Automatic rock debris dredging and washing device

A cuttings and automatic technology, applied in the field of automatic cuttings fishing and washing device, can solve the problems of prone to error and harsh working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

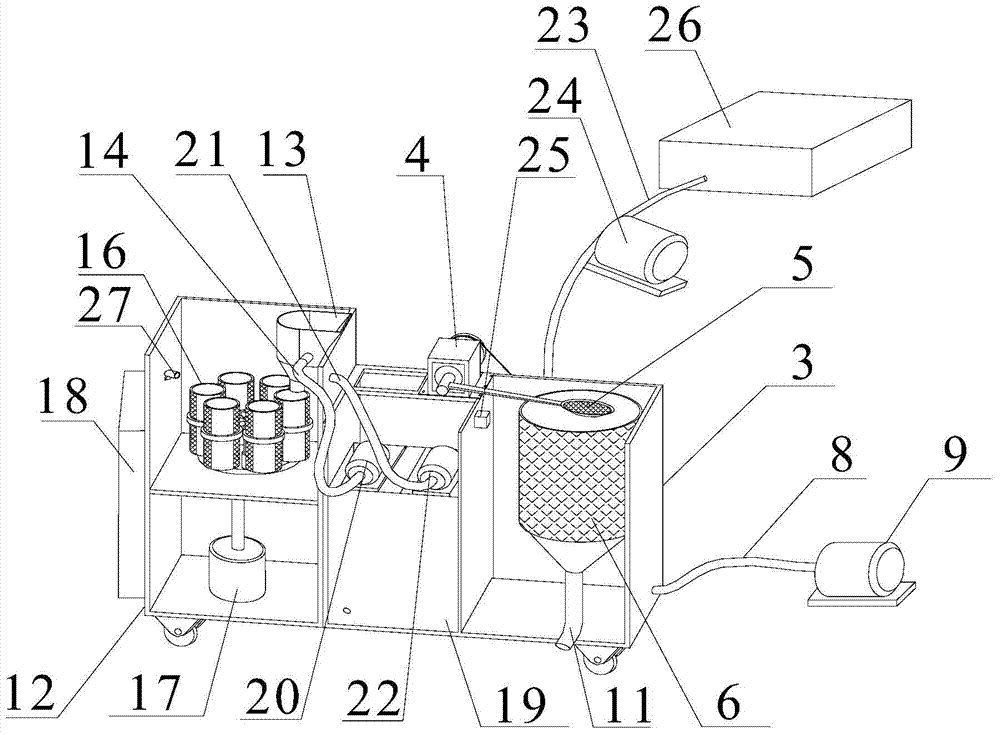

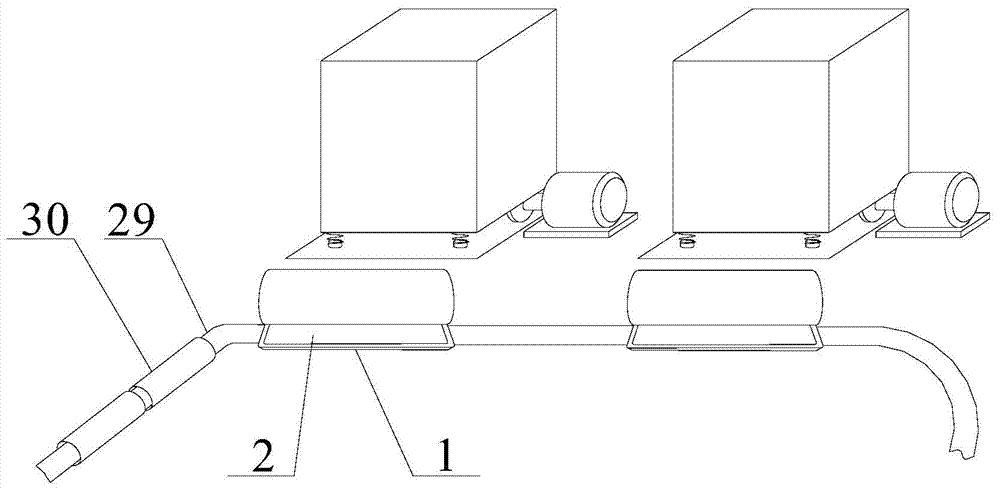

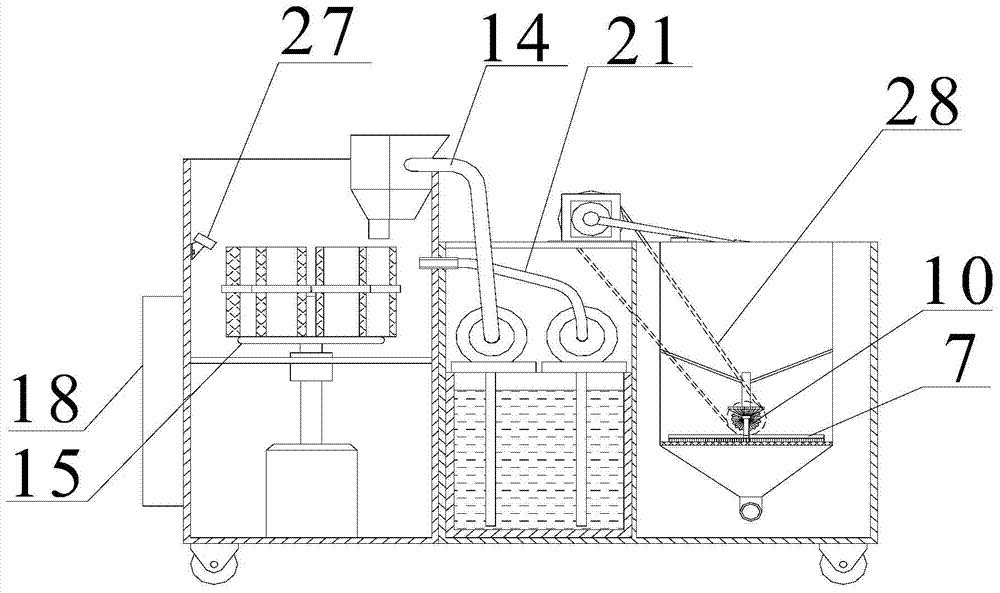

[0045] figure 1It is a schematic diagram of the structure of the circulating water tank 3 and the collecting water tank 12 of an automatic cuttings fishing and washing device provided by the embodiment of the present invention; figure 2 It is a schematic structural diagram of the sand receiver 1 of an automatic cuttings fishing and washing device provided by the embodiment of the present invention; image 3 It is a front view of the circulating water tank 3 and the collecting water tank 12 of an automatic debris washing device provided by the embodiment of the present invention; Figure 4 A top view of the circulating water tank 3 and the collecting water tank 12 of an automatic rock cuttings fishing and washing device provided by the embodiment of the present invention; Figure 1-4 As shown, an automatic debris washing device provided in this embodiment includes a collection device, a filter device, a collection device and a control device;

[0046] The collection device i...

Embodiment 2

[0056] figure 1 It is a schematic diagram of the structure of the circulating water tank 3 and the collecting water tank 12 of an automatic cuttings fishing and washing device provided by the embodiment of the present invention; figure 2 It is a schematic structural diagram of the sand receiver 1 of an automatic cuttings fishing and washing device provided by the embodiment of the present invention; image 3 It is a front view of the circulating water tank 3 and the collecting water tank 12 of an automatic debris washing device provided by the embodiment of the present invention; Figure 4 A top view of the circulating water tank 3 and the collecting water tank 12 of an automatic rock cuttings fishing and washing device provided by the embodiment of the present invention; Figure 1-4 As shown, an automatic debris washing device provided in this embodiment includes a collection device, a filter device, a collection device and a control device;

[0057] The collection device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com