Form rolling apparatus and form rolling method

A technology of forming rolling and equipment, which is applied in metal rolling, other household utensils, household utensils, etc., can solve problems such as insufficient and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] One embodiment of a shape rolling apparatus and a shape rolling method will be explained below with reference to the description of the accompanying drawings.

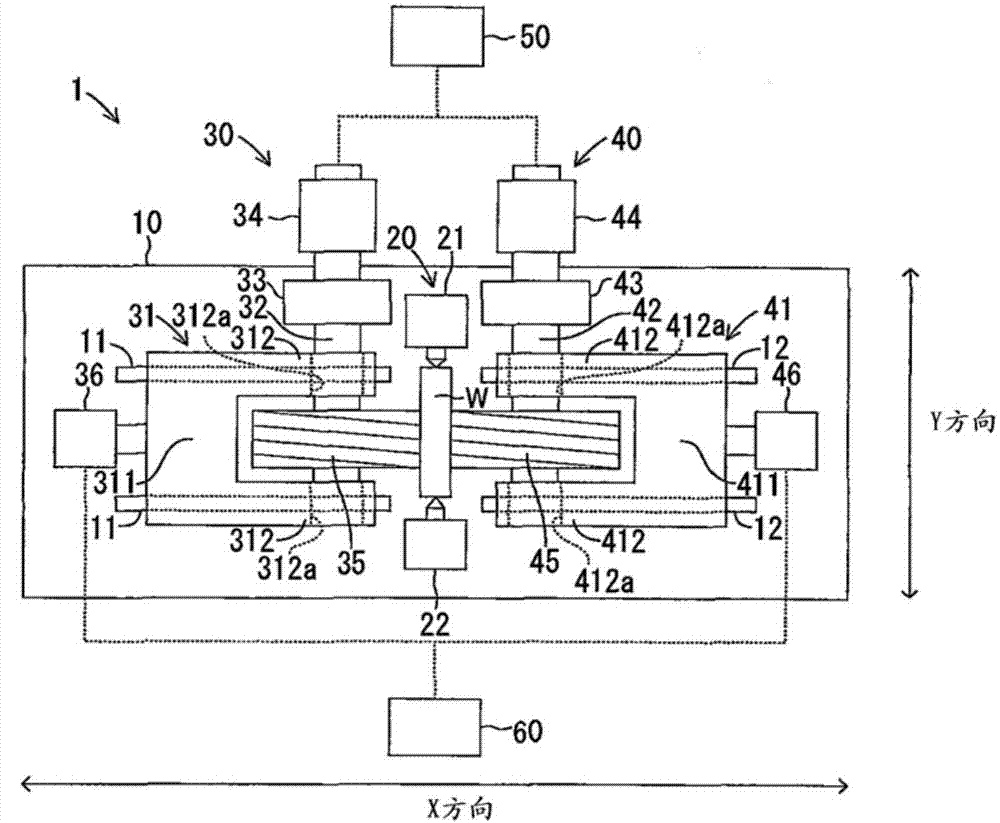

[0036] Such as figure 1 As shown in , the forming rolling apparatus 1 includes a base plate 10 , a support portion 20 , a first die unit 30 , a second die unit 40 , a rotation control device 50 and a position control device 60 .

[0037] Such as figure 1 As shown in , the substrate 10 is formed in a substantially rectangular shape in plan view. For purposes of explanation, the longitudinal direction of the substrate 10 (ie, figure 1 The left and right directions in the) are defined along the X direction, and the direction orthogonal to the X direction ( figure 1 The up and down direction in the ) is defined as the Y direction. The direction orthogonal to the X direction and the Y direction is the up and down direction.

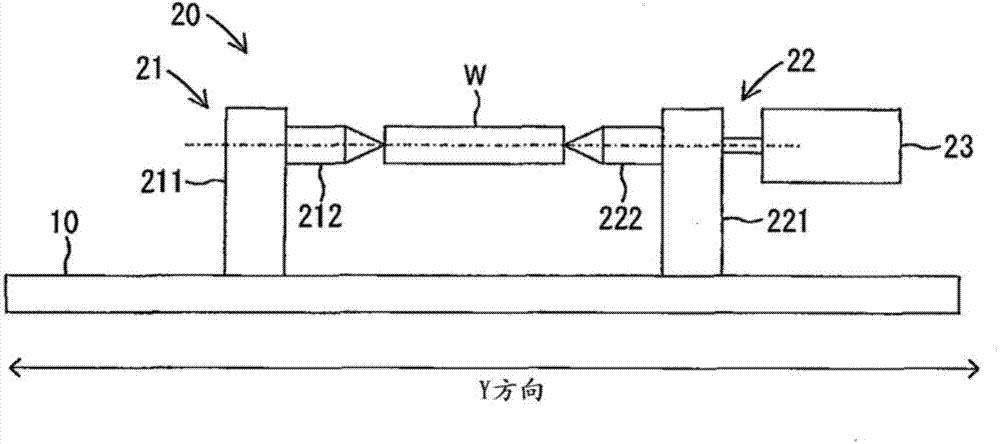

[0038] The support portion 20 is provided on the substrate 10 . The supporting part 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com