Control method for preventing trip accident caused by steam turbine steam-flow excited vibration

A technology of steam flow excitation and control method, applied in the directions of machines/engines, mechanical equipment, engine components, etc., can solve the problems of unpredictability, threats to the safety and economic operation of the unit, large vibration and tripping, and avoid tripping. Accidents, suppression of airflow excitation, and effects of reducing boiler load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

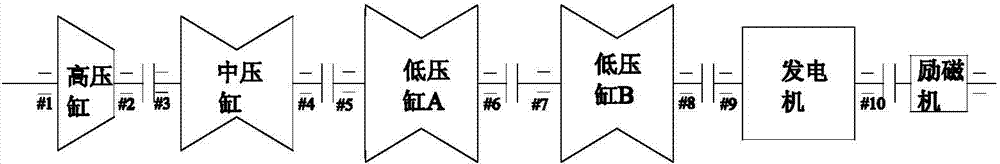

[0017] Please refer to the attached picture, the unit #1 of a certain power plant uses Dongqi’s first self-innovated impulse condensing steam turbine N1030-24.36 / 600 / 600. The shaft system of the unit is composed of high-pressure rotor, medium-pressure rotor, A low-pressure rotor, B low-voltage rotor, and generator rotor. Each rotor is supported by two bearings, which are numbered from 1 to 10 from the turbine end to the motor end. Each rotor is rigidly connected to the wheels, the thrust bearing is between the No. 2 and No. 3 bearings, and the working surface is on the generator side. Among them, No. 1, 2, 3, and 4 bearings are tilting pad bearings, each with six tilting pads, No. 5, 6, 7, and 8 bearings are cylinder-type elliptical bearings, and No. 9 and 10 bearings are end-cap-type elliptical bearings. bearings.

[0018] The unit vibration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| M value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com