A kind of embroidered variable-diameter rubber hose

A technology for rubber hoses and rubber pipes, applied in the direction of pipe connection layout, pipe/pipe joints/pipe fittings, passing elements, etc., can solve problems such as difficult connection into pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

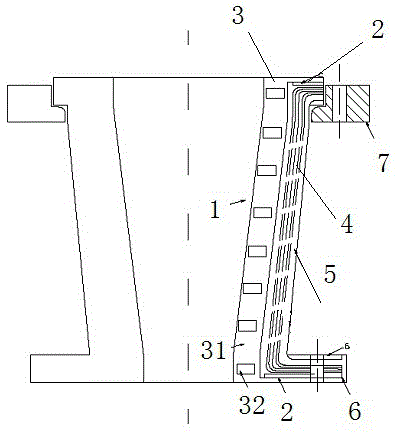

[0012] A collar-reduced rubber hose, see figure 1 , which includes a rubber pipe 1 and flanges 2 arranged at both ends of the rubber pipe. The rubber pipe 1 includes an inner lining layer 3 , a reinforcing layer 4 and an outer covering layer 5 from the inside to the outside. The inner liner is laid on the entire pipeline including the connector part. Rubber hose inner lining layer 3, rubber material of outer coating layer 5 and fiber material of reinforcement layer 4 extend along the circumferential direction and vertical direction at both ends of the rubber hose, and form flange 2 together with several ring-shaped metal sheets 6, one end method The flange has a rotatable flange 7. The lining layer 3 contains a plurality of wear-resistant rings 32 made of alloy steel embedded in the rubber material 31 .

[0013] The lumen of the invention increases or decreases from one end to the other end, and is tapered. The wear-resistant ring made of alloy steel buried in the inner li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com