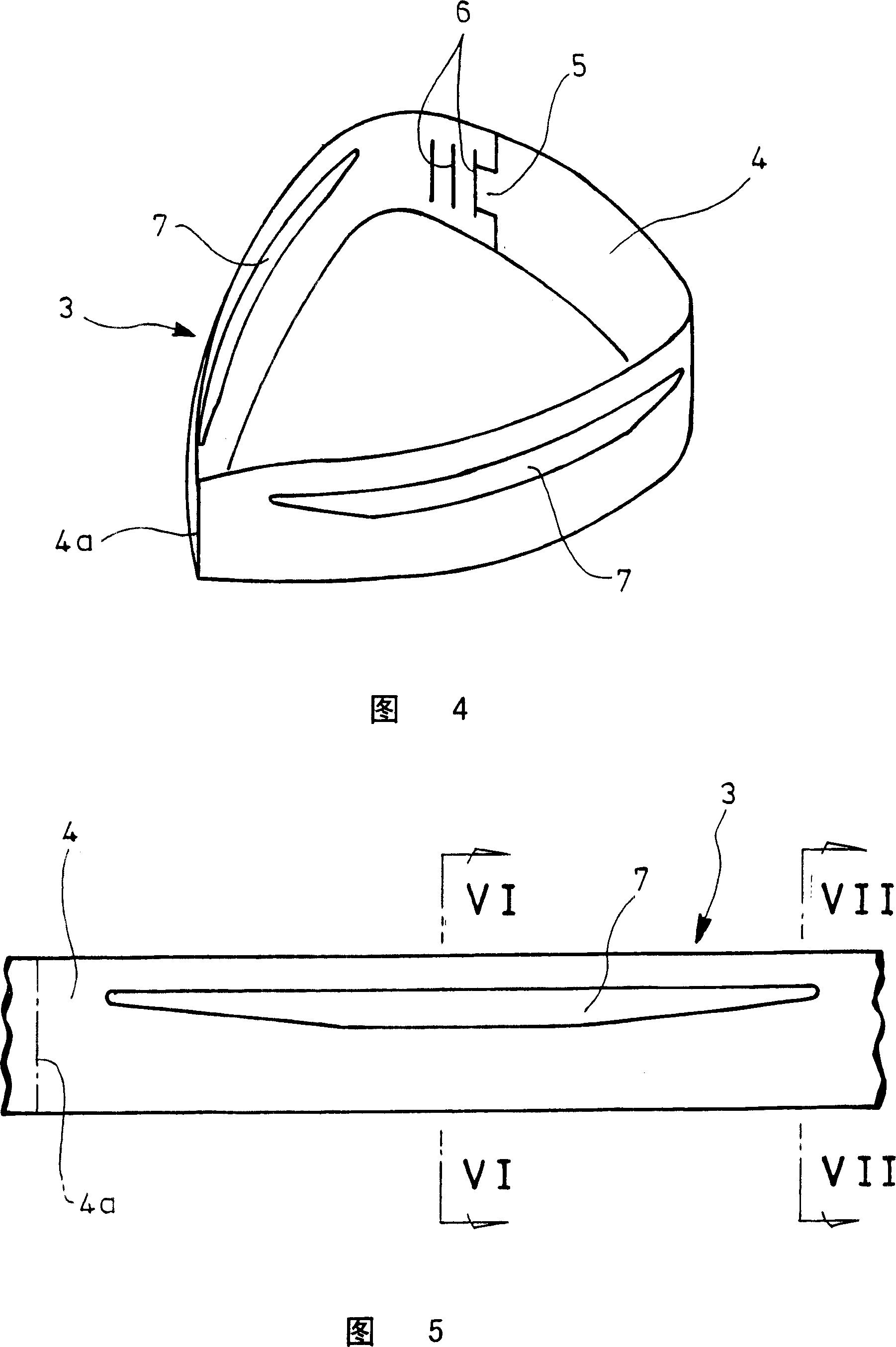

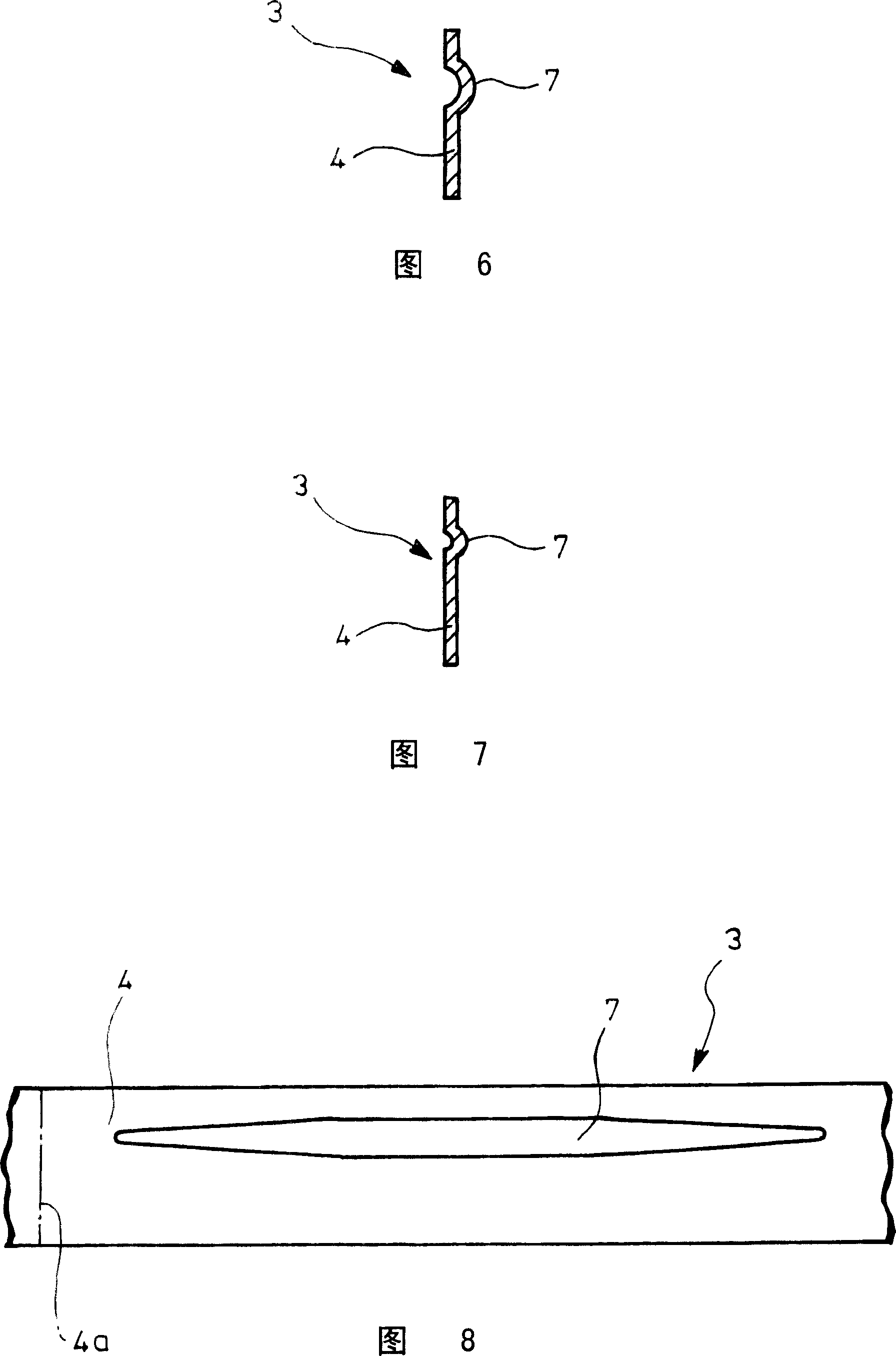

[0021] Fig. 4~Fig. 7 is the figure that represents an embodiment of the present invention, and the collar holder 3 of present embodiment is roughly the same as the collar holder 3 of aforementioned Fig. 2 and Fig. sheet) composed of a resin sheet 4 that is assembled into a ring shape by inserting a convex fin 5 formed at one end in the longitudinal direction into any one of a plurality of slits 6 formed at the other end side, Reinforcing grooves 7 extending in the longitudinal direction of the resin sheet 4 and gradually decreasing in width near both ends are formed on the left and right positions of the resin sheet 4 across the longitudinal central portion 4a.

[0022] In particular, in the illustrated example, the reinforcing grooves 7 are formed in a boat shape (see FIG. 5 in particular), and one pair is formed on the left and right at the same height on the upper end side of the resin sheet 4 .

[0023] Then, if the collar support 3 is constituted in this way, when the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com