Amplitude Limiting System for Insulated Aerial Work Platforms

A high-altitude work platform and range-limiting technology, which is applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problems of hidden safety hazards and manual manual control of the operation range, so as to improve safety, prevent overload operation, and solve the problem of range. The effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

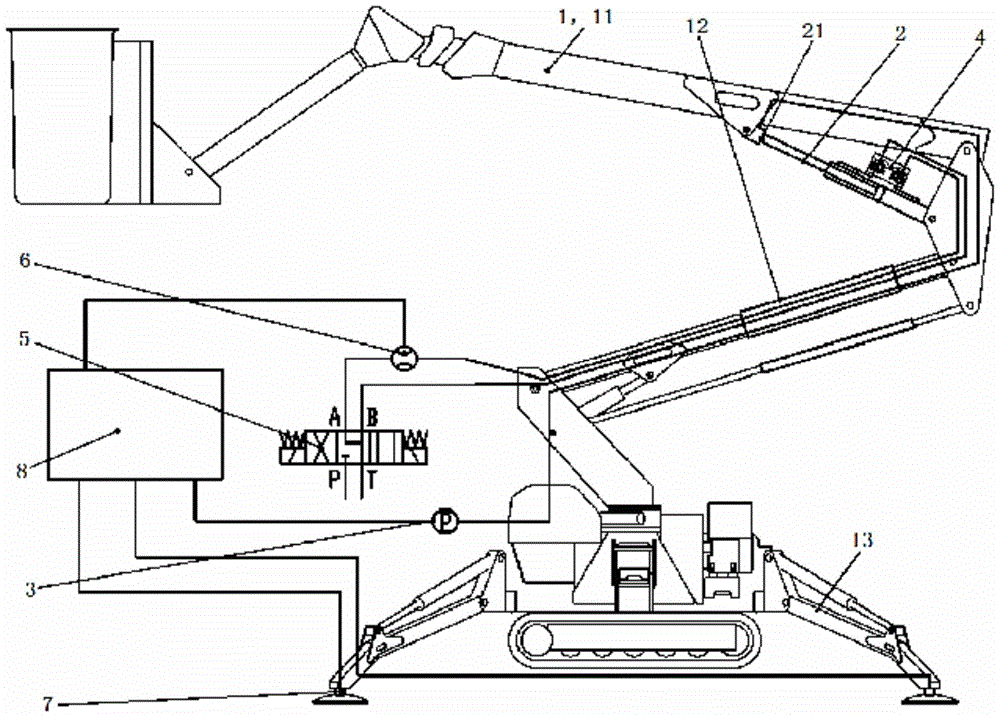

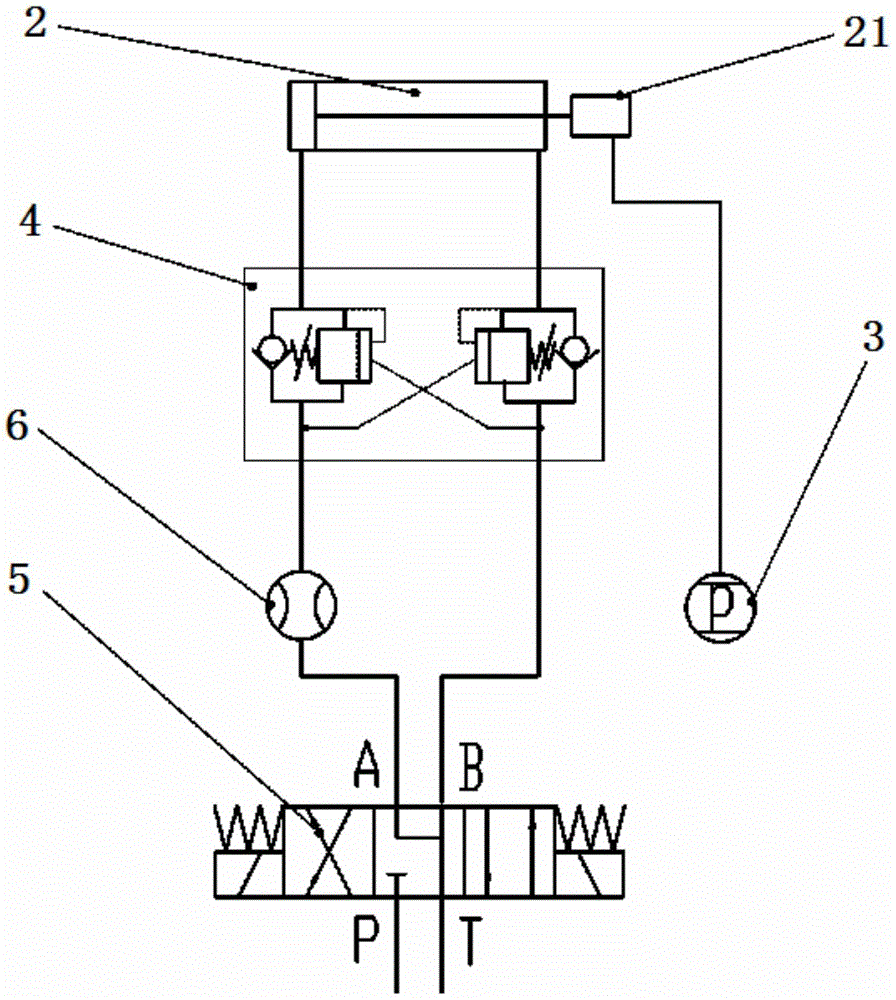

[0024] See figure 1 and figure 2 , the amplitude limiting system of the insulating aerial work platform of this embodiment is mainly composed of an insulating aerial work platform 1, a luffing cylinder 2, a first pressure sensor 3, a balance valve 4, a reversing valve 5, a flow meter 6, and a second pressure sensor 7 and controller 8.

[0025] The insulated aerial work platform 1 is an insulated aerial work platform with a hybrid boom structure. The insulated aerial work platform 1 has a telescopic arm 11 , an insulating folding arm 12 and a telescopic support leg 13 .

[0026] The luffing cylinder 2 is installed between the telescopic arm 11 and the insulating folding arm 12, and the telescopic arm 11 is driven by the luffing cylinder 2 to realize the luffing action. The luffing oil cylinder 2 is provided with an oil pressure chamber 21 , and the pressure on the oil pressure chamber 21 is the pressure on the luffing oil cylinder 2 .

[0027] The first pressure sensor 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com