Environmentally friendly stainless-steel-imitated wire-drawing color-coated steel plate and manufacturing method thereof

An environmentally friendly stainless steel imitation technology, applied in chemical instruments and methods, metal material coating technology, coating, etc., can solve problems such as difficult installation, high cost, and non-environmental protection, and achieve convenient and fast installation, reduce labor costs, Easy to tear off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

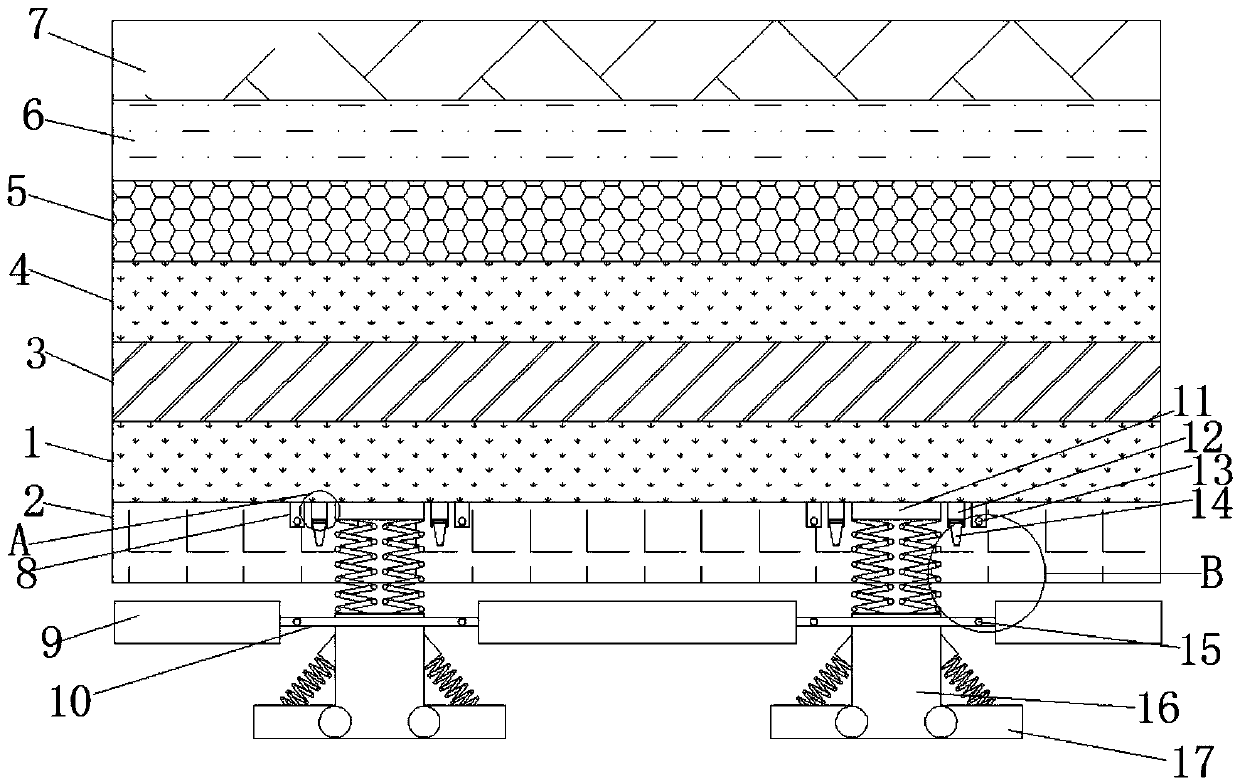

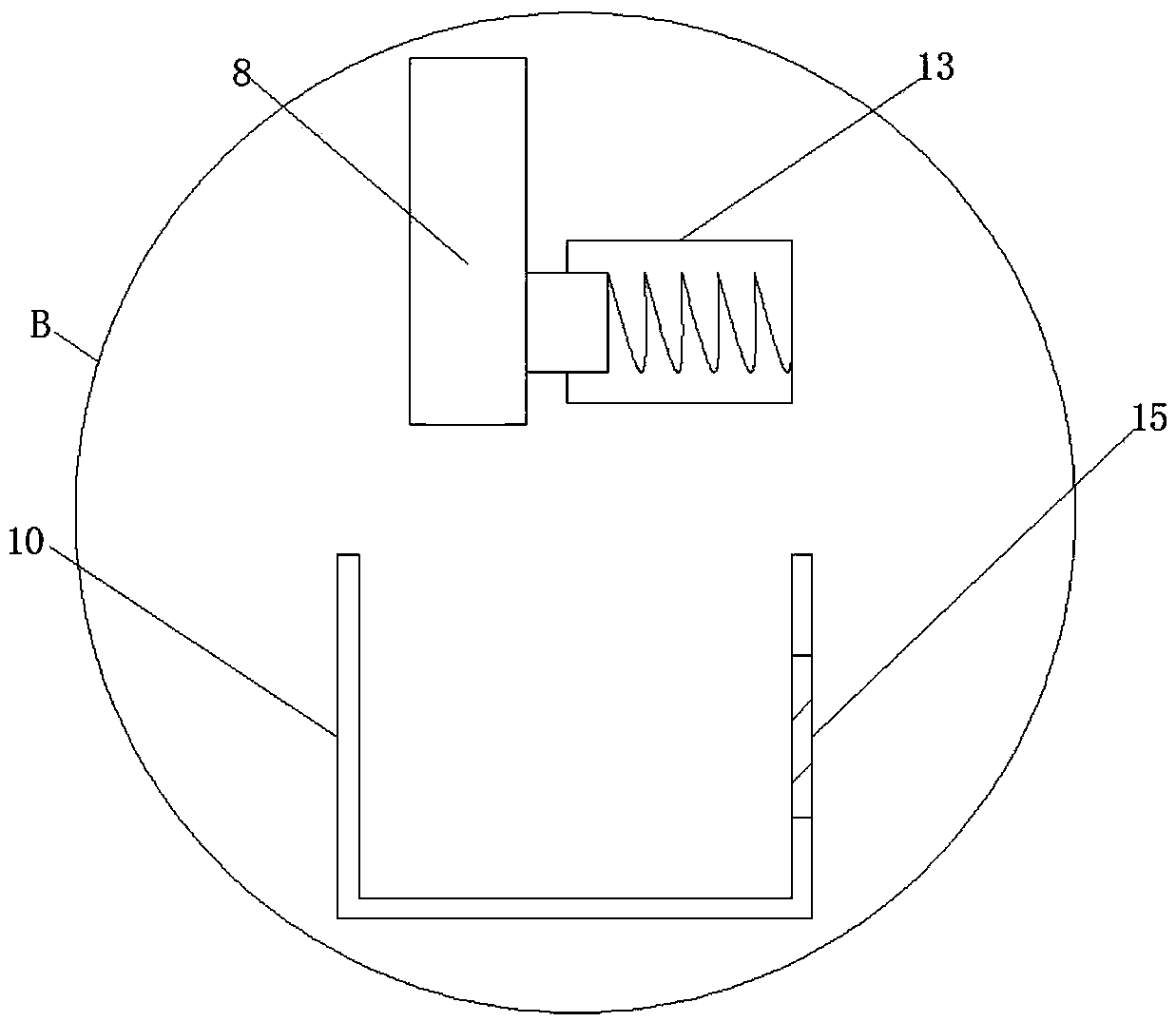

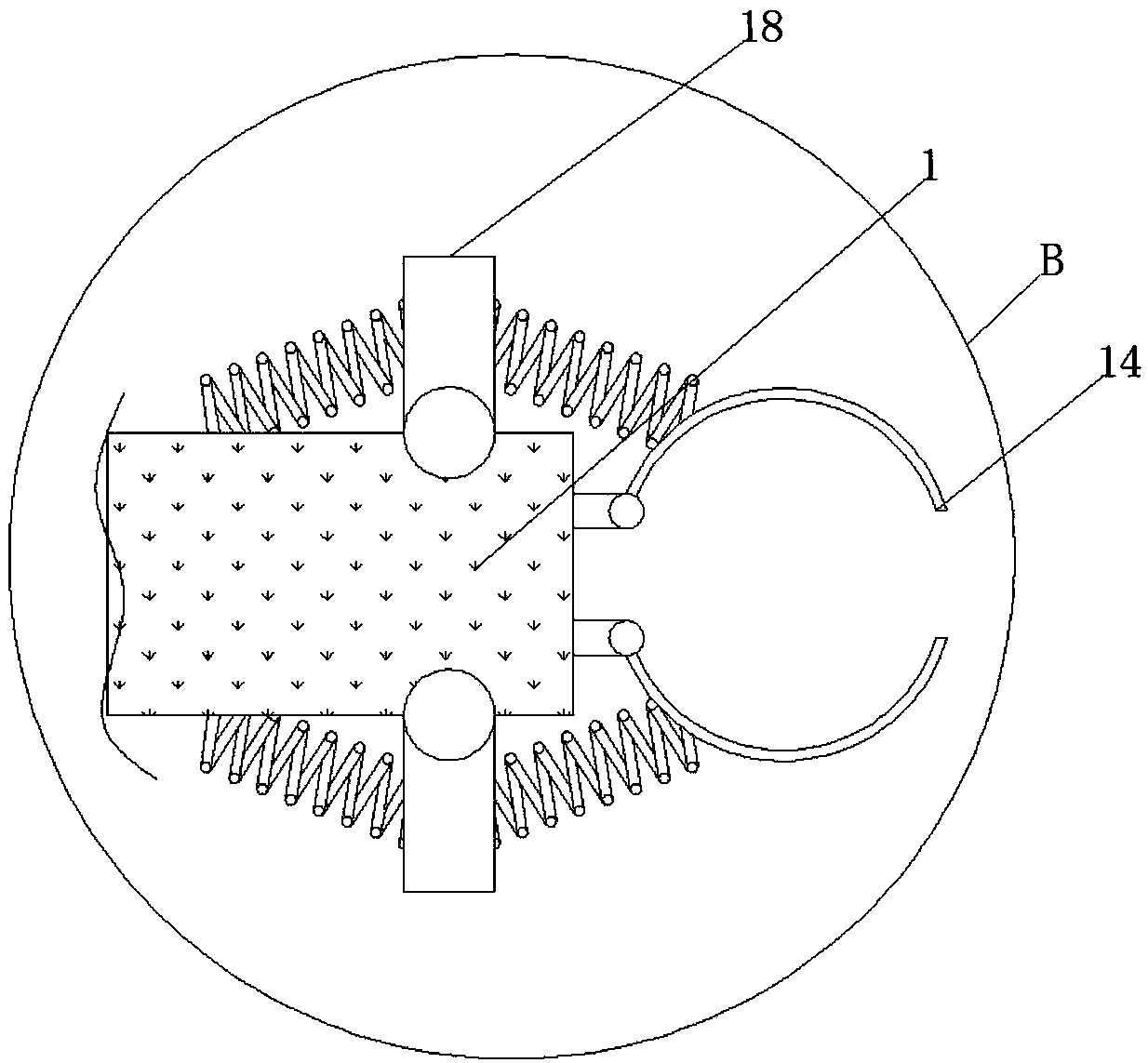

[0037] Embodiment 1: When working, when installing the coated steel plate, the personnel align the base 16 with the opening on the installation surface 9, and press the coated steel plate downwards. At this time, the base 16 moves downward with the rotating rod 17, and moves to the opening of the opening. position, the rotating rod 17 is forced to rotate upwards. At this time, the spring is compressed by force, and the rotating rod 17 moves closer to the middle, and continues to press the coated steel plate, and the rotating rod 17 is completely pushed out of the opening, and then the spring is no longer stressed and returns to its natural state. , bounce the rotating rod 17 to the horizontal position, then the personnel pull the coated steel plate upwards, press the rotating rod 17 under the opening, and then continue to press the coated steel plate downwards, so that the lower passivation layer 1 is close to the fixed rod 10, at this time the support block 11 The spring on on...

Embodiment 2

[0038] Example 2: S1, choose to use DC01, DC02, DC03, DC04 hot-rolled coils, and roll hard-rolled plates with a thickness of 0.2-0.45mm through the hard-rolling unit. When rolling back and forth in a single group of rolling mills, the surface will be pulled out of the drawing pattern, and the tinned line on the hard-drawn coil will be tinned on both sides. The drawing pattern on the surface of the board is more beautiful, and at the same time, the oxidation resistance and environmental protection of the product are improved. The tinned coil material is subjected to three pre-treatments to clean the surface stains. Hot air blowing and drying, after drying, enter the chemical coating room to coat double-sided chromium-free passivation solution, the passivation solution adopts chromium-free formula, which is environmentally friendly and increases the anti-oxidation and corrosion resistance, and can also increase the adhesion of the color varnish. The thickness of the chrome-free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com