Automatic train turn-back control method and system

A technology for automatic protection of trains and trains, which is applied to the control system of the transportation center, transportation and packaging, railway car body parts, etc., which can solve the problems of long train communication establishment time and low success rate of return, so as to avoid excessive establishment time Long, the effect of improving the return efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

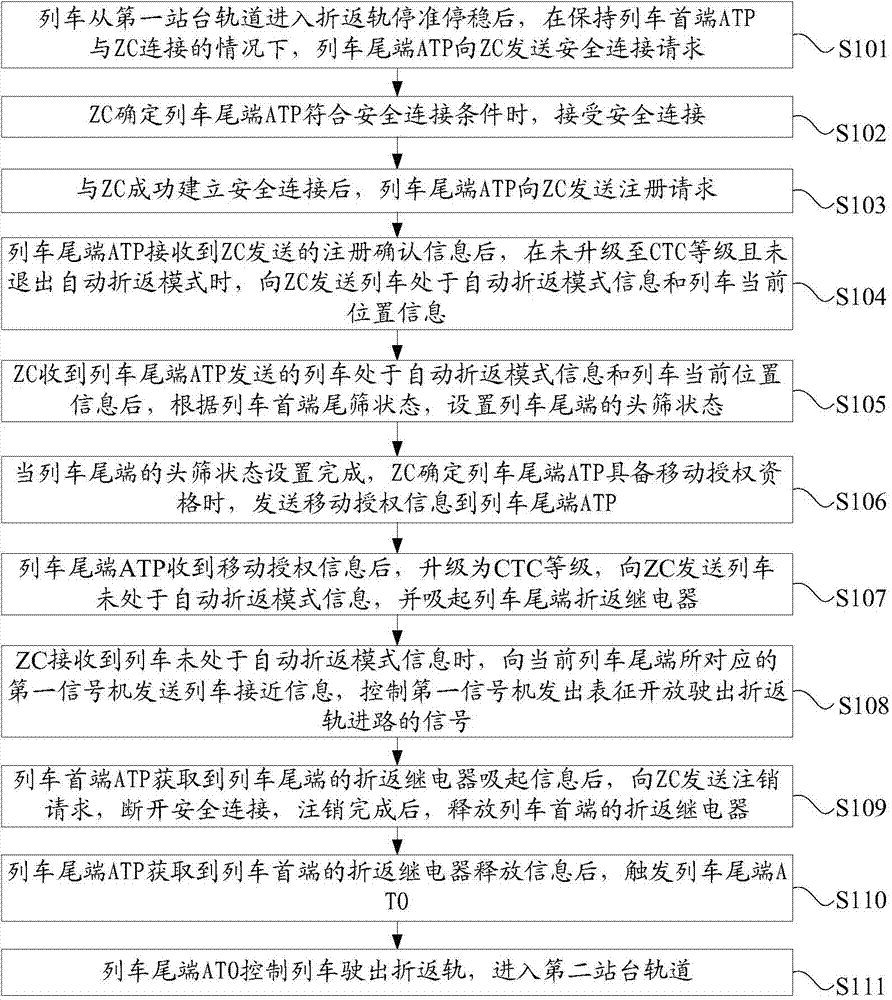

[0060] see figure 1 , figure 1 It is a flow chart of a control method for automatic train turning back provided by an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0061] Step S101, after the train enters the turn-back track from the first platform track and comes to an accurate stop, while maintaining the connection between the ATP (Automatic Train Protection, automatic train protection system) at the head end of the train and the ZC (Zone Controller, zone controller), the train The tail ATP sends a secure connection request to the ZC;

[0062] Specifically, the ATP at the head end of the train and the ATP at the tail end of the train use different identification numbers. The ZC is set at the position of the ground station and belongs to the ground signal equipment.

[0063] Step S102, when the ZC determines that the ATP at the end of the train meets the safety connection conditions, accept the safety connection;

[0064] Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com