A kind of sine wave permanent magnet synchronous motor with low cogging effect and its manufacturing method

A cogging effect and synchronous motor technology, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, manufacturing motor generators, etc., can solve the problem of poor cogging effect inhibition and the influence of sine wave permanent Magnetic synchronous motor output efficiency and other issues to achieve the effect of improving stability, improving stability and control accuracy, and improving the back EMF waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

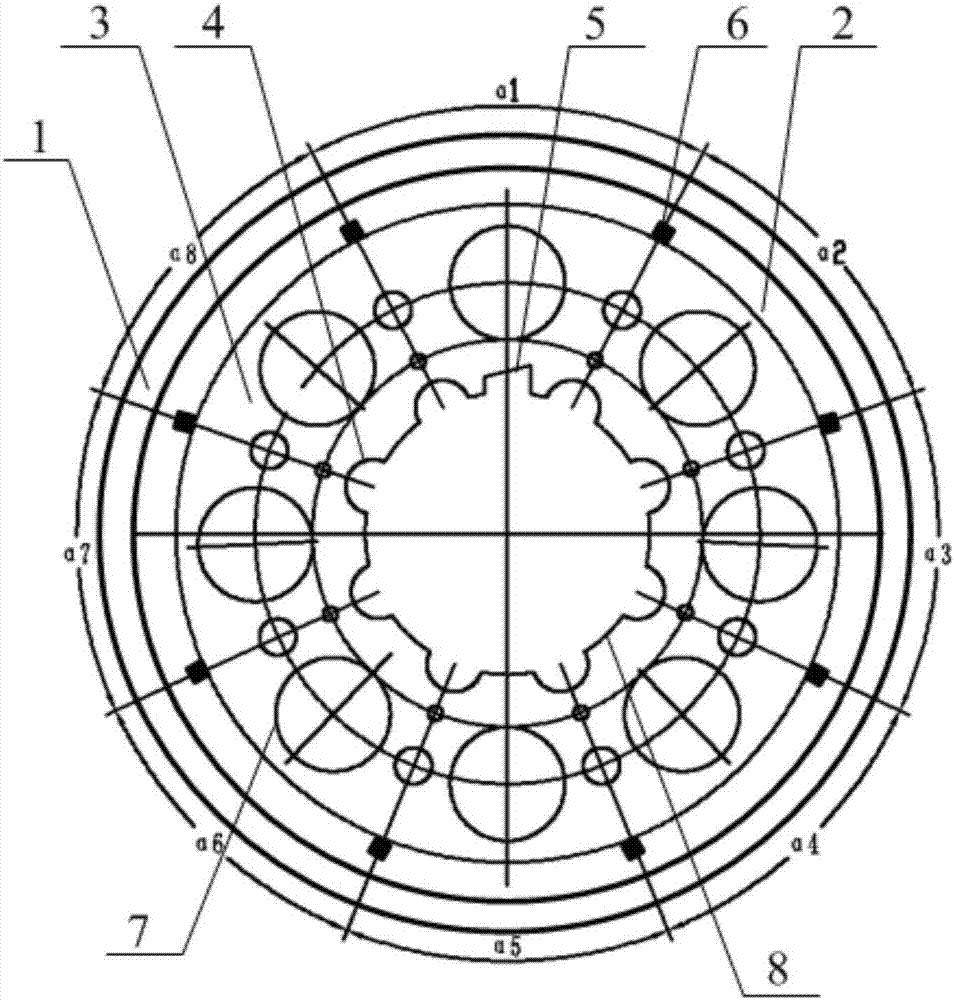

[0022] Such as figure 1 As shown, the sine wave permanent magnet synchronous motor with low cogging effect of the present invention includes: a semi-closed slot punched stator and a surface-mounted rare earth permanent magnet material excitation rotor. The sine wave permanent magnet synchronous motor is a three-phase motor and has a phase band. It is 60°, and there are 36 stator slots in the semi-closed slot punched stator.

[0023] The surface-mounted rare earth magnetic material excitation rotor includes a steel sleeve 1, eight magnets 2 and rotor punching pieces 3. Among them, a rotor shaft mounting hole 8 is provided at the center of the rotor blade 3, and eight semicircular synchronization notches 4 are provided on the circumferential edge of the rotor shaft mounting hole 8; and the outer circumference of the rotor blade 3 is provided There are eight positioning teeth 6, and eight pieces of magnetic steel 2 are glued and fixedly installed between two positioning teeth 6; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com