Porous ceramic decorative plate with maishi paint and production method of porous ceramic decorative plate

A technology of porous ceramic plates and porous ceramics, which is applied in the field of architectural decoration, can solve the problems of heavy workload, heavy quality, and non-processing of porous ceramics, and achieve the effect of improving decoration and enhancing durability

Active Publication Date: 2018-09-21

GUANGDONG KITO CERAMICS GROUP CO LTD +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] For example, "A Porous Ceramic" proposed in the Chinese patent CN201710162646.3A, although the porous ceramic plate proposed in this scheme improves the flexural strength of the porous ceramic, it does not treat the surface of the porous ceramic, and there are still the following Problems: 1. Porous ceramics are still not decorative; 2. It is not conducive to directly setting coatings on the surface of porous ceramics

[0004] For example, the panel exterior wall thermal insulation decorative panel proposed in Chinese patent CN201711093426.6 provides a way to install the decorat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

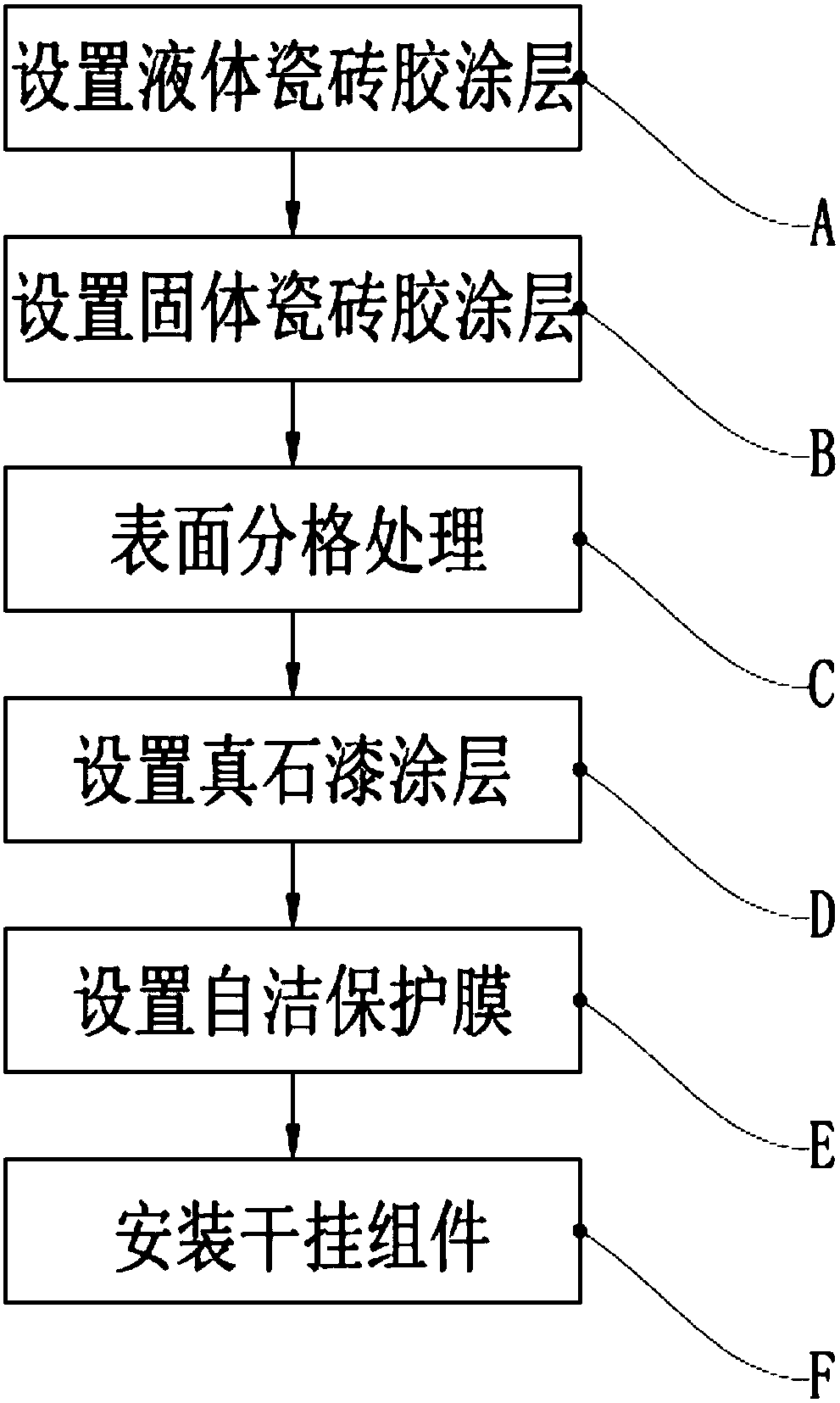

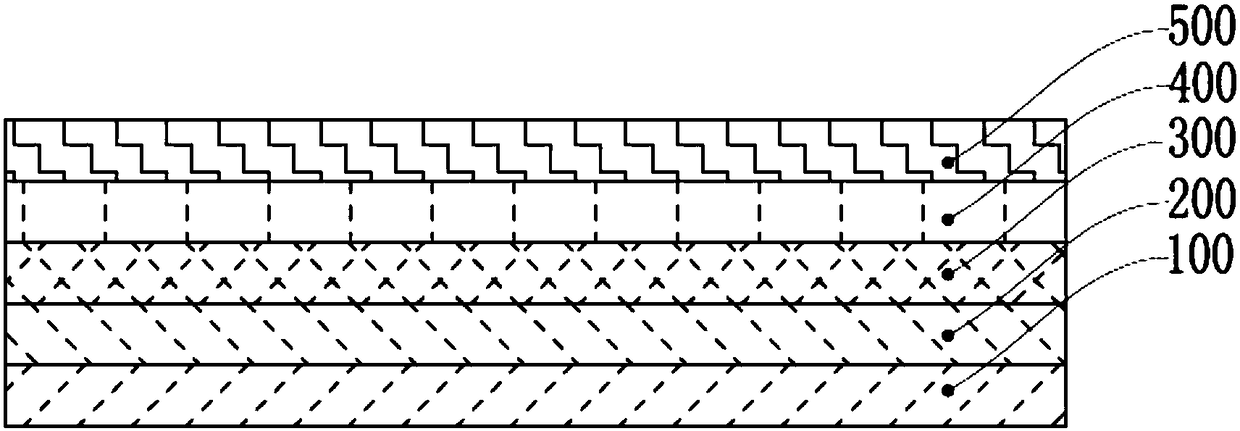

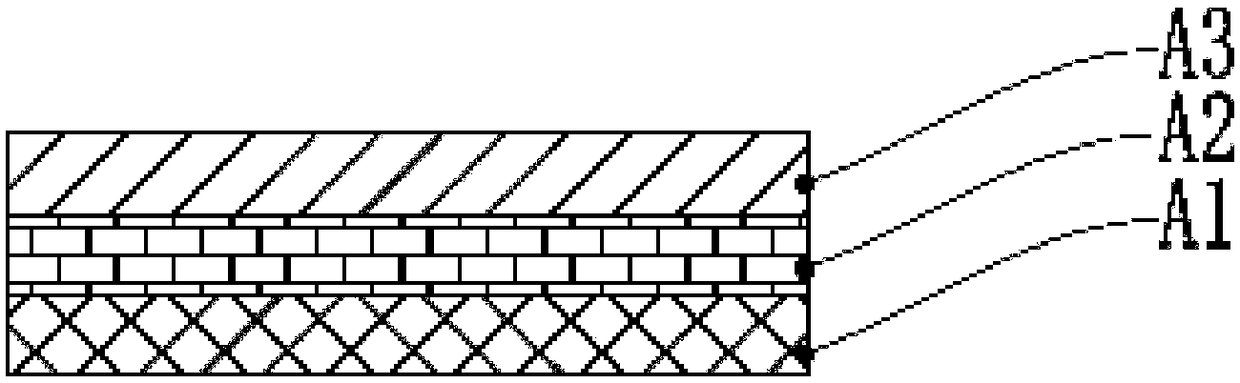

The invention discloses a production method of a porous ceramic decorative plate with maishi paint. The production method comprises the following steps that A, a liquid tile glue coating is arranged,specifically, the liquid tile glue coating is formed on the surface of a porous ceramic plate by liquid tile glue and the liquid tile glue infiltrates into the porous ceramic plate; B, a solid tile glue coating is arranged, specifically, the solid tile glue coating is sprayed after the liquid tile glue coating is formed; C, surface latticing treatment is carried out, specifically, after the solidtile glue coating is formed, a sponge adhesive tape is pasted on the solid tile glue coating so that a pattern is formed by the sponge adhesive tape; and D, a maishi paint coating is arranged, specifically, the solid tile glue coating is coated with the maishi paint so that the maishi paint coating can be formed, then the sponge adhesive tape is torn down, and the parts where the adhesive tape istorn down are provided with no maishi paint coating, so that an outline of the pattern is formed. With the adoption of the production method of the porous ceramic decorative plate with the maishi paint, the porous ceramic decorative plate is obtained and is integrated with the maishi paint coating, so that the porous ceramic decorative plate has the appearance of stone and is capable of protectinga porous ceramic substrate.

Description

technical field [0001] The invention relates to the technical field of architectural decoration, in particular to a porous ceramic decorative plate with self-cleaning function and a manufacturing method thereof. Background technique [0002] The real stone paint series is made of high-quality natural colored sand as aggregate, together with high-quality emulsion and high-quality additives. It is a high-grade anti-stone texture coating for exterior walls and an ideal substitute for natural stone. The buildings decorated with natural stone paint have natural and real natural color, which gives people a better visual experience, and is suitable for indoor and outdoor decoration of all kinds of buildings. Especially for decoration on curved buildings, it can receive vivid and return to nature effects, and at the same time has excellent anti-fouling and excellent weather resistance, providing excellent protection for buildings. [0003] For example, "A Porous Ceramic" proposed i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05D5/06B05D7/00C04B28/04C09J131/04C09J161/06C09J163/00C09J11/08C09J11/04

CPCC09J11/04C09J11/08C09J131/04C04B28/04B05D5/066B05D7/58B05D2502/00B05D2504/00B05D2518/12B05D2518/00B05D2301/00B05D2320/00C04B14/06C04B14/28C04B2103/0057C04B24/281C04B24/42C04B24/383C04B24/38B05D2420/01B05D2420/02C08L63/00C08L61/06C08K13/02C08K3/36

Inventor 张国涛黄惠宁张王林江期鸣黄辛辰

Owner GUANGDONG KITO CERAMICS GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com