Industrial production of new high-efficiency and energy-saving building roof panels and manufacturing method

A high-efficiency, energy-saving, factory-like technology, applied in the direction of roofing, construction, building structure, etc., can solve the problems of not easy to age, limited strength and thermal insulation effect, etc., to delay aging, avoid the volatilization of inherent gas odor, and achieve high interlayer strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

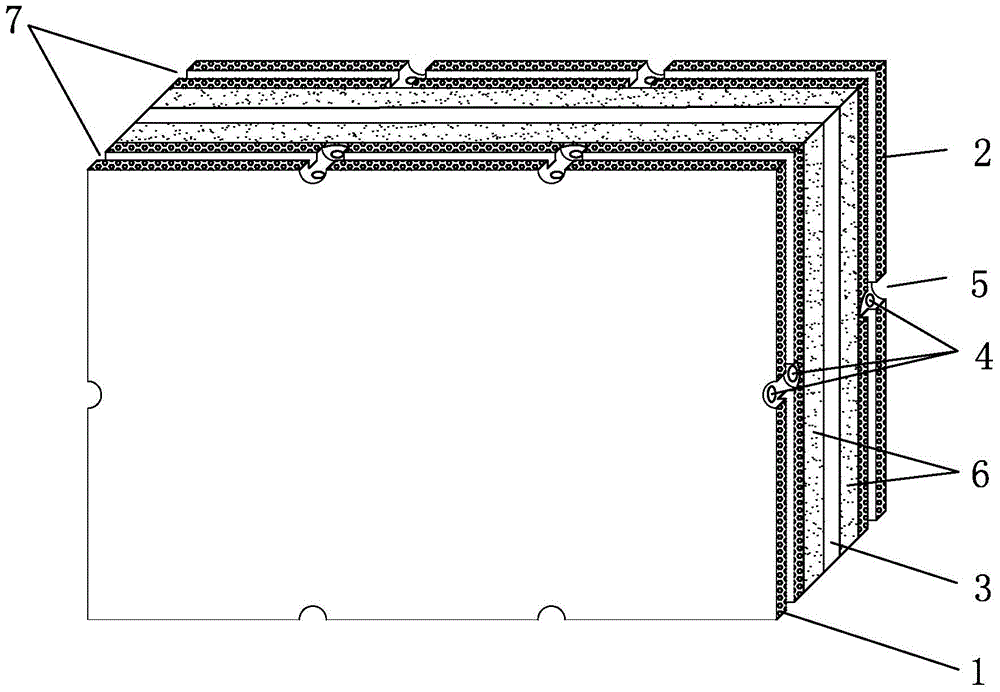

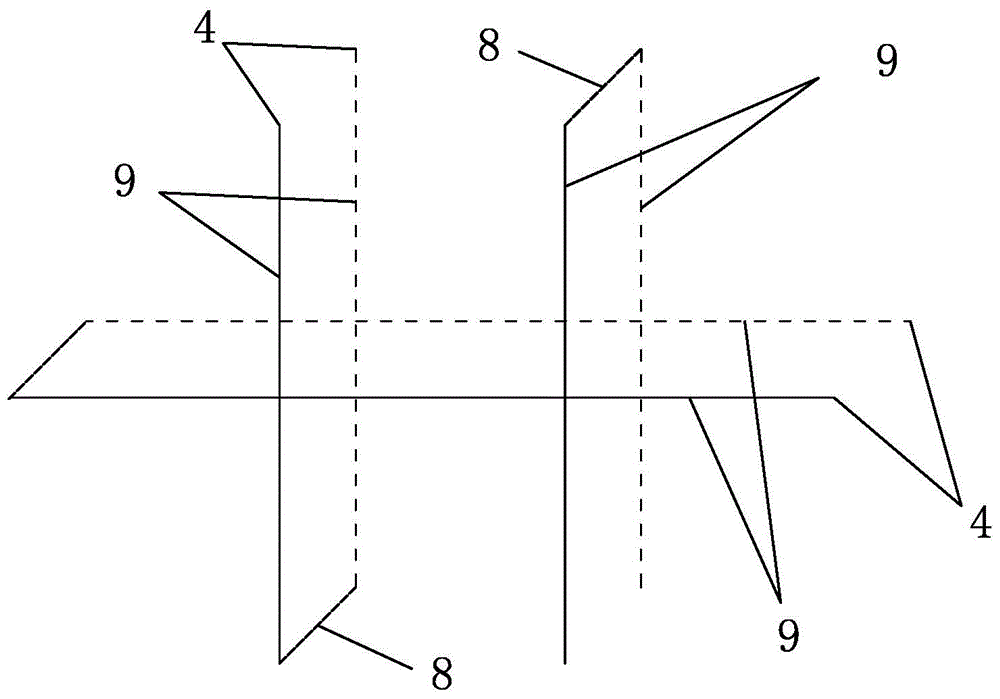

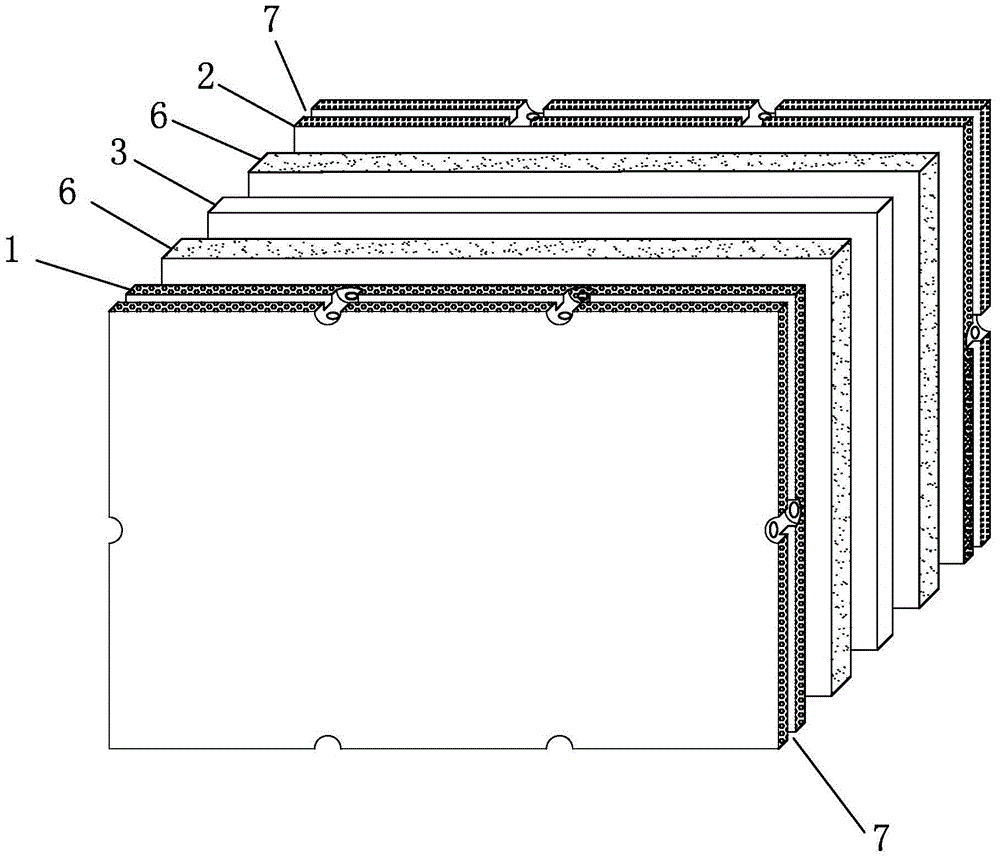

[0038] Embodiment 1: The factory production of the present invention is novel high-efficiency energy-saving building roof panel, as attached figure 1 , attached image 3 , attached Figure 9 As shown, it includes an outer layer 1 and an inner layer 2 made of metal plates or composite cement or concrete, and the outer surface of the outer layer is a plane structure or a curved surface structure or a tile-like structure; An intermediate structural layer 3 made of organic thermal insulation materials; when the intermediate structural layer 3 is set as one layer, both sides of the intermediate structural layer 3 are in direct contact with the outer layer 1 and the inner layer 2, or the intermediate structural layer 3 is in direct contact with the outer layer 1 and the inner layer 2. A thermal insulation layer 6 made of inorganic thermal insulation material is arranged between the inner layers 2; when the intermediate structural layer 3 is set to two or more layers, an interval laye...

Embodiment 2

[0050] Embodiment 2: The manufacturing method of the novel high-efficiency energy-saving building roof panel of the present invention industrialized production, as attached Figure 10 , attached Figure 11 , attached Figure 12 As shown, the two ends of the bolt rod 31 are symmetrically placed in the bolt holes 32 on the intermediate structural layer 3, and then one or two intermediate structural layers 3 are placed between the two templates 11; the intermediate structural layer 3 is two layers At the same time, an interval is set between the intermediate structural layers 3, and the pre-mixed foamed cement insulation material slurry is poured into the space between the two formworks 11 and the two intermediate structural layers 3 and between the two intermediate structural layers 3; When the structural layer 3 is one layer, the ready-mixed foamed cement insulation material slurry is poured into the gap between the two formworks 11 and the middle structural layer 3, or the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com