Combustion chamber gasket seal for combustion engines of vehicles, preferably of motor vehicles

A technology for combustion chambers and seals, applied in engine seals, engine seals, machines/engines, etc., can solve problems such as high scrap rate and achieve reliable sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

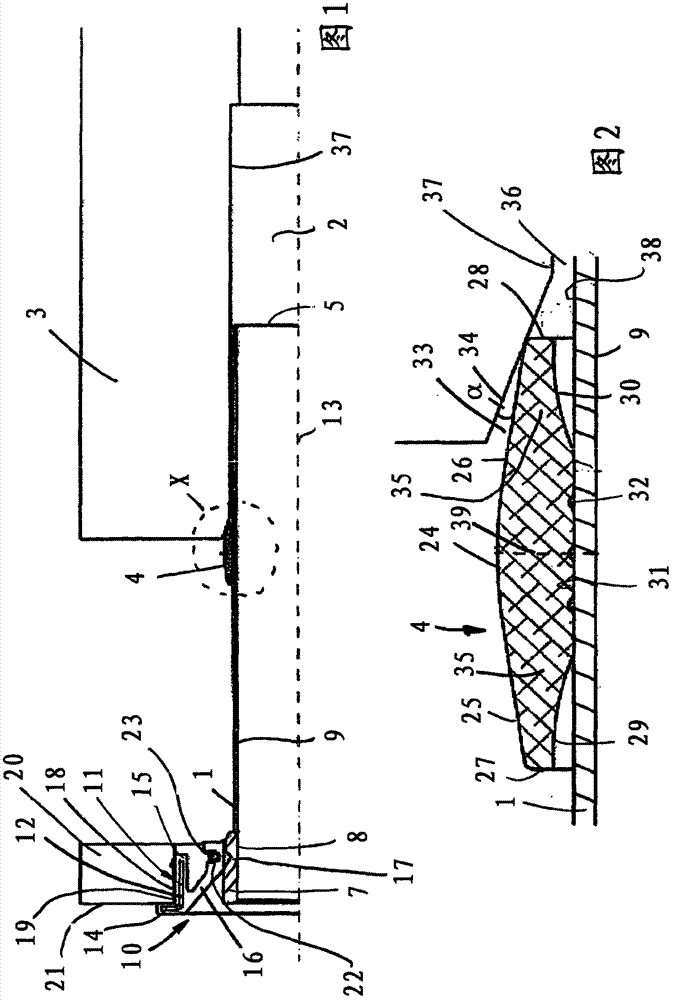

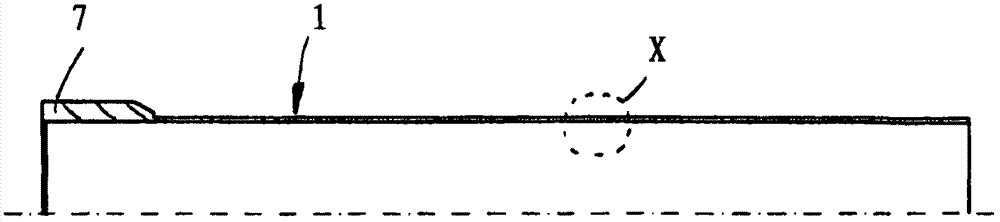

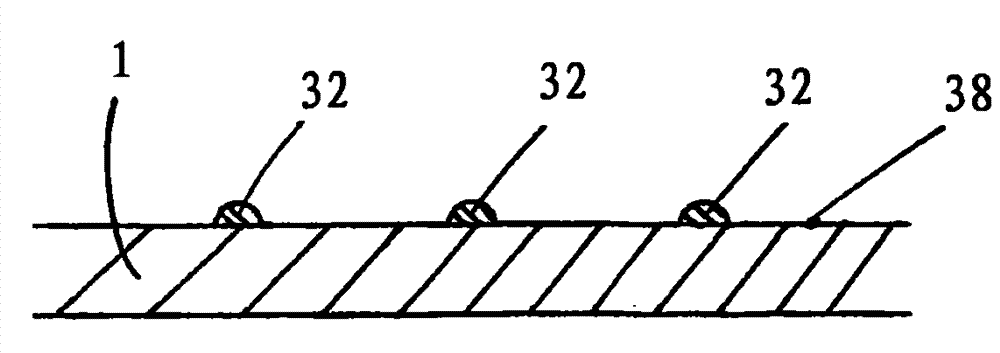

[0027] Combustion chamber seals are used in internal combustion engines of vehicles, in particular motor vehicles. The combustion chamber seal has an injector sleeve 1 which is inserted with one end into a combustion chamber 2 of a cylinder head 3 . The elastically deformable sealing ring 4 in the mounted position serves to seal the injector sleeve 1 in the combustion chamber 2 . The injector sleeve 1 is made, for example, of high-grade steel, preferably stainless steel, but can also be made of other suitable materials, such as ceramic materials, other metallic materials or the like.

[0028] The outer diameter of the injector sleeve 1 is slightly smaller than the diameter of the combustion chamber 2 . The narrow annular gap thus formed is sealed by the elastically deformable sealing ring 4 in the installed position.

[0029] At the end of the injector sleeve 1 protruding from the combustion chamber 2 there is a reinforcing ring 7 whose cylindrical inner side 8 forms a conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com