Novel air chamber base plate

A backing plate and air chamber technology, which is applied in the field of auto parts, can solve problems such as uneven height, deformation of the backing plate of the air chamber, unevenness of the backing plate of the air chamber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

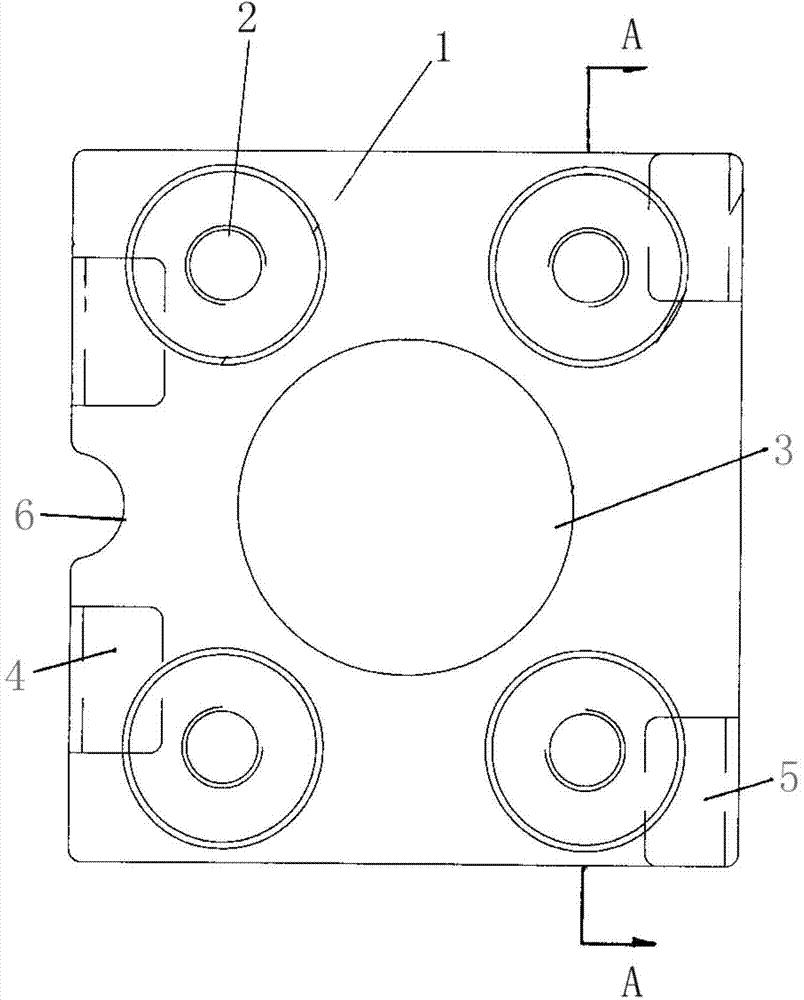

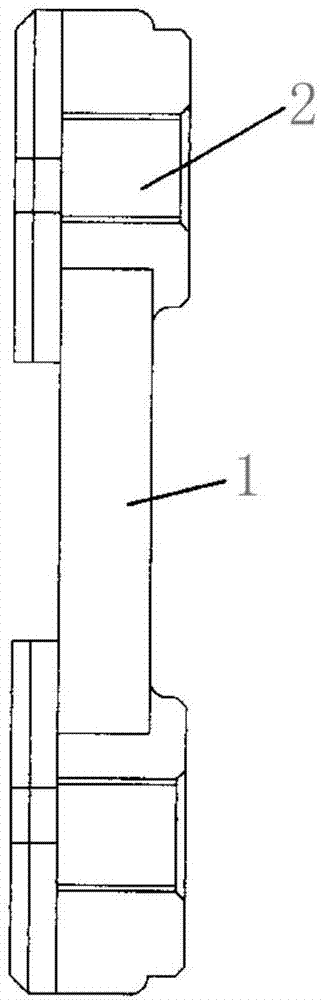

[0010] like figure 1 , 2 As shown, the present invention is respectively provided with bracket threaded holes 2 at the four corners of the square backing plate 1, and the round hole 3 of the reinforcement welding process is arranged at the middle part of the square backing plate 1, and front ends are respectively provided on both sides of the square backing plate 1. Welding claws 4 and rear end welding claws 5 and the reserved welding hole 6 are arranged at the middle part of one side of the square backing plate 1 . Through the above settings, the present invention is limited on the upper plane of the automobile rear axle housing by the front end welding claw 4 and the rear end welding claw 5, and the inner edge of the round hole 3 of the strengthening welding process is carried out with the upper plane of the automobile rear axle housing. Welding connection, the reserved welding port 6 is welded and fixed to one side of the rear axle housing of the automobile, which avoids t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com