Die internally provided with free-shaped water way and manufacturing method of die

A production method and waterway technology, applied in mold making, molds with conformal waterways inside, can solve the problems of long cooling time, large residual stress, warping and deformation, etc., and achieve consistent cooling speed, good appearance and uniform cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

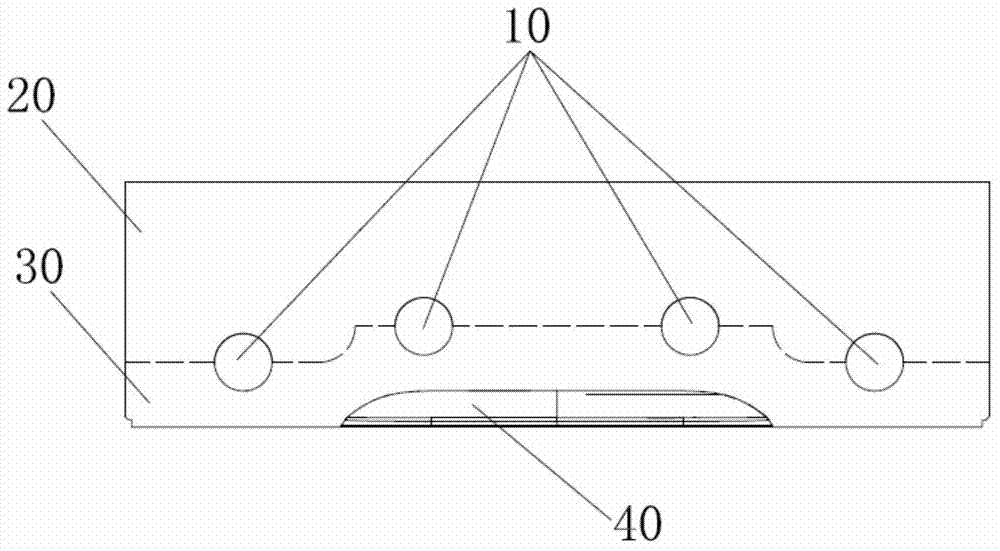

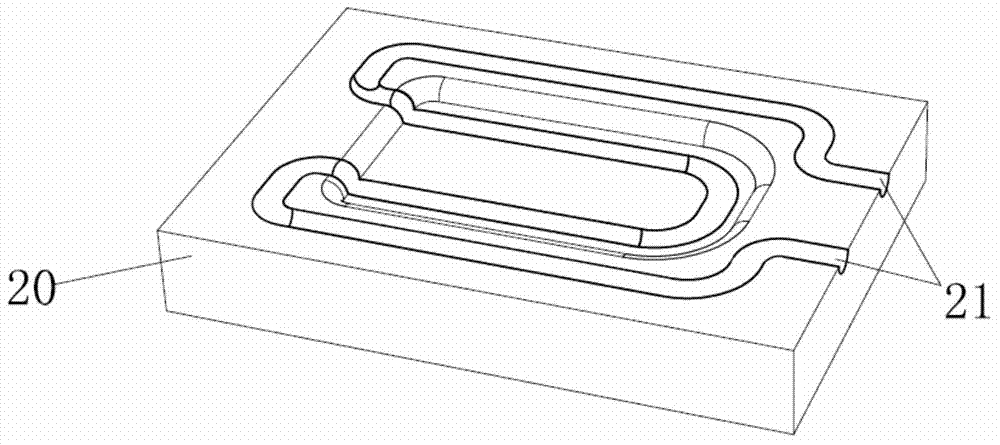

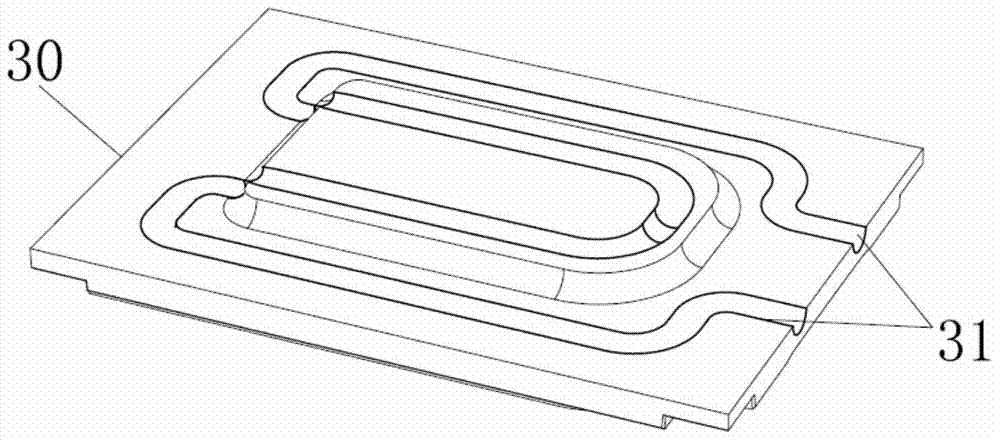

[0027] The specific embodiment of the present invention provides a method for making a mold with a conformal waterway inside. The mold has a cavity 40 and a mold core. The method includes a mold core manufacturing step. When making the mold core, according to the computer 3D model, Shaped waterway 10 is the boundary ( figure 1 and Figure 8 The dotted line in the middle represents the boundary, not the real gap inside the mold core) Divides the mold core into figure 2 The upper die shown is 20 and image 3 Lower die core 30 as shown, such as figure 1 and image 3 As shown, the lower mold core 30 has a water track 31 that matches the conformal waterway 10, and the upper mold core 20 and the lower mold core 30 can also have a matching upper half and a lower half of the conformal waterway 10 at the same time. Waterway trajectories21,31. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com