Carving tool bit of carving machine

A technology of engraving knives and engraving machines, which is applied in the field of engraving knife heads, can solve problems such as low production efficiency, time-consuming and laborious, and extensive control methods, and achieve the effect of accurate engraving, precision assurance, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

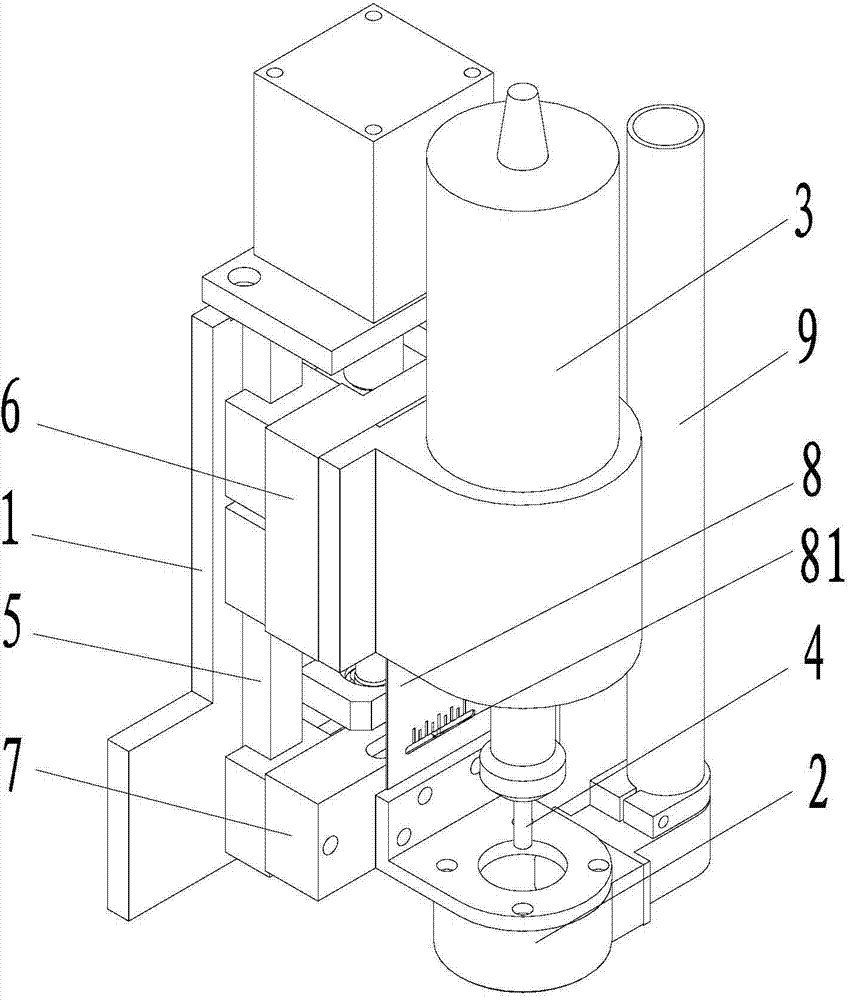

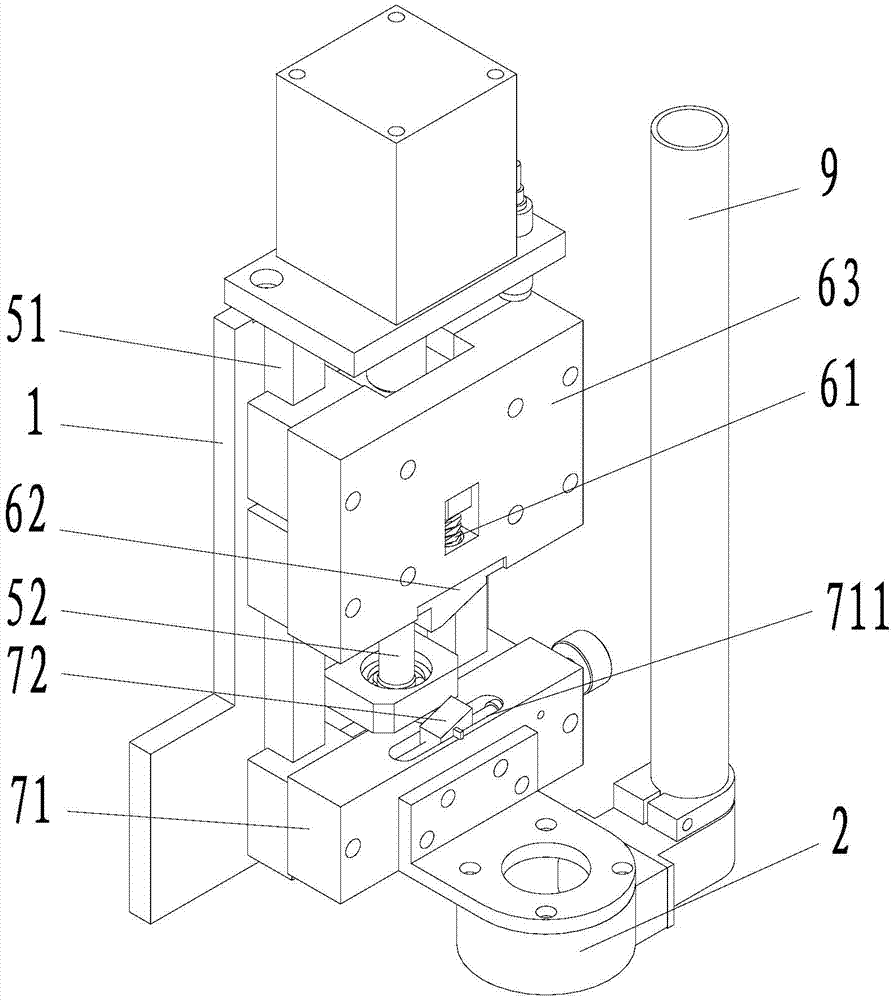

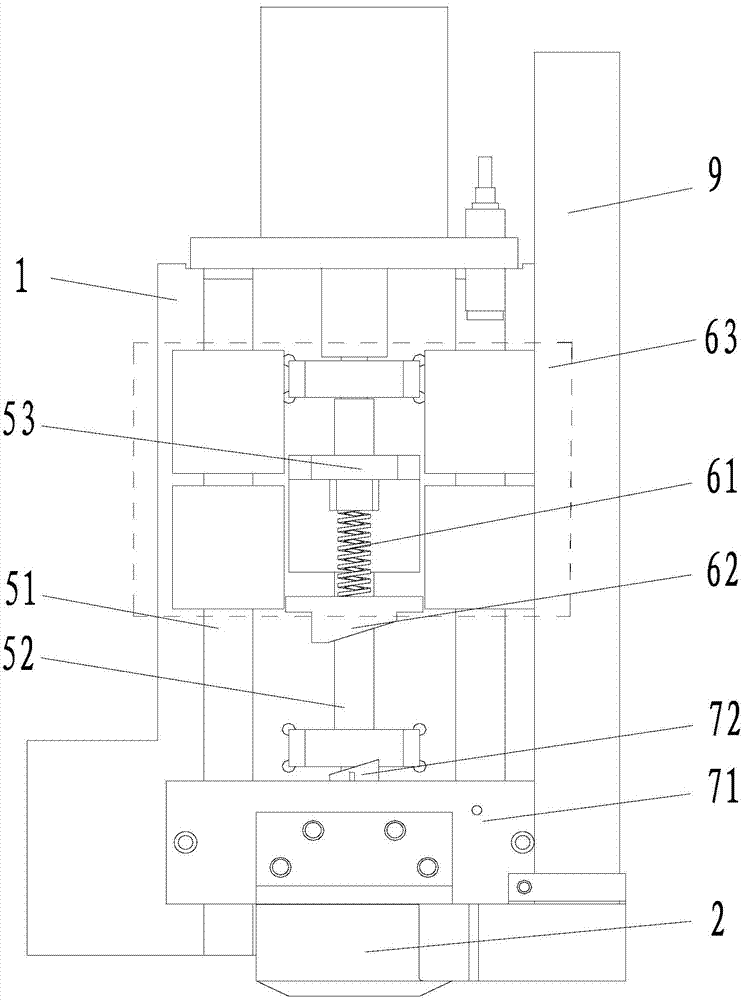

[0022] A kind of engraving head of engraving machine of the present embodiment has such as Figure 1~3 The shown structure comprises a fixed plate 1, a limiting disc 2, a tool seat 3, and a milling cutter 4 arranged on the tool seat 3. The limiting disc 2 is provided with a through hole for the milling cutter 4 to pass through. It includes a longitudinal guide rail 5 arranged on the fixed plate 1, an upper linear motion mechanism 6 and a lower linear motion mechanism 7 arranged on the longitudinal guide rail 5, the upper linear motion mechanism 6 is fixedly connected with the tool holder 3, and the lower linear motion mechanism The mechanism 7 is fixedly connected with the limit plate 2, wherein:

[0023] The longitudinal guide rail 5 includes a longitudinal sliding guide rail 51 and a longitudinal driving guide rail 52 parallel to each other, and a driving block 53 is arranged on the longitudinal driving guide rail 52;

[0024] The upper linear motion mechanism 6 includes a ...

Embodiment 2

[0033] A kind of engraving head of engraving machine of the present embodiment has such as Figure 4 In the above structure, a base 11 extends forward from the bottom end of the fixed plate 1, and the lower linear motion mechanism 7 also includes a longitudinally telescopic lower spring, and the lower end of the lower spring is fixed on the base 11, Its upper end is fixedly connected with the lower surface of the lower connector 71, but the connection mode between the upper end of the lower spring and the lower surface of the lower connector 71 is not limited to this, for example, the two are in contact with each other, but not fixedly connected, etc., also belong to the present invention Protection range; the compression spring force value of the upper spring is greater than the compression spring force value of the lower spring; the function of the lower spring is to provide double buffer protection for the fitting of the limit plate 2, so as to ensure that the limit plate 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap