Yield measurement and base cutter height control systems for a harvester

A harvester and yield technology, applied in the direction of cutters, harvesters, volume measuring instruments/methods, etc., can solve problems such as difficulty in obtaining yield information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

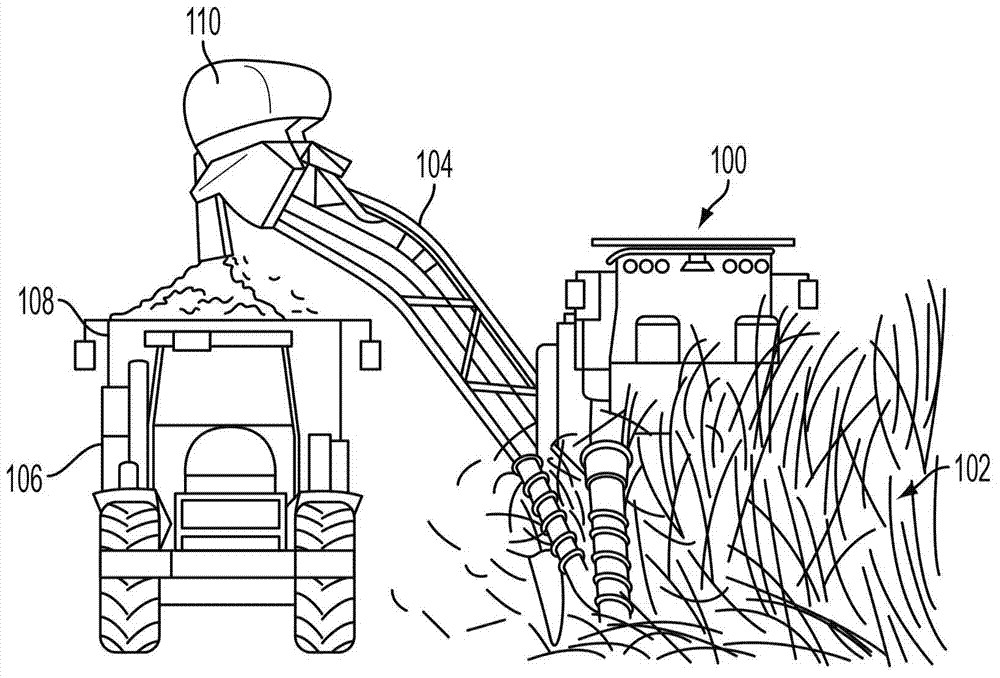

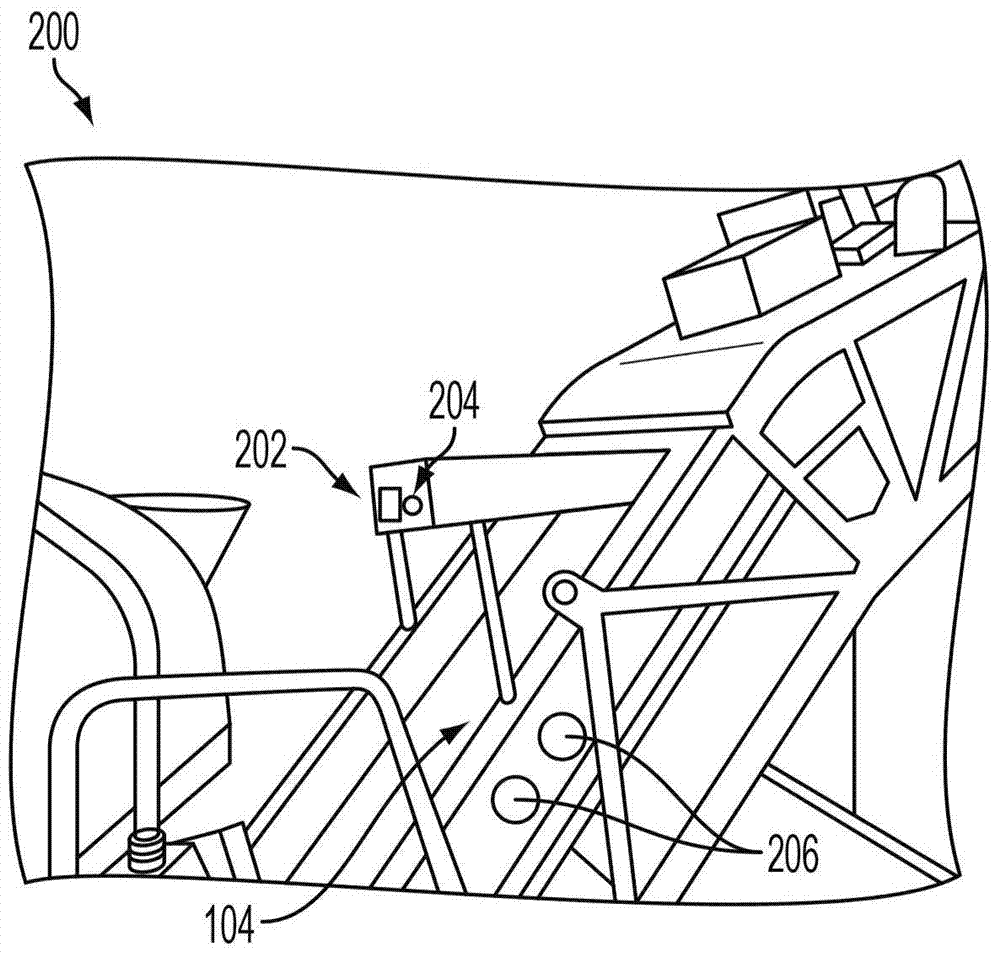

[0029] Yield Measurement System

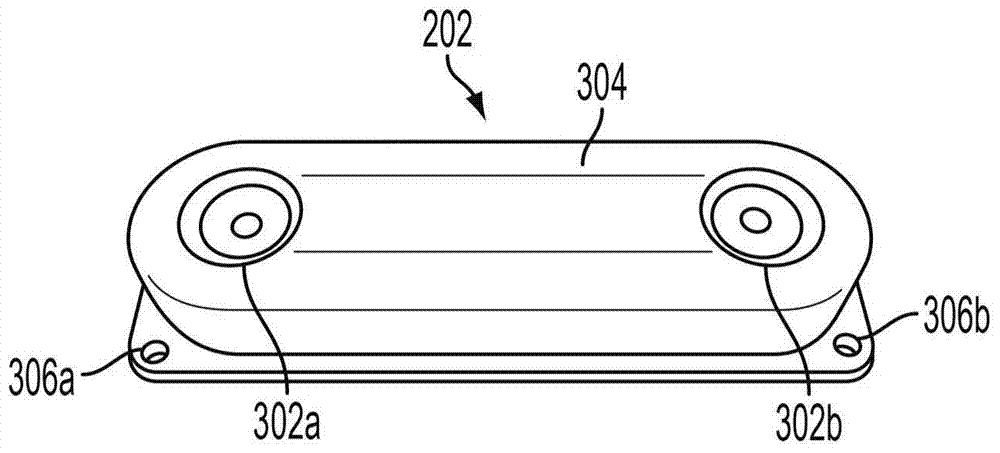

[0030] Certain aspects and features of the present disclosure relate to real-time yield measurement systems for harvesters (eg, combines). The yield measurement system can include a 3D sensor (eg, a stereo camera system) coupled to the elevator of the harvester. The 3D sensor is capable of detecting material (eg, sugar cane, potatoes, sugar beets, tomatoes, or other crops) passing over a portion of the elevator. The yield measurement system can process data from the 3D sensor to measure the net volume of material carried by the elevator in real time (eg, substantially while harvesting).

[0031] In some examples, the yield measurement system is capable of distinguishing the crop carried by the elevator from foreign material (eg, foreign material). The yield measurement system is capable of distinguishing crop from foreign matter by determining one or more characteristics (eg, size, color, shape, and texture) of the material carried by the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com