The box structure of the air handling unit

A technology of air handling unit and box structure, applied in the direction of heating and ventilation hood/cover, etc., can solve the problems of not being able to completely cut off the air inside the box, heat loss, etc., achieve a simple and beautiful appearance, and reduce material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to help those skilled in the art to accurately understand the claimed subject matter of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

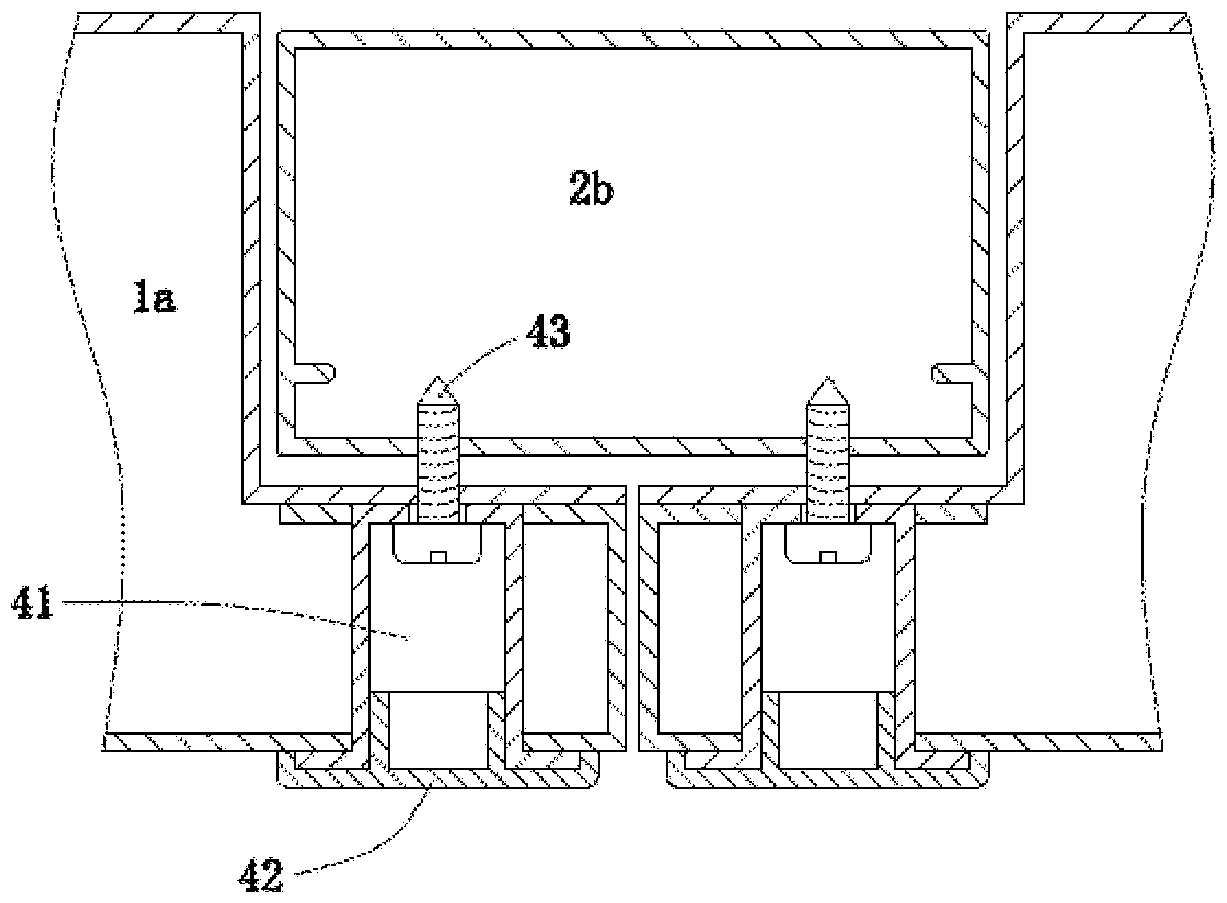

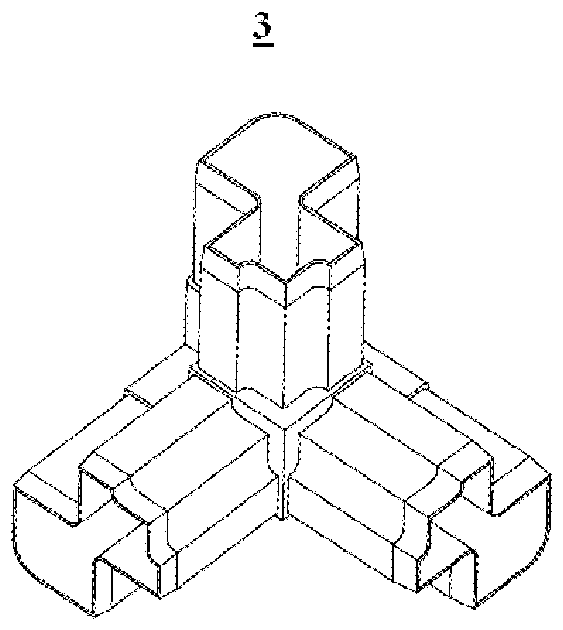

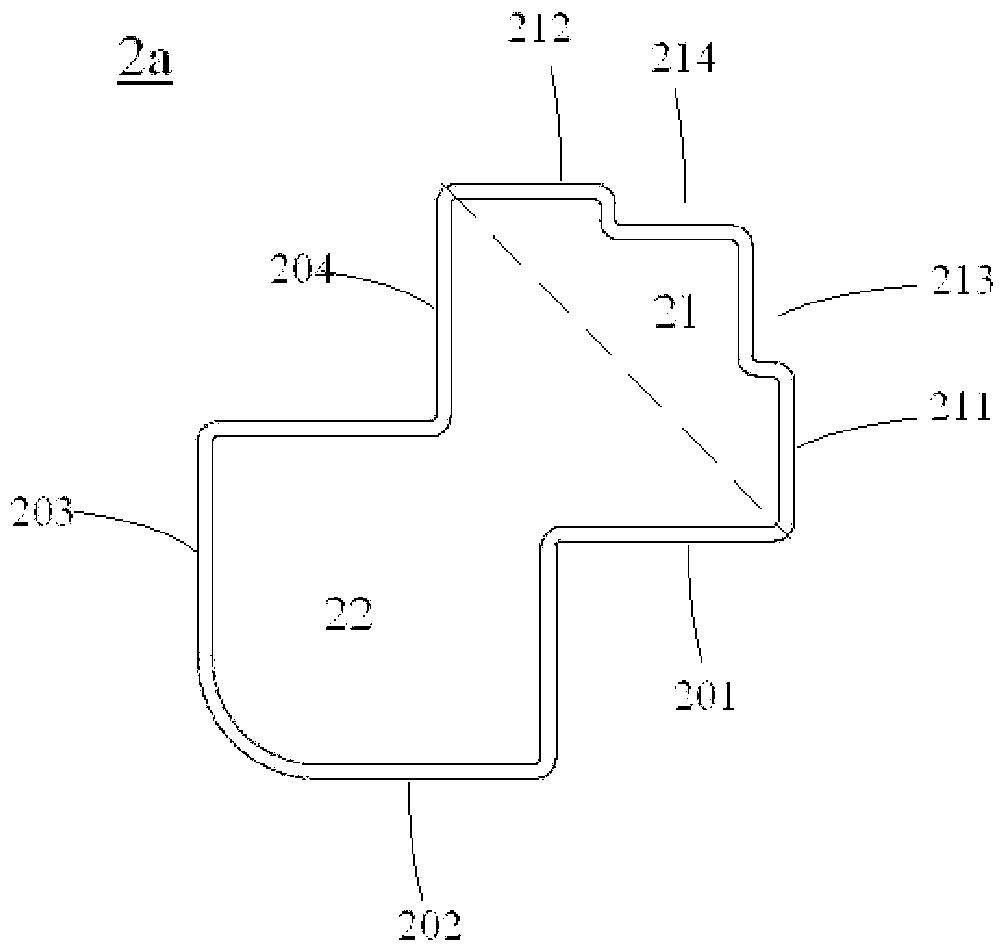

[0033] see figure 2, is a schematic diagram of the box structure of the air handling unit involved in the present invention. It includes a plurality of panels 1, a plurality of frame strips 2, corner joints 3 and fastening devices 4. The multiple panels 1 at least include a top panel 1 arranged on the top, and side panels 1 arranged around the sides and forming the perimeter of the box structure. These panels 1 are designed according to a certain size to constitute the main part of the air handler cabinet structure. by figure 2 Taking the direction shown as an example, the top panel can be a whole piece, the left side panel and the right side panel are also arranged one piece each, and the front side and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com