High-performance three-dimensional drum cover

A high-performance, three-dimensional technology, used in textiles and papermaking, non-woven fabrics, needle punching machines, etc., can solve the problem that the three-dimensional effect and clarity of the pattern cannot meet the requirements of consumers, and ensure continuity and regularity. The effect of reducing displacement variation, improving stereoscopic effect and sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

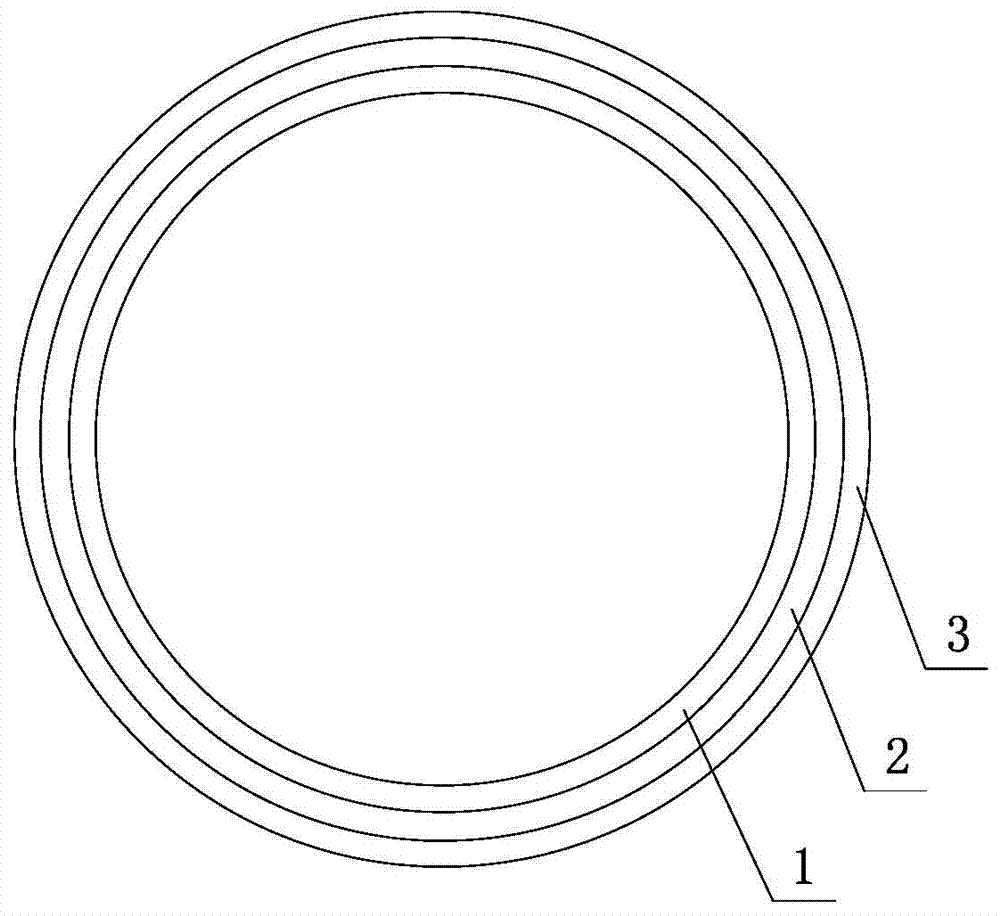

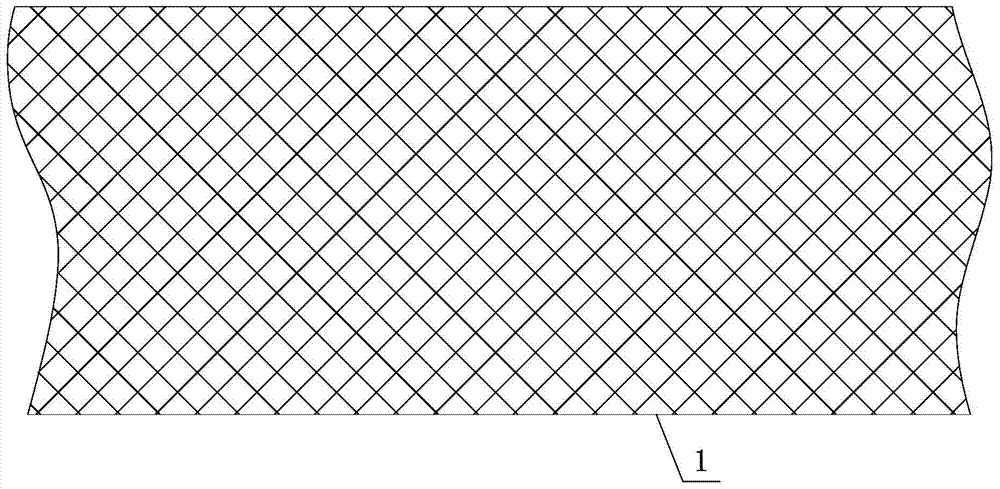

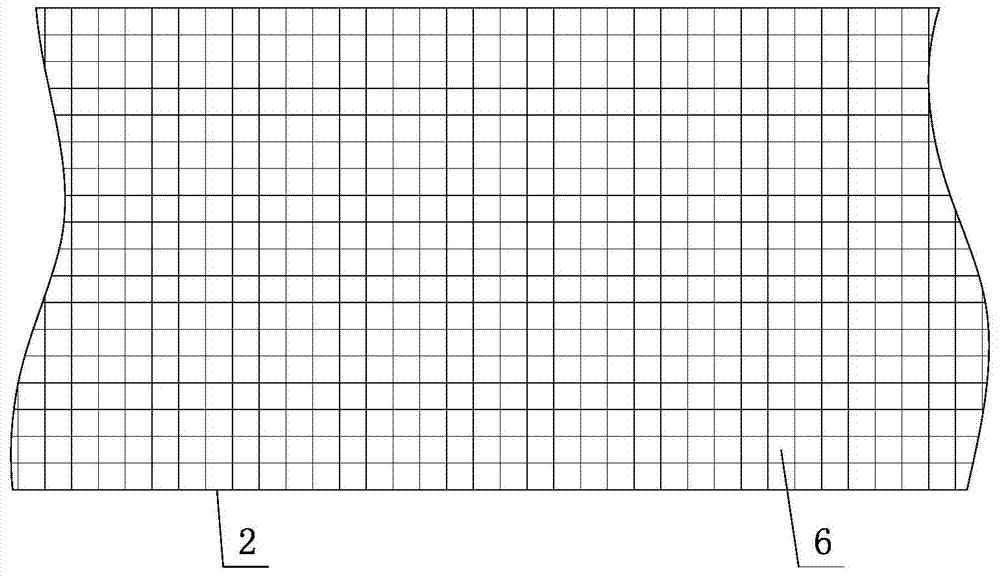

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a high-performance three-dimensional drum cover of the present invention includes a diamond-shaped stainless steel support cover 1, a stainless steel wire mesh 2, and a stainless steel nickel-plated microporous treatment mesh 3 fixedly arranged in sequence from the inside to the outside. Among them, several micropores 4 and several patterned hole units 5 are evenly opened on the stainless steel nickel-plated microporous treatment net 3 .

[0014] In order to further improve the structural stability, the number of meshes 6 on the stainless steel wire mesh 2 of the present invention is 35 meshes.

[0015] The invention is a high-performance three-dimensional drum cover with high structural stability. During the process of producing spunlace non-woven fabrics, the displacement changes between the diamond-shaped stainless steel support cover 1, the stainless steel wire mesh 2, and the stainless steel nicke...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap