Permanent magnet switch magnetic flux linkage motor

A technology of permanent magnet switch and flux linkage, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of increased production scrap rate, deformation of the inner circle of the stator, deformation of the punching plate, etc., and achieves optimal feedback. Potential waveform, effect of reducing harmonic content, increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention provides a novel permanent magnet switch flux linkage motor with simple structure. More particularly, the present invention mainly adopts the magnetic isolation hole to replace the conventional magnetic isolation bridge, so that the mechanical strength of the stator core is increased and the processing is convenient. Preferred specific embodiments of the present invention will be described in detail below.

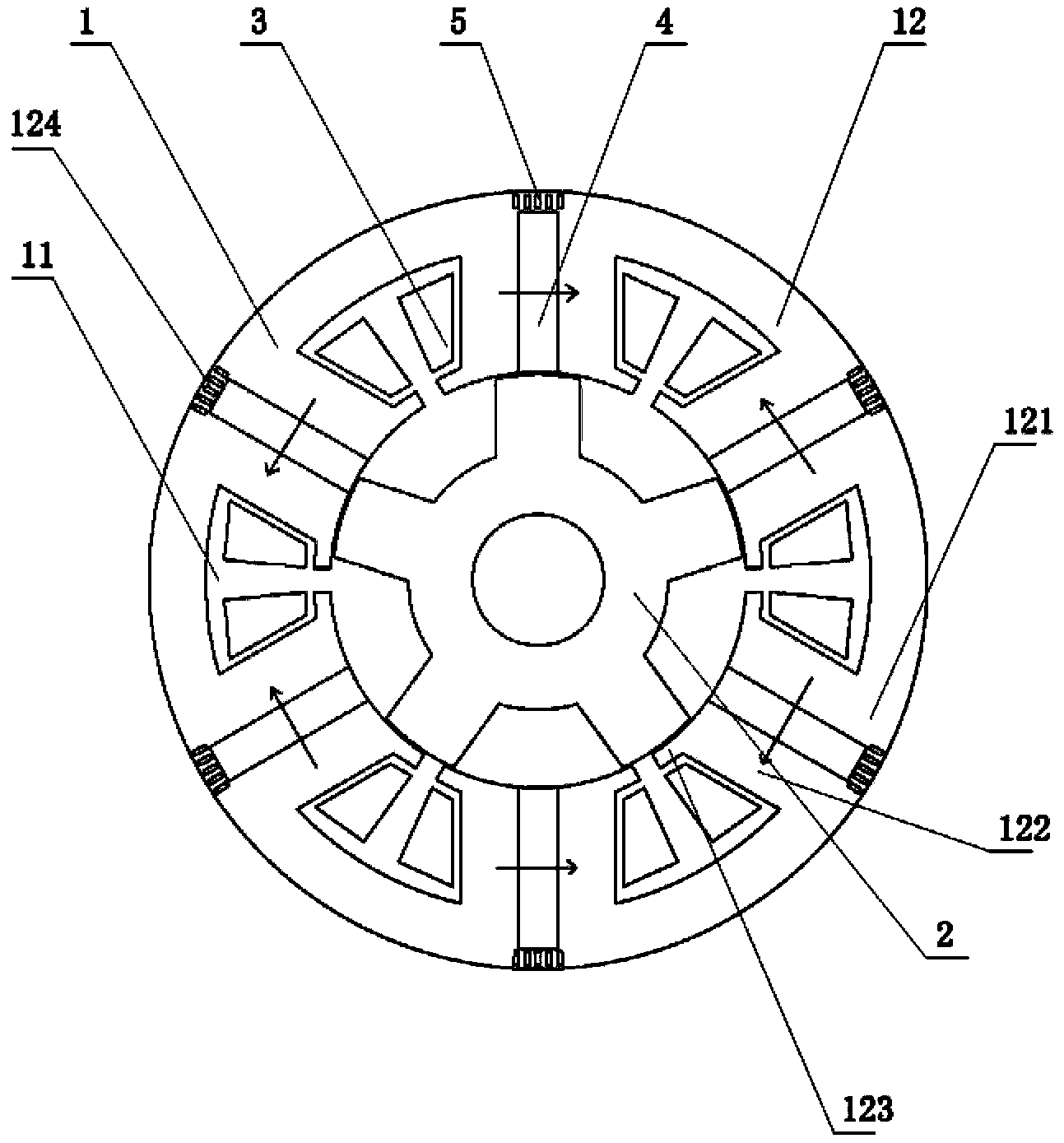

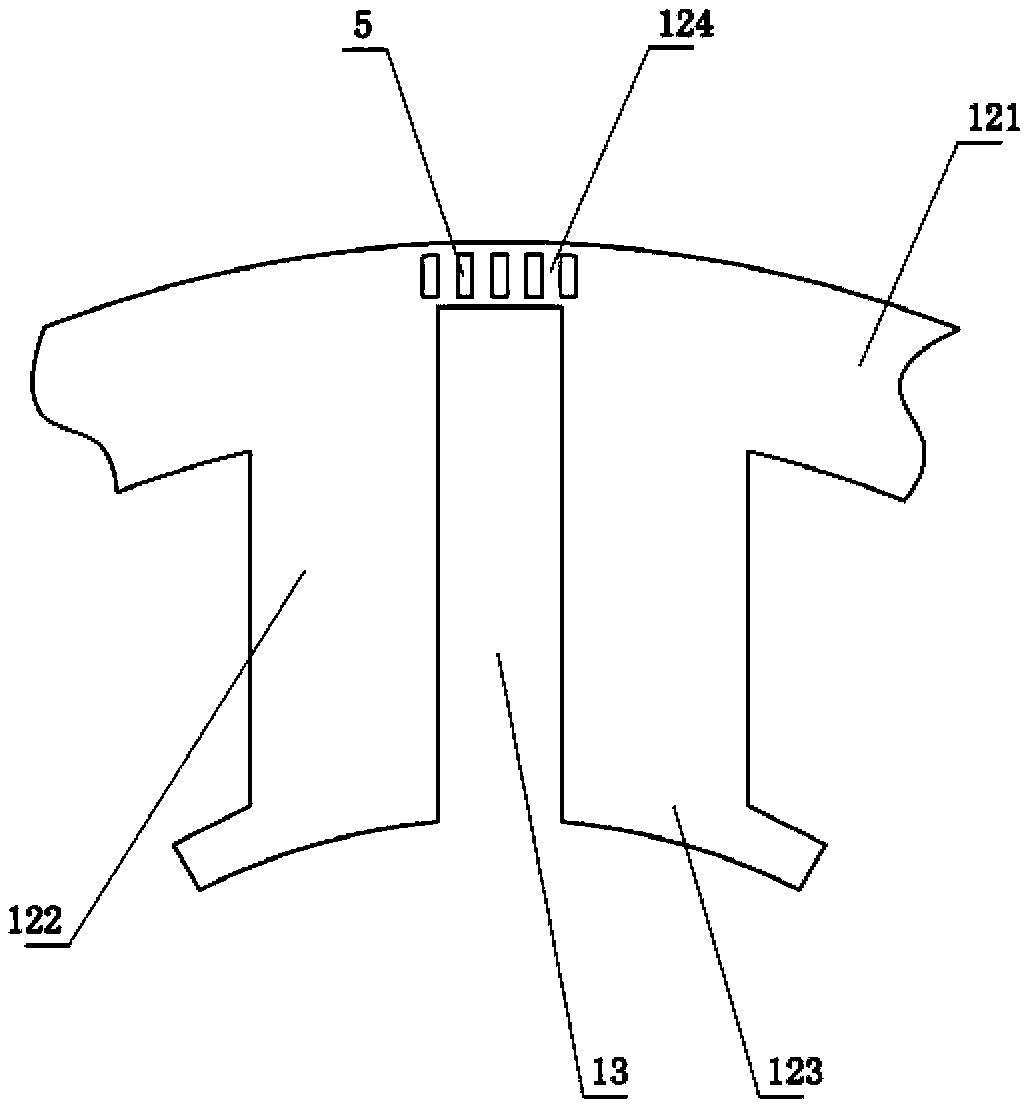

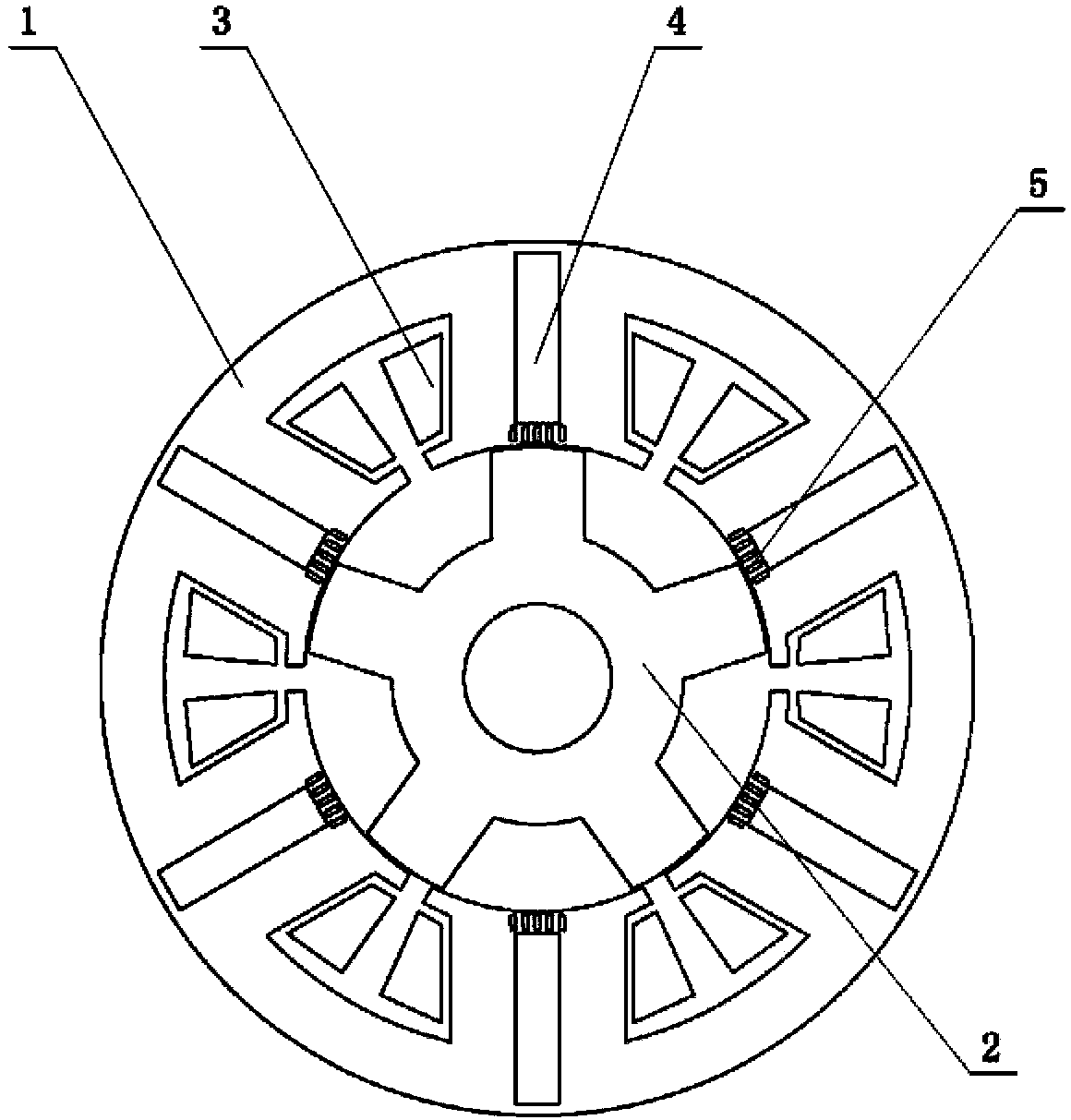

[0031] see Figure 1 to Figure 7 , the present invention provides a permanent magnet switch flux linkage motor, which includes a stator core 1, a rotor core 2, an armature winding 3 and a permanent magnet 4, and the stator core 1 includes several The stator slots 11 evenly distributed in the circumferential direction and the stator teeth 12 between two adjacent stator slots 11 are provided with permanent magnet slots 13 for placing permanent magnets 4 on the stator teeth 12, and the armature winding 3 is arranged on the In the stator slot 11 , a magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com