Wallboard type novel underground continuous wall and construction method thereof

A technology of underground diaphragm wall and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., which can solve the problems of difficult and intractable construction quality control, and avoid the risk and cost of joint pipe disconnection or buried pipe Low and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

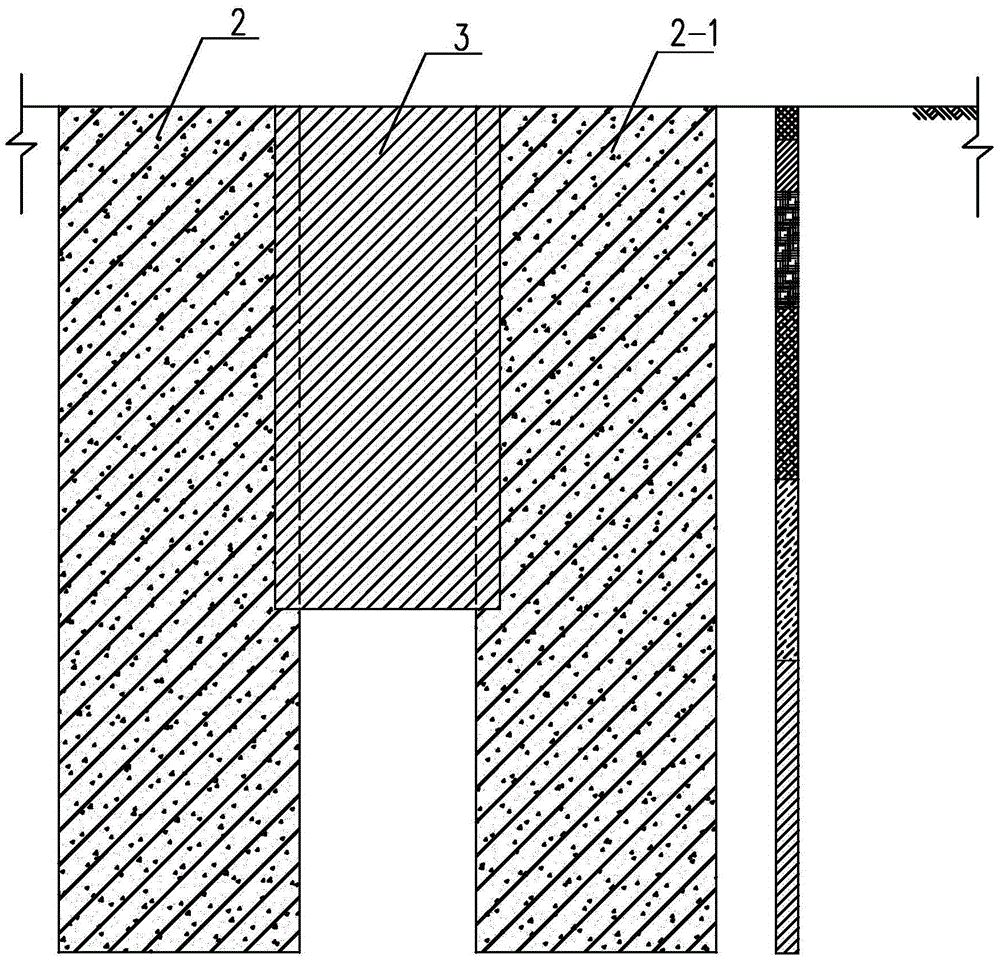

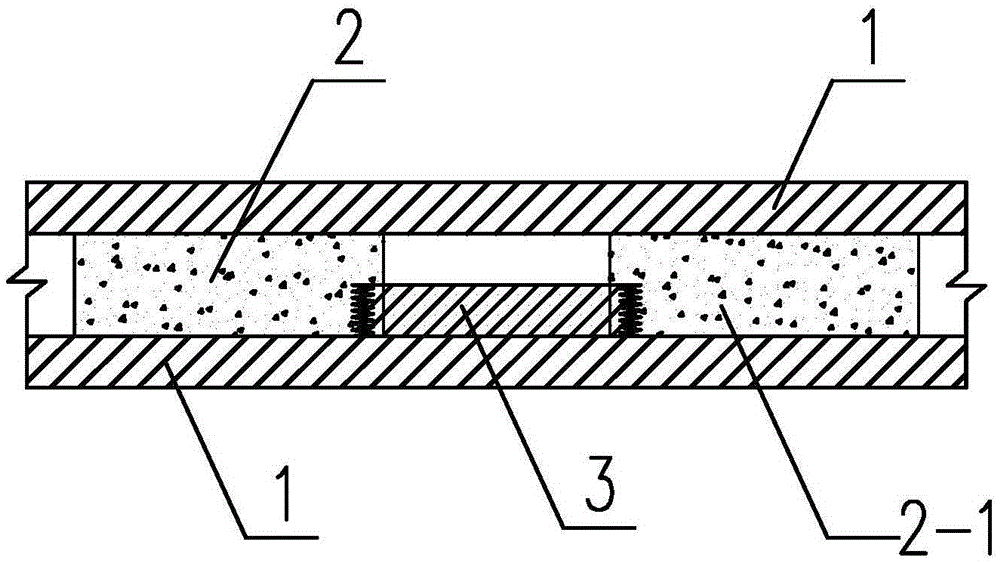

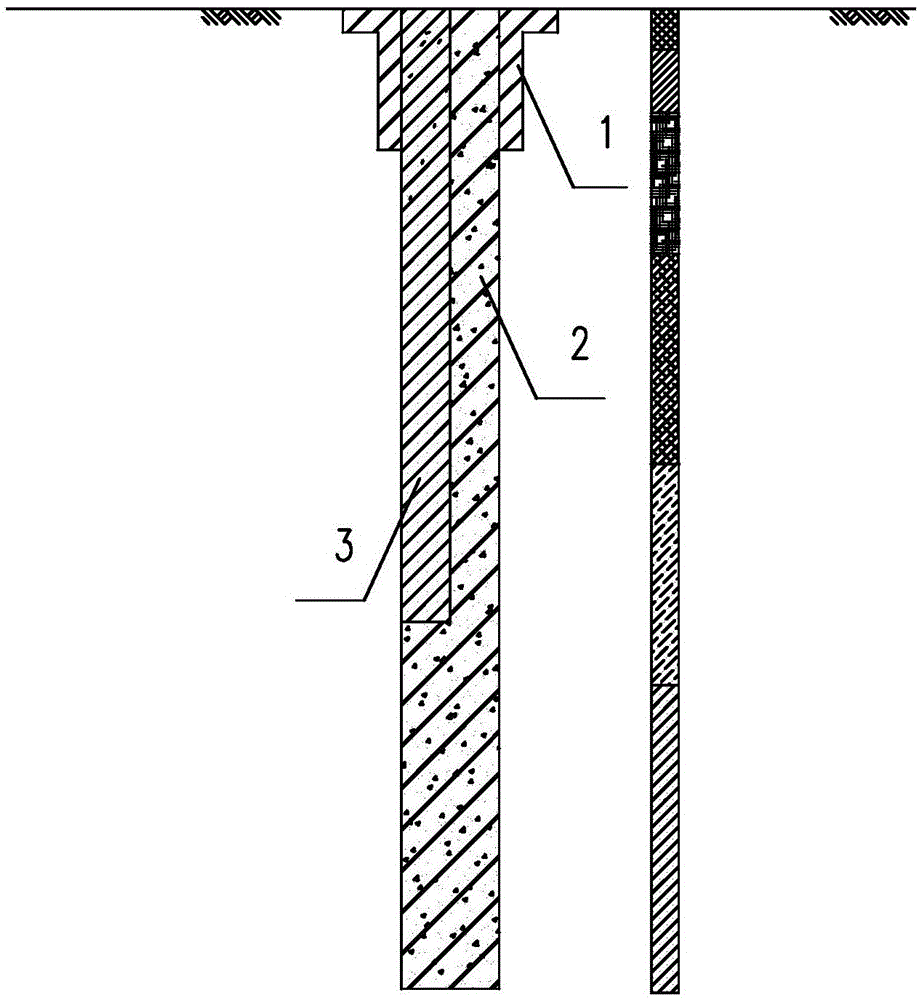

Embodiment 1

[0030] Example 1: Specifically for a certain foundation pit, the main structure is a 46-story frame-tube structure, with a three-story basement, the excavation depth of the foundation pit is 17.51m, and the side walls of the foundation pit are miscellaneous fills from top to bottom. Sandy silt, silty clay, silty clay, sandy silt interbedded with silt and fine silt, groundwater is mainly stagnant water and confined water. The project adopts a new type of wall plate type underground diaphragm wall as the enclosure structure of the foundation pit. During the construction stage of the foundation pit, the underground diaphragm wall is used as both a soil retaining structure and a water-stop curtain. The thickness of the main wall of the diaphragm wall is 1.0m, and the thickness of the milling plate is 0.6m. After the construction of the underground diaphragm wall is completed, the guide wall near the inner side of the foundation pit will be removed, and three horizontal reinforced c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com