Built-in type permanent magnet synchronous motor

A permanent magnet synchronous motor, built-in technology, applied to synchronous machines, synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, etc., can solve the difficulty of designing multi-segment lines on the outer contour of the rotor and weaken the motor Noise and vibration, unsatisfactory application effects and other problems, to achieve the effect of improving the back EMF waveform, optimizing performance, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

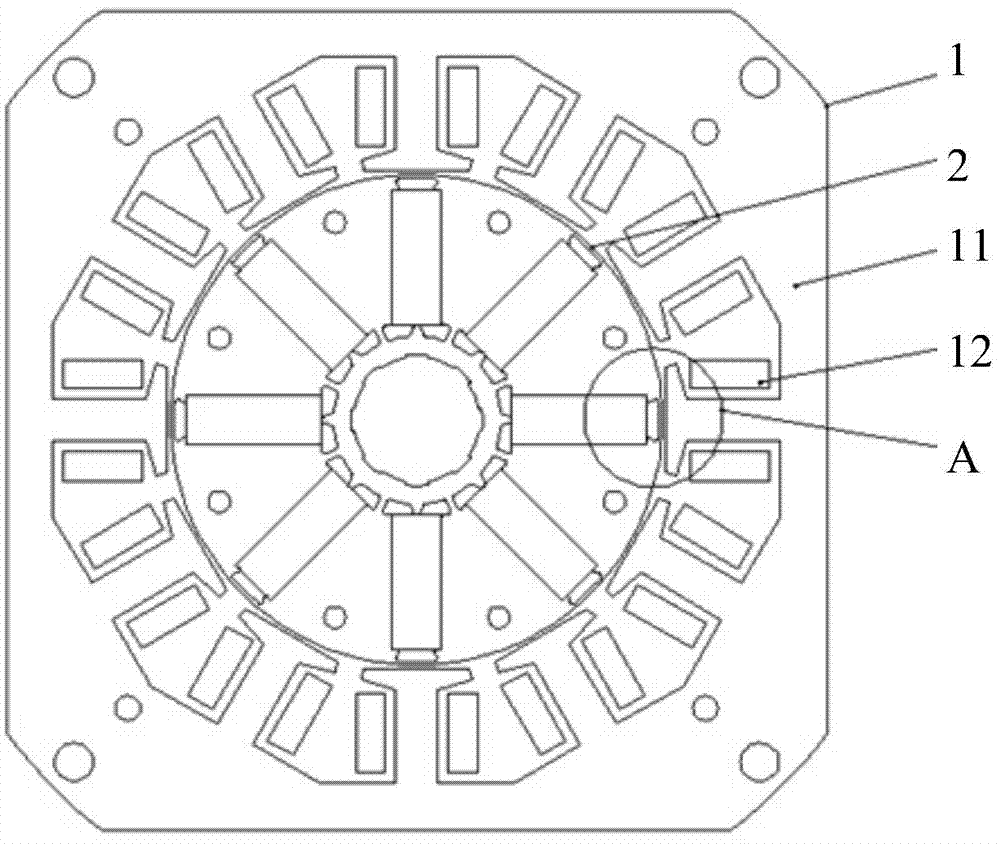

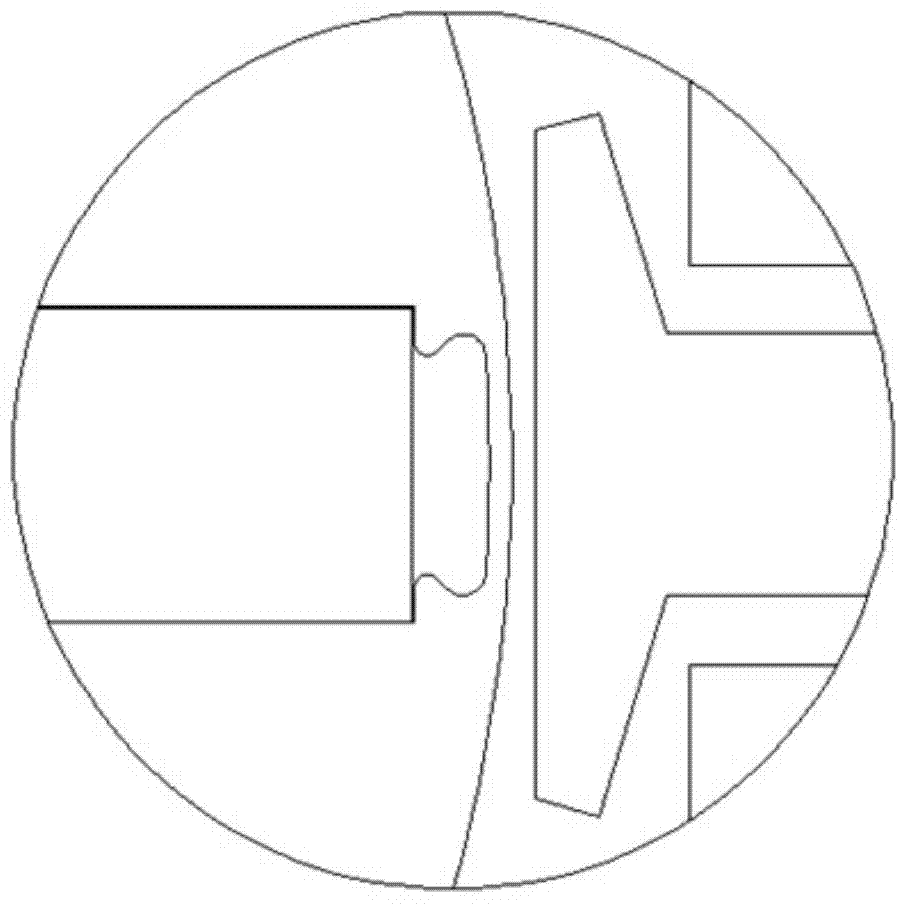

[0041] Please also see figure 1 and figure 2 , as shown in the figure, a built-in permanent magnet synchronous motor includes a stator 1 and a rotor 2. There is an air gap between the inner ring of the stator 1 and the outer ring of the rotor 2. The stator 1 includes a stator core 11 and a winding 12. The stator iron The side of the teeth of the core 11 opposite to the air gap has a linear structure, and the outer ring of the rotor 2 has a perfect circular structure, and there is an air gap space between the teeth and the outer ring of the rotor. In this way, an uneven air gap is formed, which can effectively optimize the performance of the motor, significantly improve the back EMF waveform of the motor, effectively weaken the cogging torque, and suppress the noise and vibration of the motor.

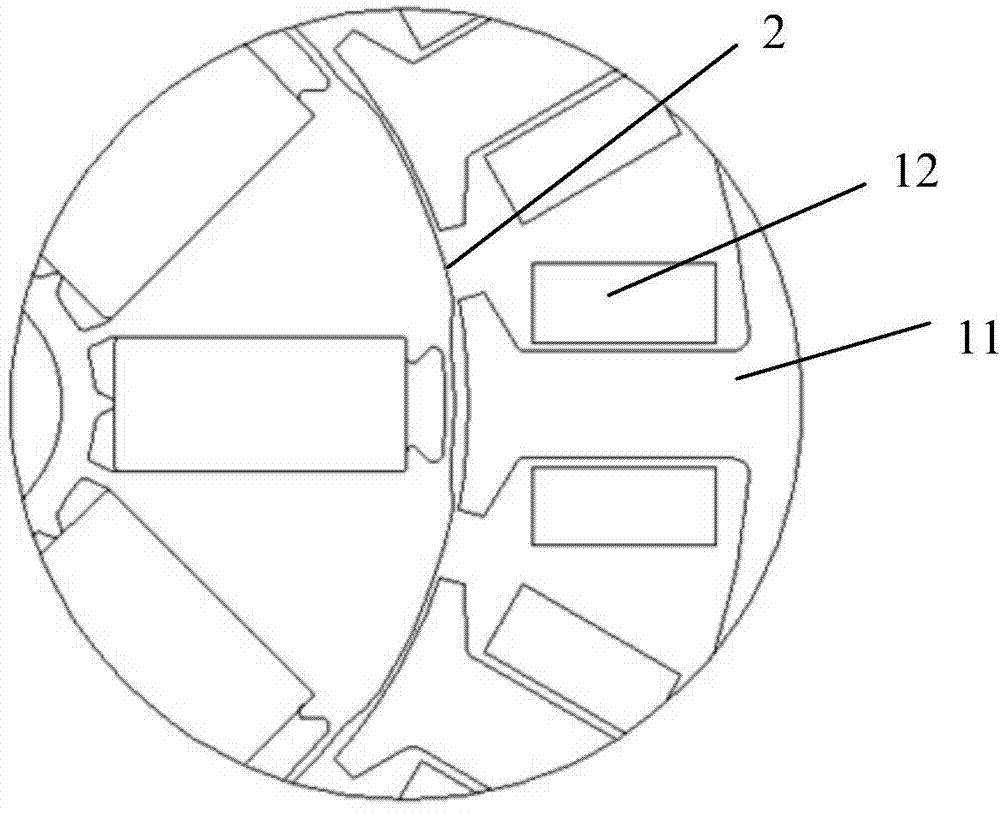

[0042] Correspondingly, such as image 3 As shown, the part of the stator teeth facing the air gap is a concentric arc edge, and the outer contour of the rotor is a polyline, forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com