Low-temperature infrared radiation panel

An infrared radiation plate and infrared radiation technology, applied in the field of infrared radiation application, can solve the problems of inconvenient transportation, loss, slow internal drying, etc., and achieve the effect of reasonable and simple structure design, low production cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

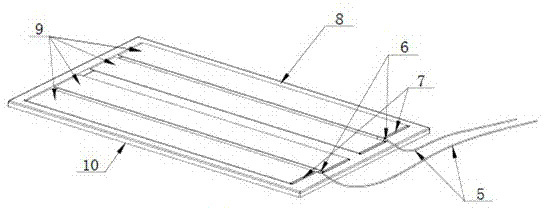

[0047] Preferred embodiment 1: Low temperature infrared radiation panel packaging unit.

[0048] The insulating substrate is made of 200mm×300mm×7mm architectural glazed tiles, the number of low-temperature infrared radiating elements is 1, set in the packaging plastic frame (the plastic frame is made of ordinary temperature-resistant plastic), and the infrared radiation coating is prepared on the ceramic tile The stoneware surface is facing outward, the silver-based electrode, the inorganic electric heating layer and the conductive lead-out are prepared on the bright glaze surface of the ceramic tile facing inward. The conductive lead-out is connected with the power cord, and then 5 mm thick aluminum silicate insulation felt and 1 mm thick The artificial mica board is sealed and fastened with a lock. The electromechanical heating layer is made of graphite powder and fusible amorphous ceramic powder with a thickness of 0.2 mm. The silver-based electrodes and conductive terminals ...

Example Embodiment

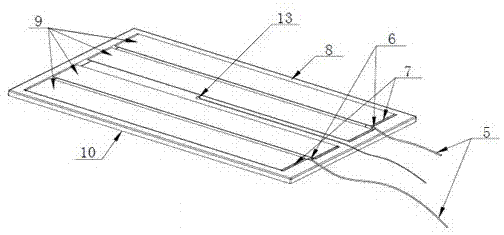

[0049] Preferred embodiment 2: a double-sided heating low-temperature infrared radiation panel packaging unit.

[0050] Using 200mm×300mm×1.2mm artificial mica board as the insulating substrate, the number of low-temperature infrared radiation elements is two, all are set in the packaging plastic frame, the artificial mica board is prepared with the infrared radiation coating side outwards , The other side of the artificial mica board prepared with silver-based electrodes, inorganic electric heating layer and conductive lead-out ends faces inward, and the conductive lead-out ends are all connected to the power cord and fastened with locks. The electromechanical heating layer is made of graphite powder and fusible amorphous ceramic powder with a thickness of 0.3 mm. The silver-based electrodes and conductive terminals are made of silver powder and fusible amorphous ceramic powder. The power density of this embodiment is 0.15 W / cm², and the upper limit of the operating temperature ...

Example Embodiment

[0051] Preferred embodiment 3: Low temperature infrared radiation panel with thermocouple.

[0052] Use 200mm×300mm×5mm tempered glass as the insulating substrate, one side is prepared with infrared radiation coating, and the other side is prepared with silver-based electrode, inorganic heating layer and conductive terminal, in the gap position of the inorganic heating layer , Adopt a bonding process to fix a K-type thermocouple, and the conductive leads are connected to the power cord. The beneficial effect of this embodiment is that the K-type thermocouple is bonded and fixed and cooperated with the K-type temperature control instrument, which can easily realize temperature control and temperature adjustment of the drying equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap