Probe measuring system

A probe and point measurement technology, which is applied in the field of probe point measurement system, can solve problems such as poor contact, difficulty in finding abnormal conditions of incoming wafers, and damaged probes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

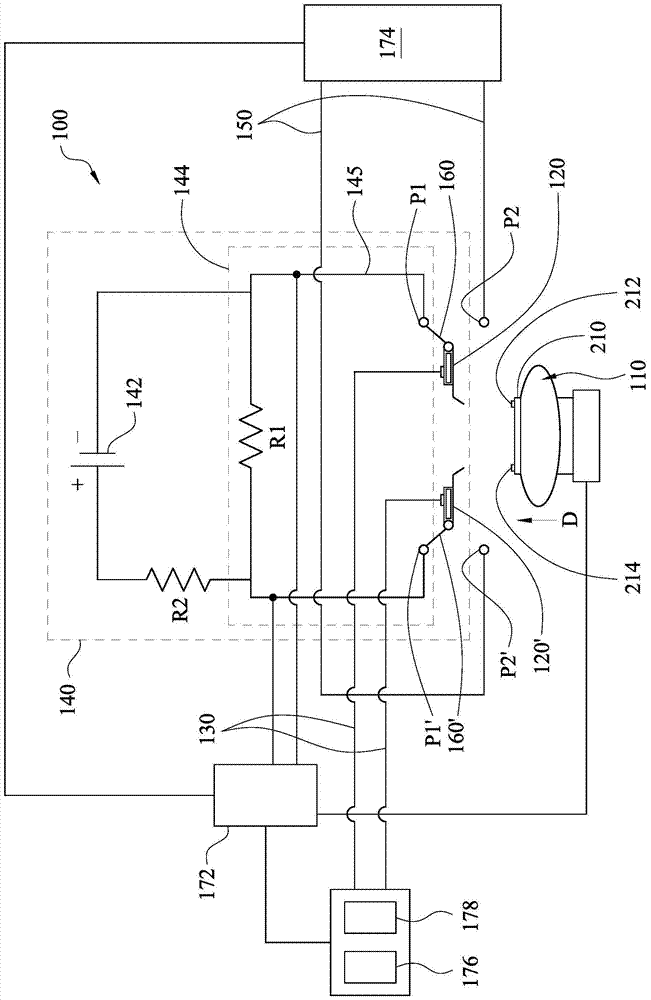

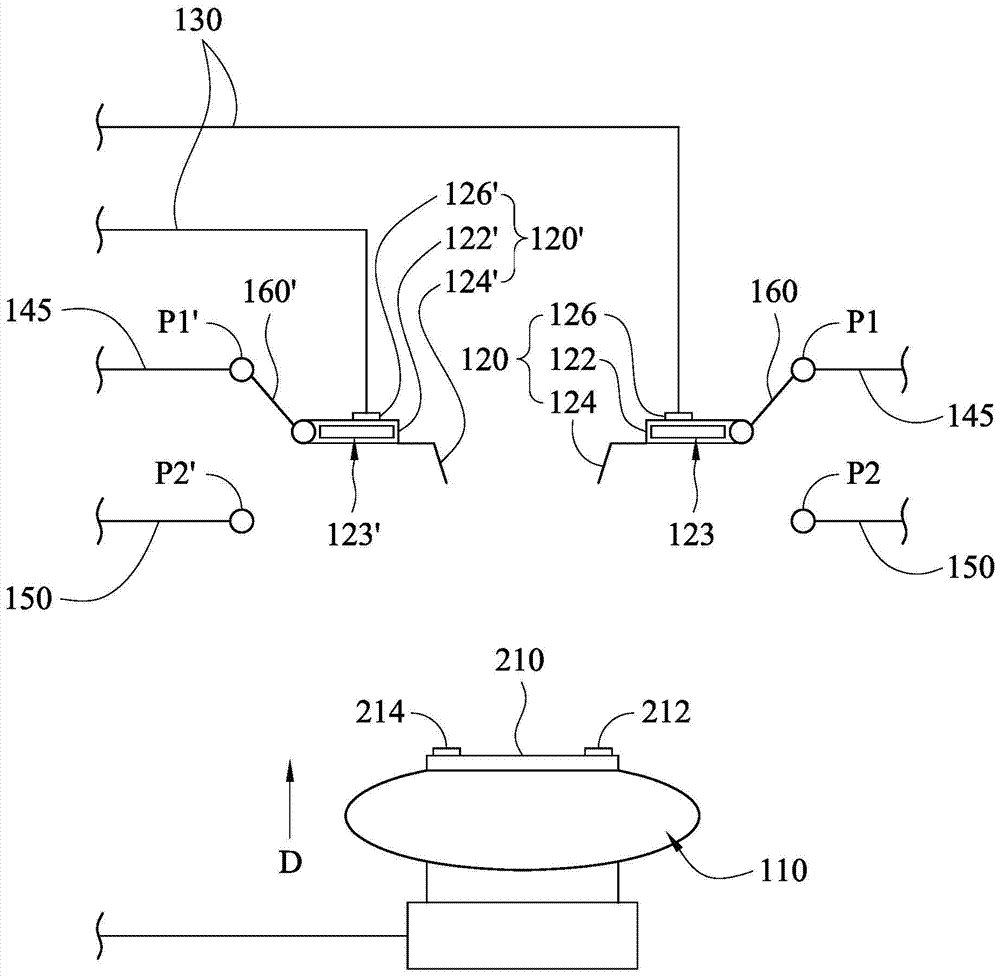

[0024] A number of implementations of the present invention will be disclosed below with the accompanying drawings, and many specific details will be described together in the following description for the sake of clarity. It should be understood, however, that these specific details should not be used to limit the invention. That is, in some embodiments of the invention, these specific details are not necessary. In addition, for the sake of simplification of the drawings, some conventional structures and elements will be shown in a simple and schematic manner in the drawings.

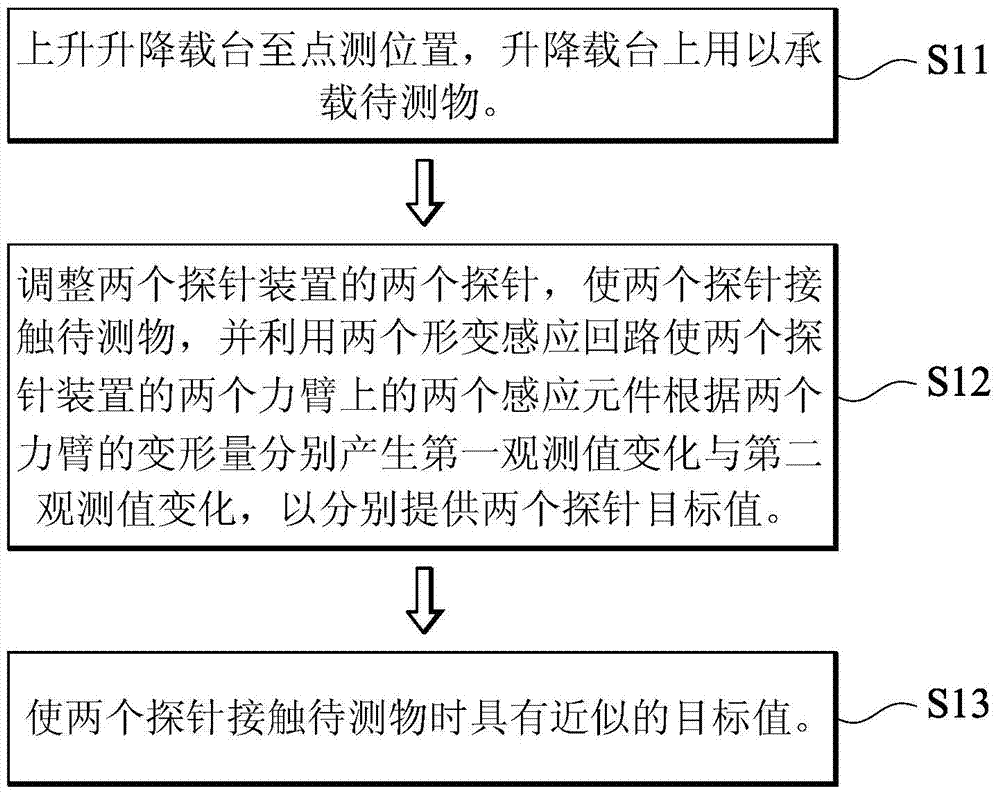

[0025] figure 1 It is a flowchart of a probe height adjustment method according to an embodiment of the present invention. Firstly, in step S11 , the lift platform is raised to the spot measurement position, and the lift platform is used to carry the object to be tested. Then in step S12, adjust the two probes of the two probe devices so that the two probes contact the object to be tested, and use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com