Butt joint type pneumatic pipe joint integration module

A technology of integrated modules and pneumatic tubes, applied in the direction of pipes/pipe joints/fittings, pipes, pipe components, etc., can solve the problems of inconvenient testing and maintenance, complex pneumatic pipelines, etc., to improve service life and solve complex pneumatic pipelines , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

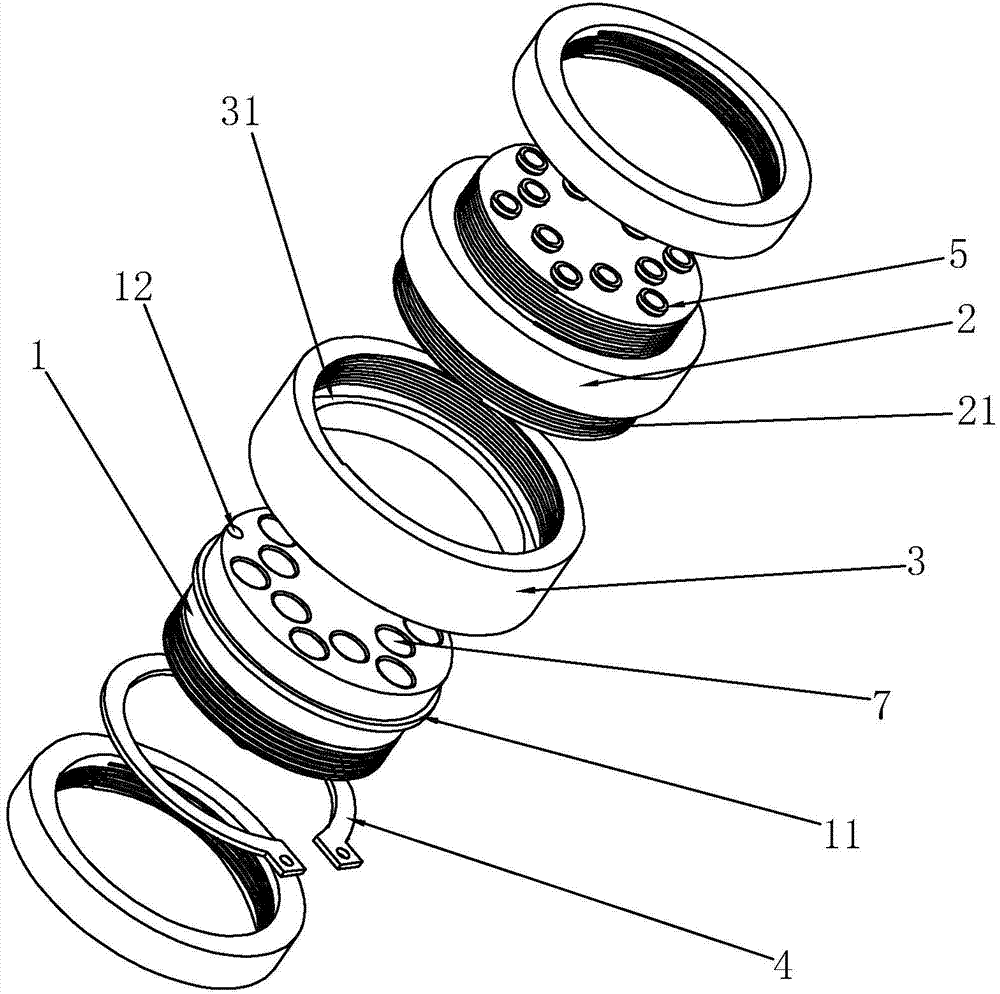

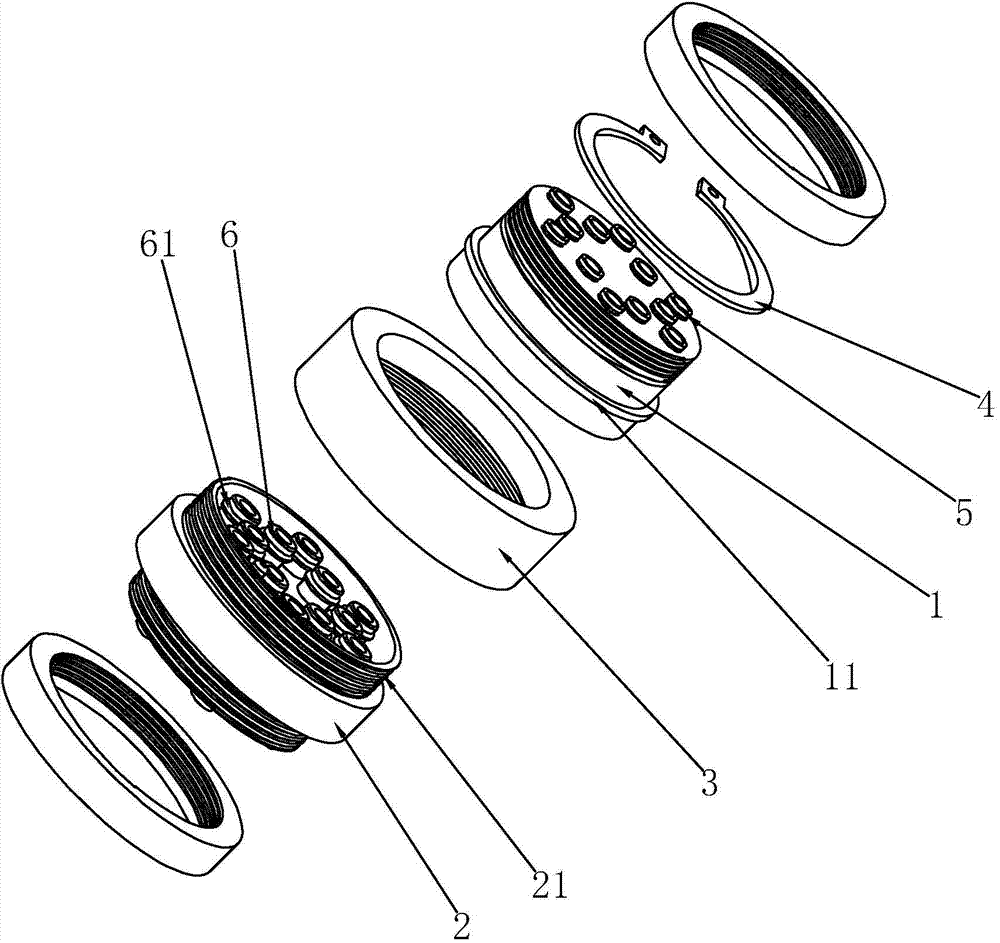

[0034] refer to Figure 1 to Figure 11 The embodiment of the butt joint pneumatic pipe joint integrated module of the present invention will be further described.

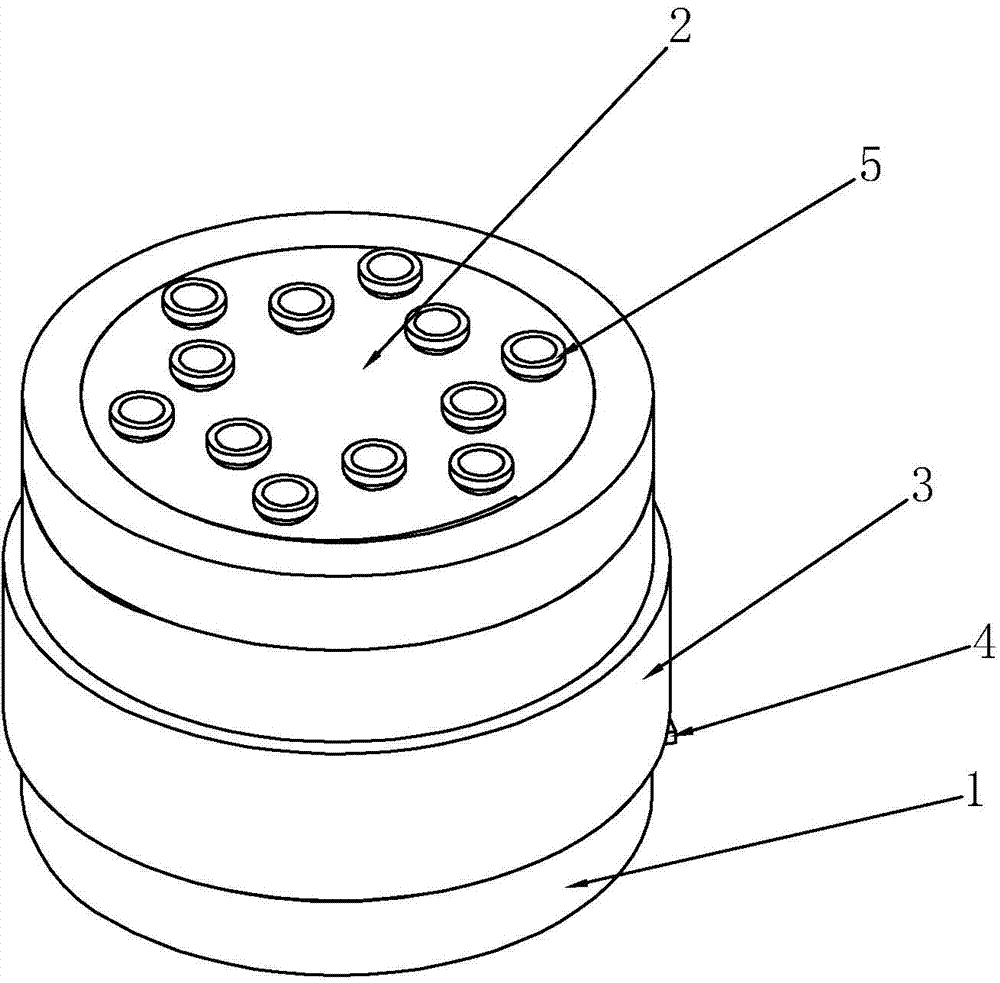

[0035] The integrated module of the docking type pneumatic pipe joint of the present invention, such as figure 1 As shown, it includes a left installation disk 1 and a right installation disk 2. The left installation disk 1 and the right installation disk 2 are provided with a number of through holes 7, and the positions of the through holes 7 of the two installation disks are all corresponding to each other. The left installation disk 1 and the right installation disk 2 are docked, and the through holes 7 corresponding to the left installation disk 1 and the right installation disk 2 can be detachably sealed and connected, and any installation disk is opposite to the other installation disk. Pneumatic pipe joints 5 are installed at the openings on the sides of the through holes 7 . The pneumatic pipe joint 5 ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com