Production equipment for low-emission sulphur red mud bituminous concrete modifier

A technology of asphalt concrete and production equipment, which is applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., to achieve the effects of convenient operation, high production efficiency and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

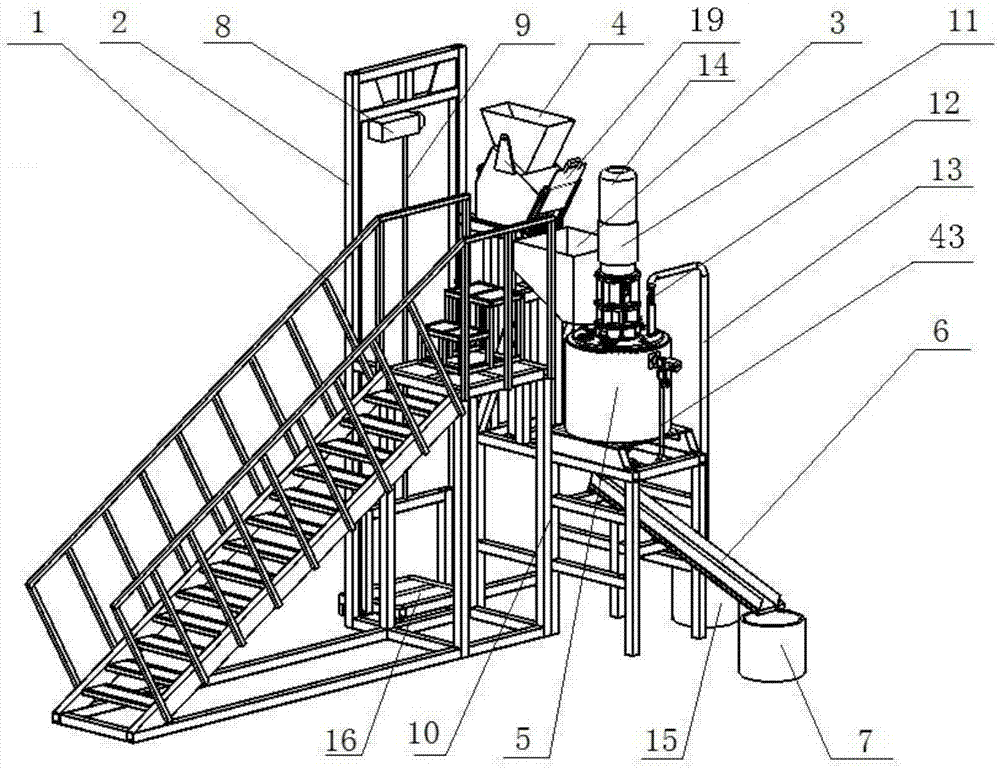

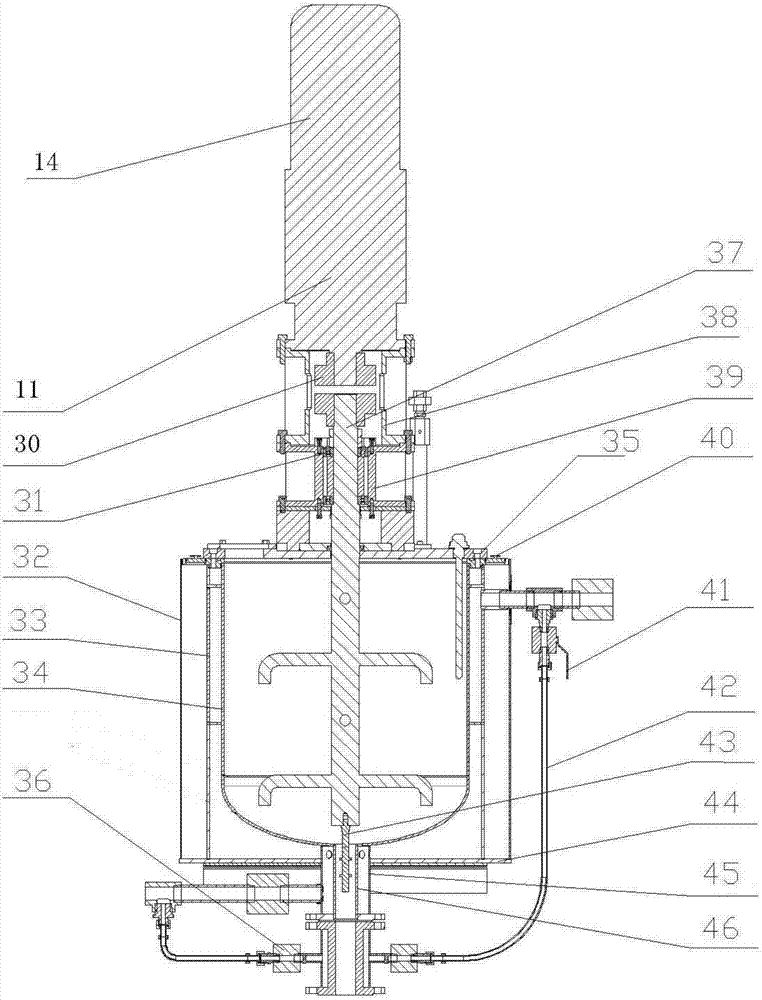

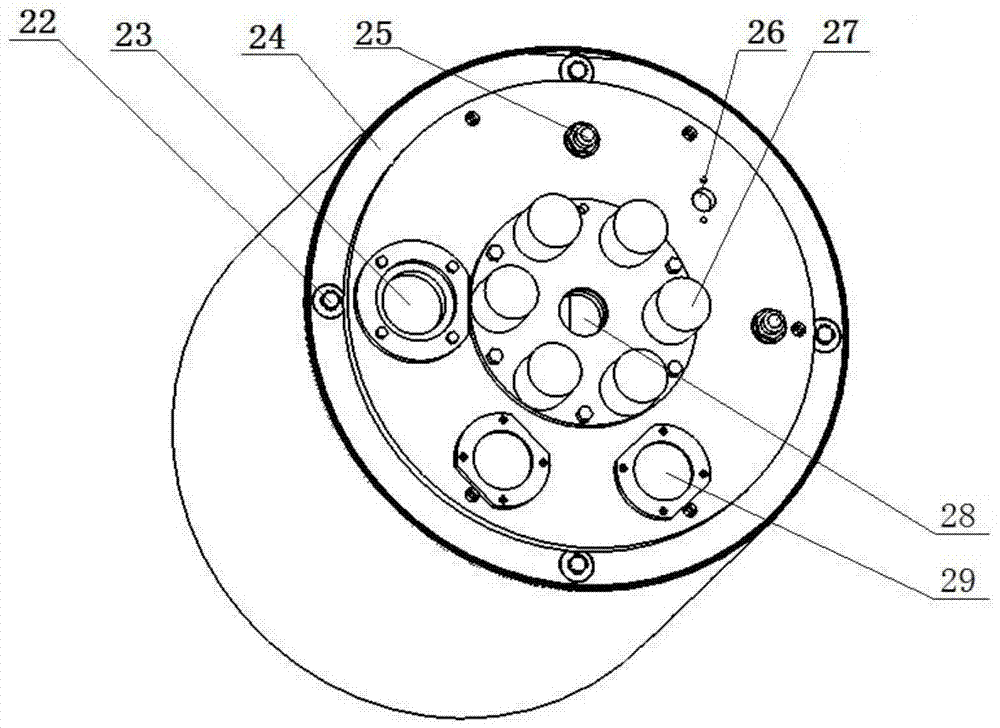

[0025] Such as figure 1 , figure 2 As shown, a production equipment for low-emission sulfur red mud asphalt concrete modifier, including escalator 1, hoist 2, feeding funnel 3, oven 4, stirring tank 5, U-shaped groove 6, barrel 1 7, bracket 10. Reducer 11, air duct 13, motor 14, barrel 2 15 and motor base 38, the stirring kettle 5 and oven 4 are installed on the support 10, and the escalator 1 and hoist 2 are arranged on one side of the support 10. Side, the upper part of the stirring tank 5 is provided with a feed funnel 3, an air duct 13 and a motor seat 38, the air duct 13 is provided with a joint and a ball valve switch 12, and the lower part of the air duct 13 is provided with a barrel two 15, and the deceleration The device 11 and the motor 14 are installed on the motor base 38, the inside of the motor base 38 is provided with a shaft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap