Digital pilot-operated cartridge overflow valve

A cartridge overflow valve, digital technology, applied in the field of pressure valves, can solve the problems of inaccurate set pressure, potential safety hazards, and different levels, so as to achieve accurate overflow and more flexibility in system design and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

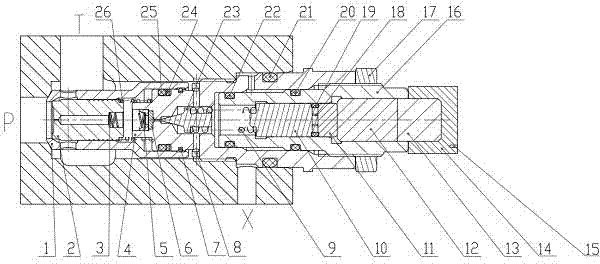

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, a digital pilot cartridge overflow valve includes a communication interface 15, which is connected to a numeric keyboard or set the overflow pressure through remote programming. The communication interface 15 is installed on a display screen 14, and the display screen 14 It can display the set overflow pressure and be fixed on the controller 13 through the slot. The controller 13 is connected to the D / A module 12 through a slot, and the D / A module 12 is connected to the proportional amplifier 11 through a wire; Contact with pilot spool spring 9. The controller 13 reads the set pressure value, converts the digital signal into an analog signal through the D / A module 12, and the analog signal passes through the proportional amplifier 11 and drives the electromagnet 10 through the socket 18 to generate an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com