Multifunctional bagging machine

A packaging machine and multi-functional technology, which can be used in packaging, baling machines, harvesters, etc., can solve the problems of reducing production efficiency, cumbersome procedures, and inability to collect straw, and achieve the effect of reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

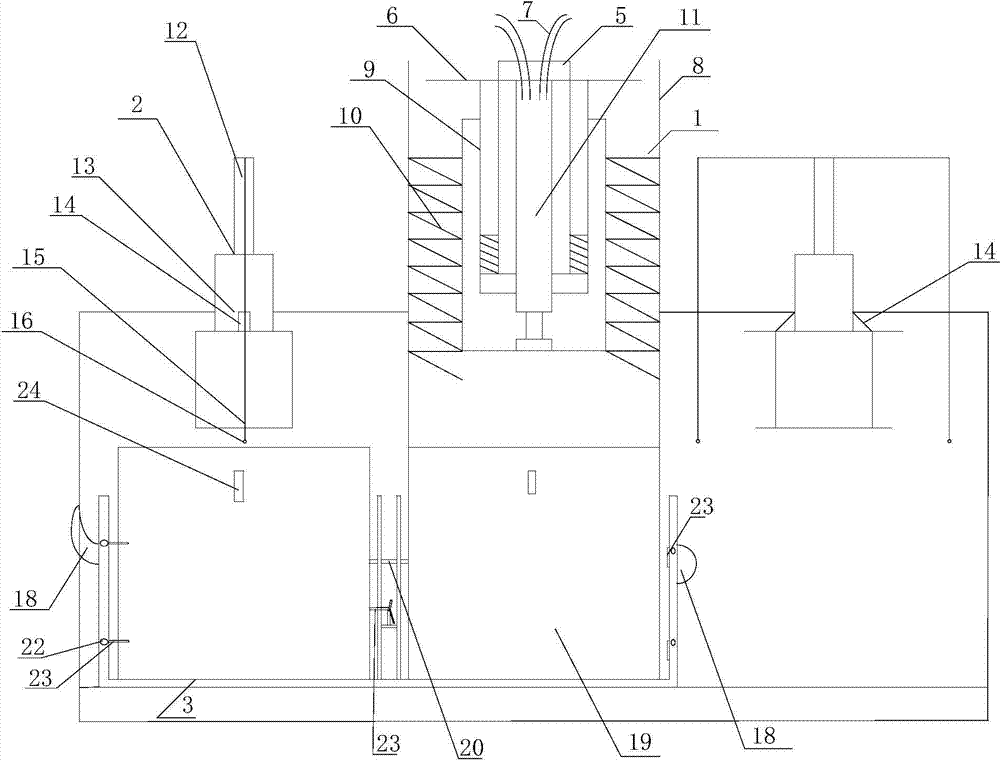

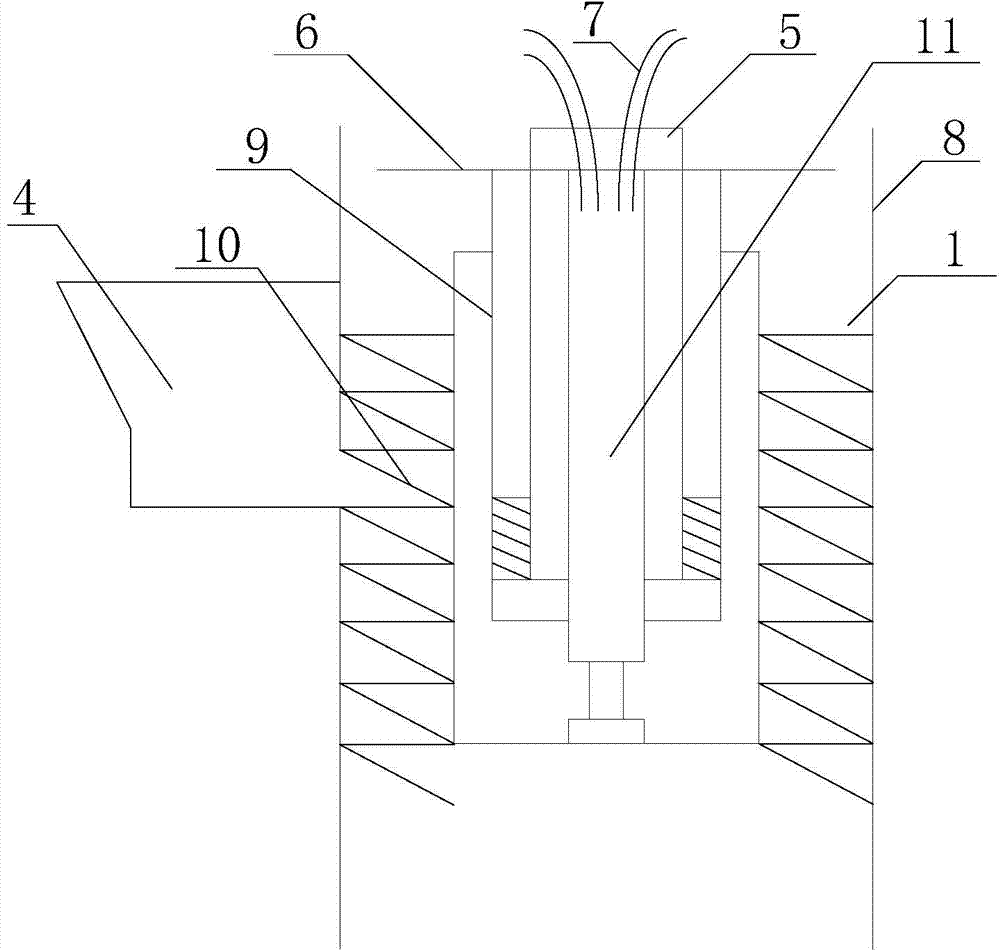

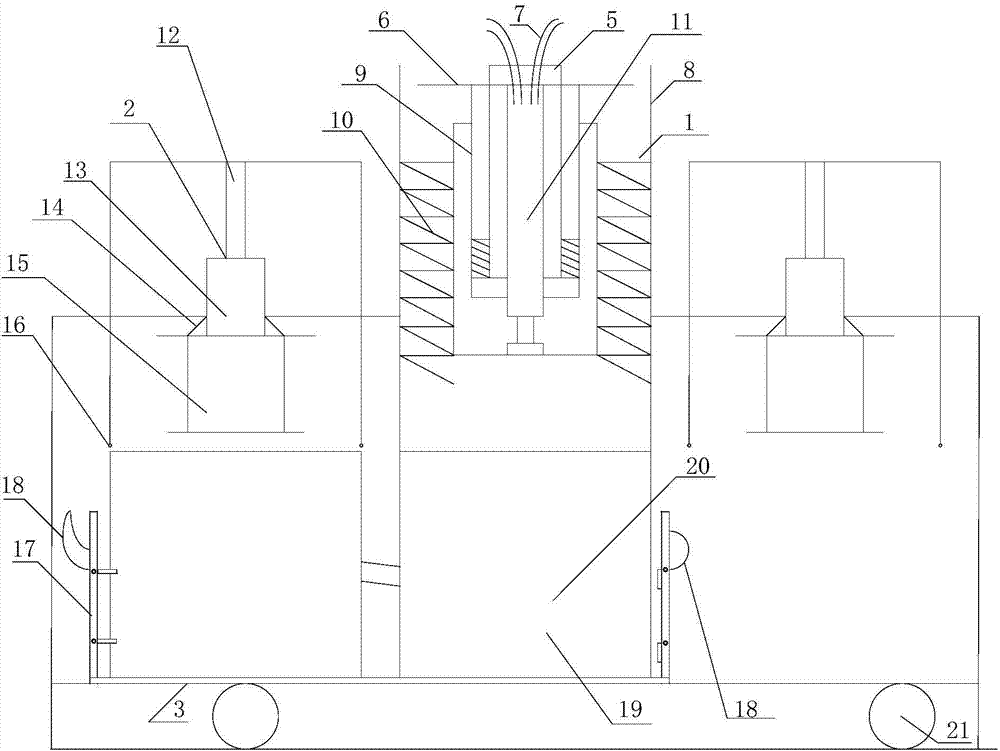

[0018] see Figure 1 to Figure 3 , a multi-functional packaging machine, including a bracket, a screw feeder 4 connected to the corn stalk crushing bin of a corn harvester, a feed compactor 1 connected to the screw feeder 4, and a feed compactor 1 arranged on a feed compactor Packing and dehulling devices 2 on both sides of the device 1 and a mobile guide packing car 3 located at the lower part of the feed compactor 1 and the packing and dehulling device 2, the feed compactor 1 includes a feed compactor housing 8 and the fixed shaft 5 fixed on the bracket and inserted into the feed compactor housing 8, the upper end of the fixed shaft 5 is equipped with a drive disc 6, the drive disc 6 is connected with the hydraulic motor or hydraulic pump through a reducer, and the fixed shaft 5. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com