Method for detecting fabric defects by using computer

A computer and defect technology, used in the textile industry, can solve the problems of low defect detection accuracy, difficulty in solving image interference, and difficulty in applying complex background color fabric detection, etc., to achieve the effect of high defect detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A high-brightness projector is used to irradiate coded light information, which may be moiré fringes, onto the surface of the fabric to be tested.

[0033] The coded light information is moved three times, and the coded light information is irradiated onto the surface of the fabric to be tested three times from three different angles to obtain three coded images reflected by the surface of the fabric to be tested.

[0034] Acquisition of coded images reflected on the surface of the fabric to be tested is achieved by an image acquisition system. The image acquisition system includes a CCD camera and a computer connected with the camera. The CCD camera collects the image of the surface of the fabric to be tested from another angle, and then transmits it to the computer for data calculation.

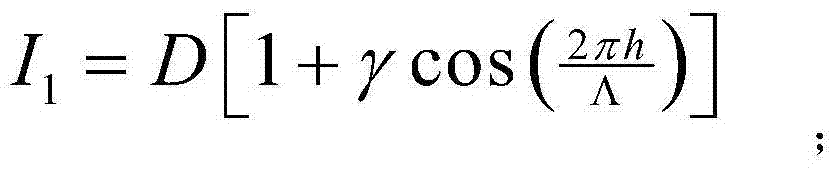

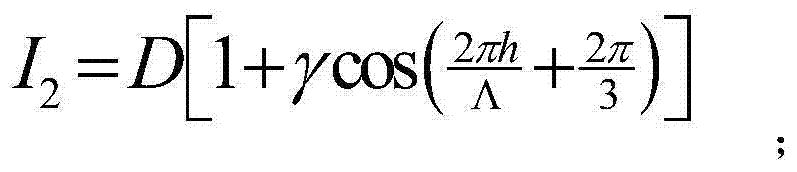

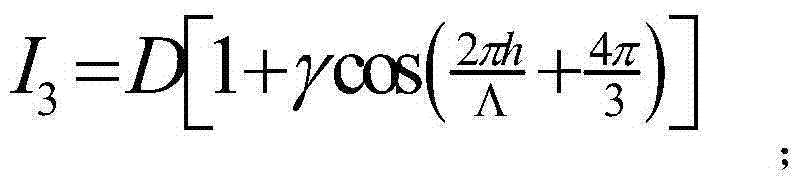

[0035] Calculate the space coordinates (x, y, h) of any point (x, y) on the space image of the fabric to be tested according to the preset program. The pre-set programs are calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com