Knitted rubber hose

A braided hose and hose technology, used in hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of high cost of chemical corrosion resistant pipes, equipment loss, easy aging, etc., and achieve easy pipe laying and extended use. Longevity and anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

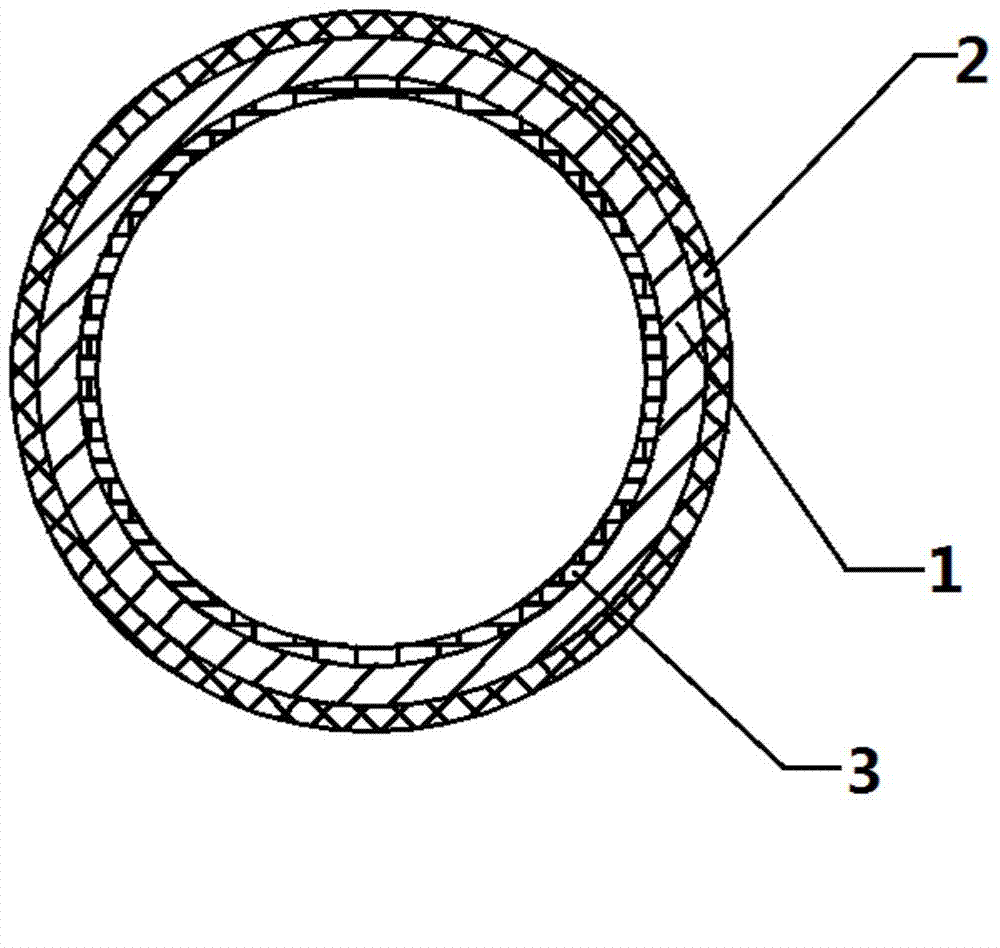

[0010] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0011] A braided rubber hose as shown in the accompanying drawings includes a rubber hose main body 1 , the inner wall of the rubber hose main body 1 is provided with a PU plastic coating; the outer wall of the rubber hose main body 1 is provided with a linen braided layer 2 .

[0012] The hose body 1 is a styrene-butadiene rubber hose.

[0013] The linen braided layer 2 has a mesh structure.

[0014] The hose main body 1 adopts styrene-butadiene rubber hose with low cost but high anti-aging performance. The chemical corrosion resistance of the hose main body 1 is improved through PU plastic coating, which can effectively prolong the service life of the hose. The toughness is improved for the main body 1 of the rubber hose, which is easy to lay the pipeline and is not easy to break.

[0015] An embodiment of the present inventio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap