Double-wheel coaxial differential self-impacting type grinder

A pulverizer, coaxial technology, applied in the direction of grain processing, etc., can solve the problems of increased wear and tear of the projectile wheel, reduction of the effective impact rate of mineral materials, and scrapping of the projectile wheel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

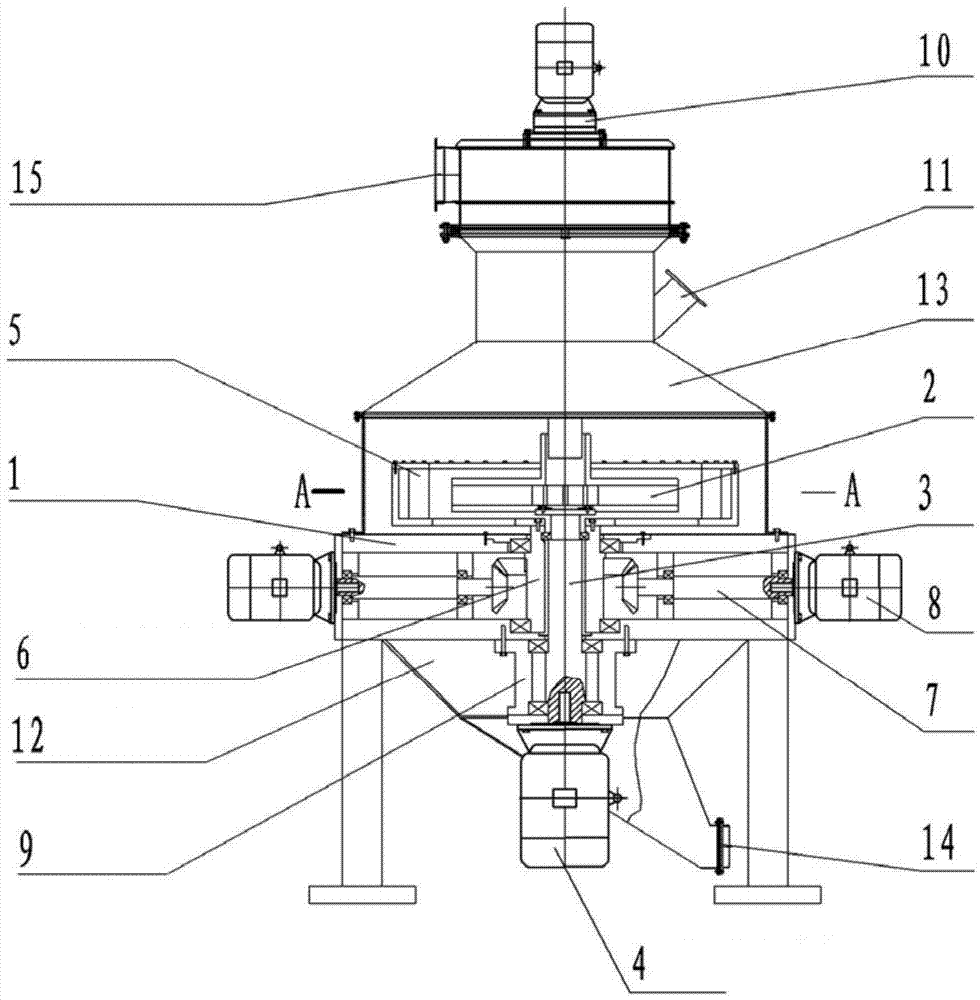

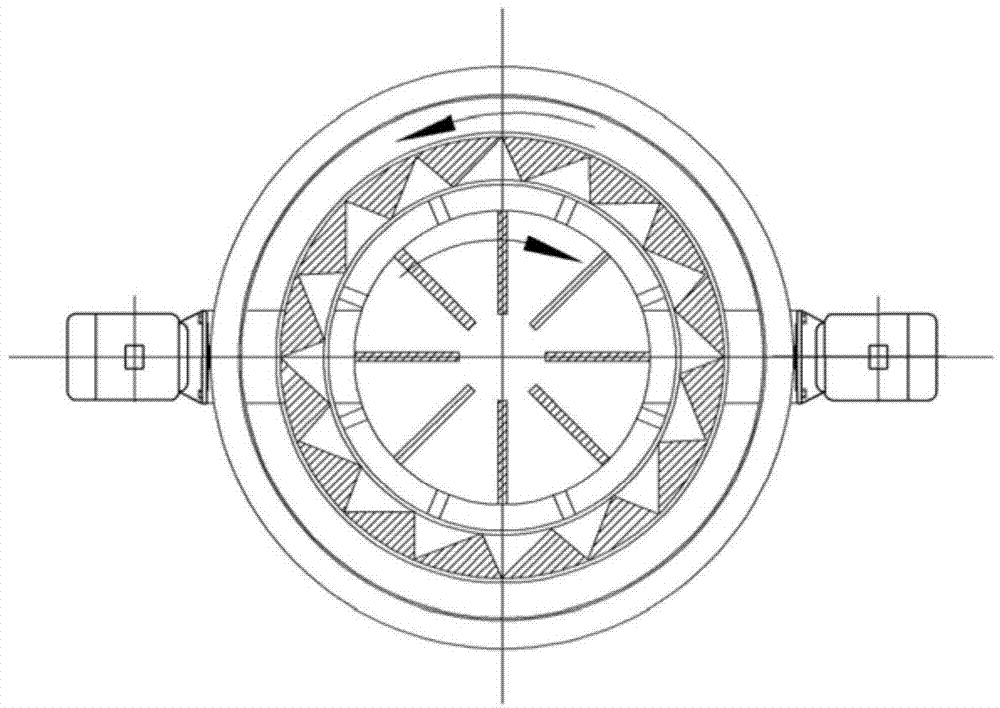

[0018] Such as figure 1 with 2 As shown, the double-wheel coaxial differential self-impacting mill of the present invention mainly includes a frame 1, and also includes a coaxial projecting wheel 2 and self-impacting wheel 5, the self-impacting wheel main shaft 6 is a hollow shaft, and the projecting wheel Main shaft 3 is placed in the hollow shaft, therefore, the projecting wheel is inside, and the self-beating wheel is outside. The inner side of the upper end of the hollow shaft and the upper end of the main shaft of the projecting wheel are installed and fixed with high-speed bearings to ensure the stability of the two shafts when rotating, and the upper and lower ends of the outer side of the hollow shaft are vertically installed in the center of the frame with bearings. The projecting wheel is fixedly installed on the projecting wheel main shaft upper end with a straight key connection bolt, and the projecting wheel main shaft lower end is installed on the base with a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com