Process method for collecting dust and recycling oil from pyrolyzed high-temperature oil gas

A process method and oil recovery technology, applied in gas dust removal, petroleum industry, separation methods, etc., can solve problems such as complex process, single dust removal method, and difficulty in industrialization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

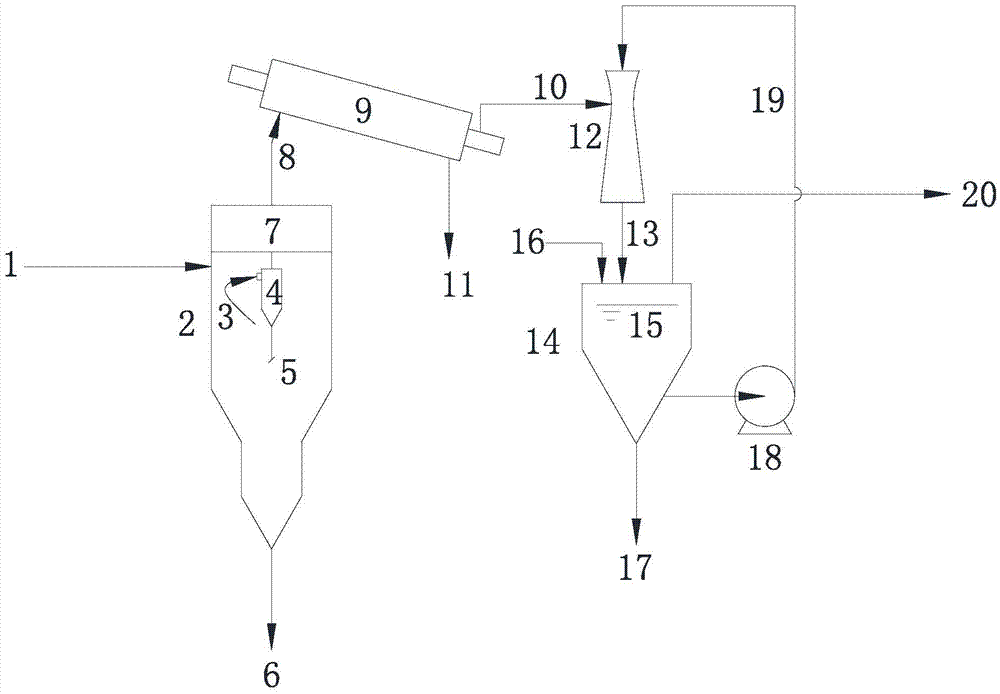

[0029] A process for pyrolyzing high-temperature oil and gas to remove dust and recover oil, comprising the following steps: 1) 750°C high-temperature pyrolysis gas 1 from a dual-fluidized bed pyrolysis device, and gas from the parent cyclone cylinder 2 of the parent-child cyclone dust removal device The inlet enters tangentially, and after capturing dust particles above 15 microns, the purified gas 3 of the parent cyclone whose temperature drops to 720°C is obtained; the collected dust falls to the cone extension section of the parent cyclone cylinder 2 and is stored The particles 6 are discharged through the pipe.

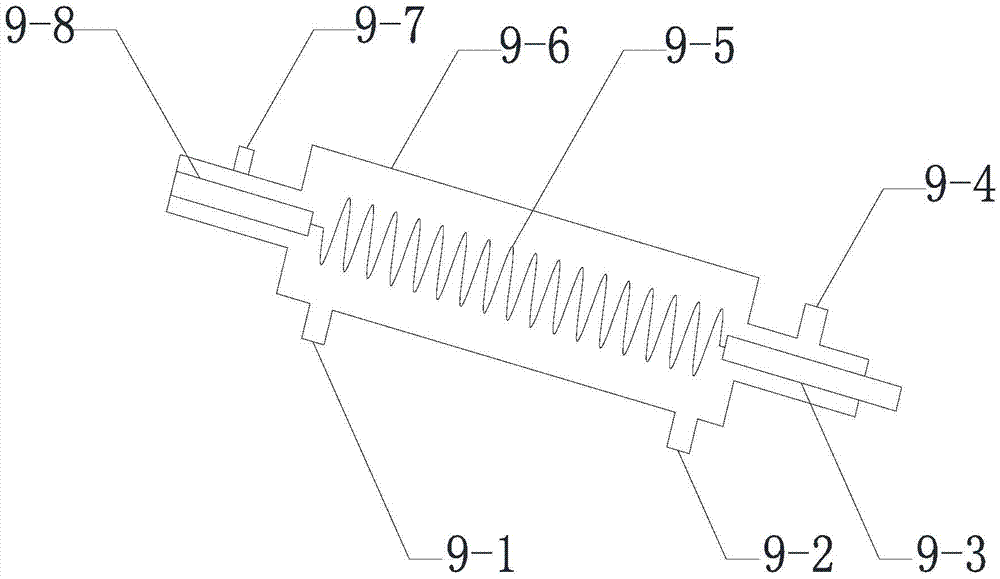

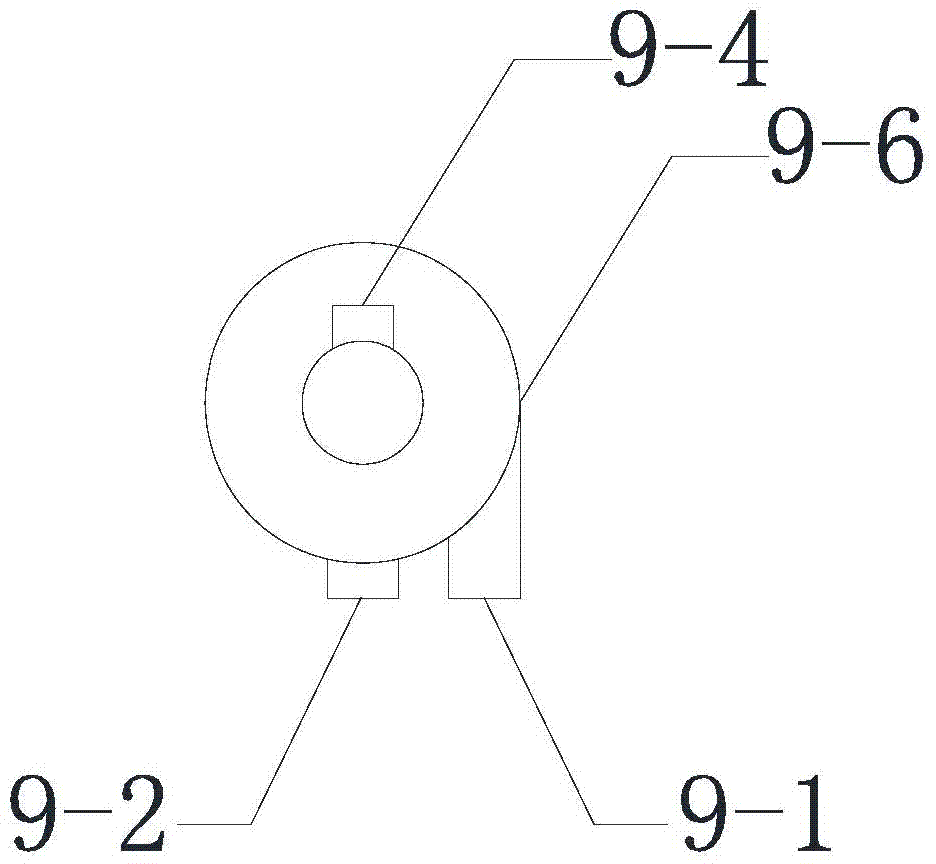

[0030] 2) The purified gas 3 of the parent cyclone with a temperature of 720°C directly enters the multi-pipe cyclone separator 4 inside the mother cyclone cylinder 2, and after trapping particles between 5-15 microns, the temperature drops to 710°C. The multi-pipe cyclone purified gas 8, the multi-pipe cyclone purified gas 8 is sent out after being merged in the...

Embodiment 2

[0034] A process for recovering oil by pyrolysis of high-temperature oil gas dedusting, comprising the following steps:

[0035] 1. The 680°C high-temperature pyrolysis gas 1 from the dual-fluidized bed pyrolysis device enters tangentially from the gas inlet of the parent cyclone cylinder 2 of the parent-child cyclone dedusting device, and is purified after collecting dust particles above 15 microns The final parent cyclone purifies the gas 3. Due to the heat dissipation effect of the parent cyclone cylinder body 2, the temperature of the parent cyclone purified gas 3 drops to 610°C. The dust particles 6 collected and dropped to the conical extension section of the parent cyclone cylinder body 2 are discharged through the pipeline.

[0036] 2. The purified gas 3 of the parent cyclone at a temperature of 610°C directly enters the multi-tube cyclone separator 4 inside the parent cyclone cylinder 2, and after capturing particles between 5 and 15 microns, it is purified by a multi-...

Embodiment 3

[0040] The 650°C high-temperature pyrolysis gas 1 from the dual fluidized bed pyrolysis device enters tangentially from the gas inlet of the parent cyclone cylinder 2 of the parent-child cyclone dedusting device, and after collecting dust particles above 15 microns, the purified gas is obtained Parent cyclone purifying gas 3. Due to the heat dissipation effect of the parent cyclone cylinder body 2, the temperature of the parent cyclone purified gas 3 drops to 618°C. The collected dust particles 6 fall to the conical extension section of the parent cyclone cylinder 2 for storage and then are discharged through the pipeline. The purified gas 3 of the parent cyclone with a temperature of 618°C directly enters the multi-tube cyclone separator 4 inside the parent cyclone cylinder 2, and after trapping the particles between 5-15 microns, the purified gas 8 of the multi-tube cyclone with a temperature of 603°C It is sent out after being merged in the collecting pipe box 7. The coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com