A liquid chromatograph capable of controlling the mixing ratio of mobile phase

A technology of liquid chromatograph and mixing ratio, which is applied in the field of liquid chromatograph, can solve the problems of mixing ratio deviation of mixed liquid, deviation of different mixing ratio, lack of liquid chromatograph, etc., and achieve easy operation, high accuracy, The effect of simplifying the calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A preferred embodiment of the present invention will be introduced below in conjunction with the accompanying drawings.

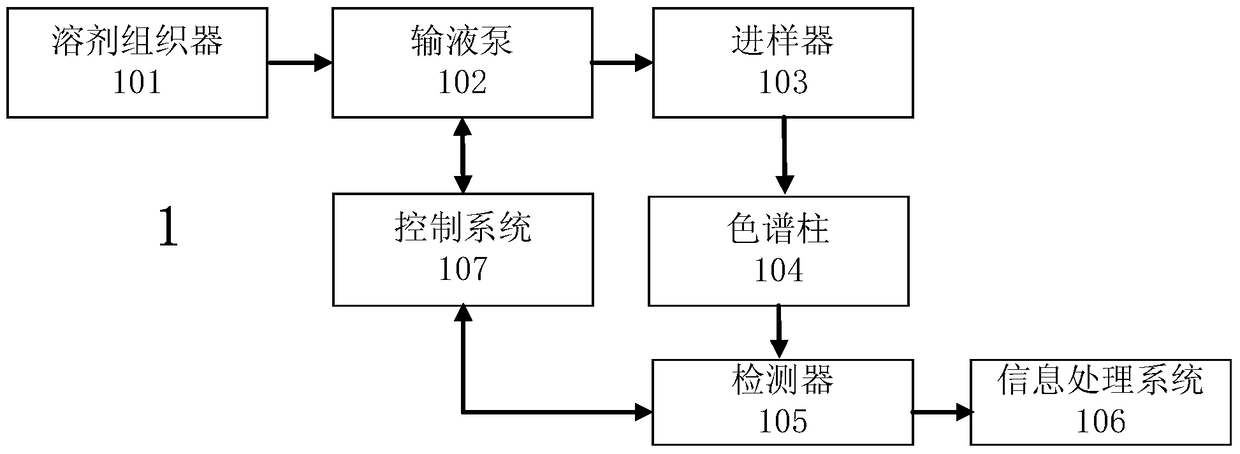

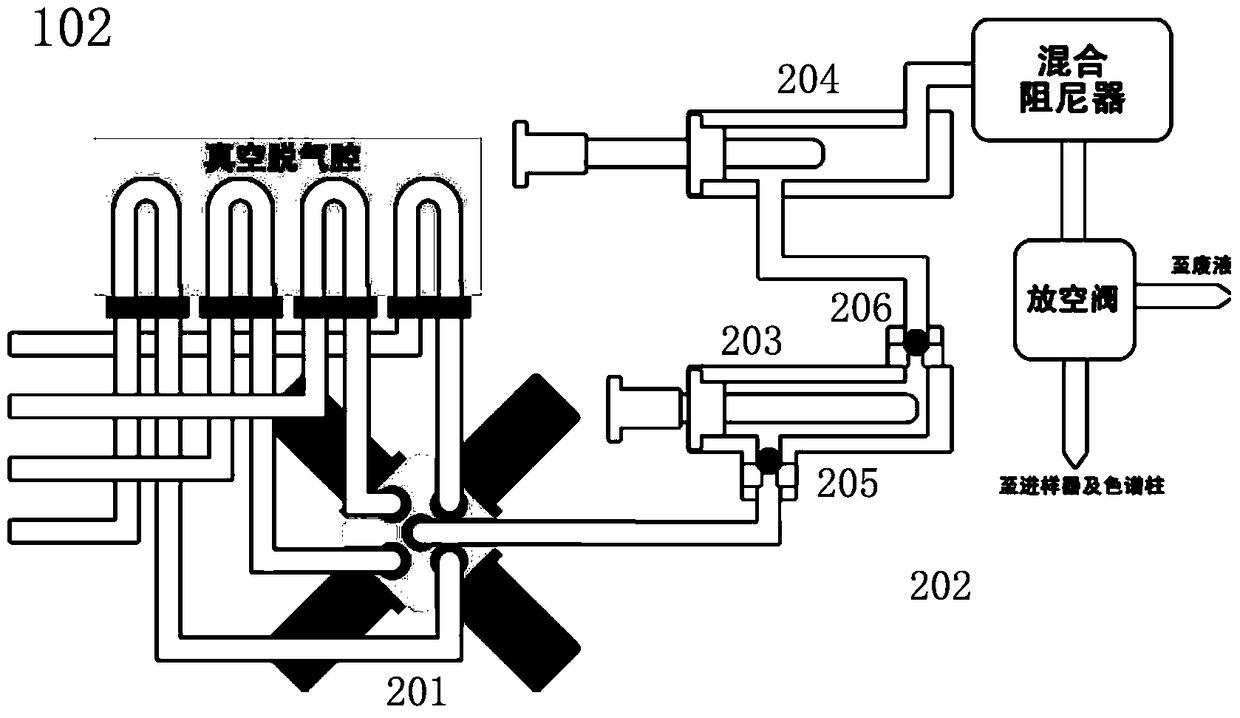

[0032] refer to figure 1, the liquid chromatograph 1 in this embodiment includes a solution organizer 101, an infusion pump 102, a sampler 103, a chromatographic column 104, a detector 105, an information processing system 106, a control system 107, etc., wherein the solution organizer 101 After degassing, the solution is injected into the system of the liquid chromatograph 1 by the infusion pump 102 as the mobile phase, the sample solution is injected into the mobile phase through the injector 103, and is loaded into the chromatographic column 104 (stationary phase) by the mobile phase Because each component in the sample solution and the chromatographic column have different polarities, when the sample solution runs relatively in the chromatographic column 104, through repeated adsorption-desorption distribution processes, each component has a diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com