In-die tapping machine with excessive torque failure device

An in-mold tapping machine and over-torque technology, applied in thread cutting devices, thread cutting machines, metal processing equipment, etc., can solve problems such as tap breakage, equipment damage, lack of preventive functions and preventive structures, etc., to ensure safety and high efficiency The effect of using the request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

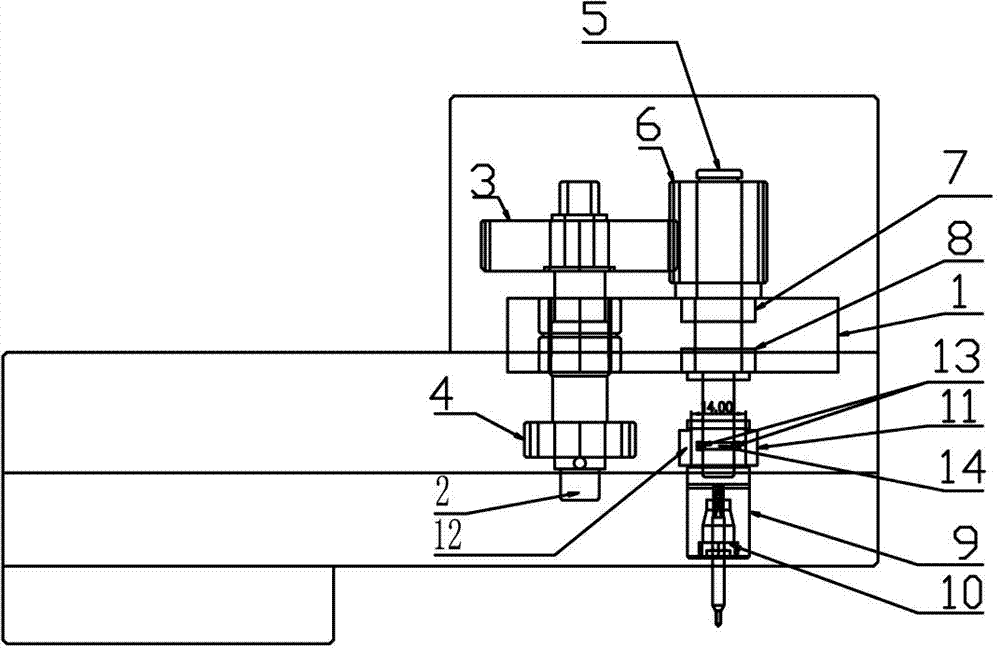

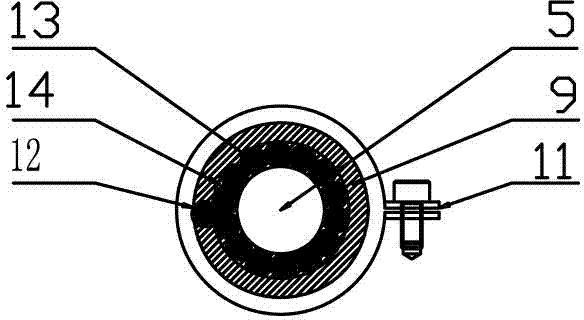

[0012] The size of the moving block 1 is 100mm*60mm*20mm, the size of the transmission shaft 2 is ?20mm*120mm, the data index of the transmission gear 3 is m=1, z=46, and the data index of the first stage transmission gear 4 is m=1.5 , z=17, the size of the main shaft 5 is (?12mm*80mm, the data index of the driven wheel is 6m=1, z=23, the product model of the upper bearing 7 is 698), the product model of the lower bearing 8 is 698 , the size of the tap spindle 9 is ?16mm*44mm, the size of the tap spindle is ?16mm*44m, the size of the locking mechanism 10 is ?9mm*20mm, the size of the torque failure device 11 is m5 cup head screw, and the friction adjustment ring The size of 12 is ?14mm*20mm*10mm), the size of ball 13 is ?2mm, the size of retaining groove 14 is R1mm, the size of T plate 15 is 100mm*92mm*20mm, and the size of lower plate 16 is 250mm*92mm*30mm , the size of the middle plate 17 is 250mm*92mm*30mm, the size of the upper plate 18 is 120mm*92mm*50mm, and the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com