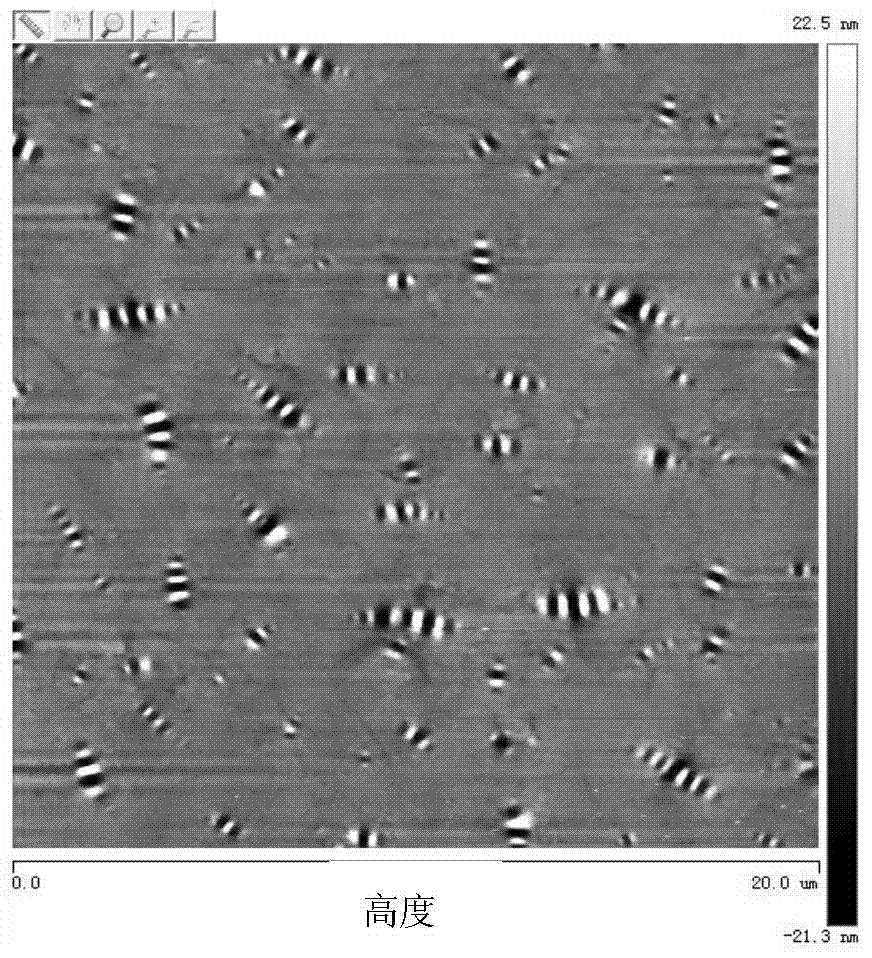

Preparation method and using device thereof for asphalt sample for AFM (Atomic Force Microscopy) observation

A technology for asphalt and to be observed, applied in the direction of scanning probe technology, instruments, etc., can solve the problems that cannot truly reflect the phase structure of asphalt, the film thickness and shape are difficult to effectively control, and the application of atomic force microscopy technology is unfavorable, so as to meet the requirements of observation Demand, anti-aging phenomenon, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Put 200g of the 70# base asphalt sample to be observed into a constant temperature oven, set the temperature of the oven at 130°C, and heat until the asphalt completely melts and becomes a flowing liquid;

[0041] (2) Put a clean metal sample dish (inner diameter 10 mm, height 2 mm) into an oven at the same temperature and preheat it for 30 minutes to prevent air bubbles from being generated when the asphalt sample is poured into the mold;

[0042] (3) Take out the metal sample container and place it on the horizontal platform, quickly take out the asphalt sample and stir evenly, take about 0.2g of asphalt with a small spoon, and immediately pour it into the sample container at one time, the height is slightly lower than the sample container edge, such as figure 1 and figure 2 As shown, cover the corresponding cap to prevent contamination of the sample surface;

[0043] (4) Cool the sample dish at room temperature for at least 24 hours to ensure that the annealin...

Embodiment 2

[0047] (1) Put the SBS modified asphalt sample to be observed into a constant temperature oven, set the temperature of the oven at 150°C, and heat the asphalt to a flowing liquid state;

[0048] (2) Put a clean metal sample dish (inner diameter 10 mm, height 2 mm) into an oven at the same temperature and preheat it for 30 minutes to prevent air bubbles from being generated when the asphalt sample is poured into the mold;

[0049] (3) Take out the metal sample container and put it on the horizontal platform, quickly take out the asphalt sample and stir evenly, take about 0.2g of asphalt with a small spoon and inject it into the sample container at one time, the height is slightly lower than the edge of the sample container , cover the corresponding cap to prevent contamination of the sample surface;

[0050] (4) Cool the sample dish at room temperature for at least 24 hours to ensure that the annealing process is completed and the microscopic morphology of the asphalt returns t...

Embodiment 3

[0054] A kind of sample holding dish that the method described in embodiment 1 and 2 is used, as figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of a dish body in a sample holding dish according to an embodiment of the present invention; figure 2 It is a schematic structural view of the cap in the sample container of the embodiment of the present invention; it includes a dish body 1 and a matching cap 2 with the dish body 1, and the cap 2 is covered on the dish body 1, wherein: the dish body 1 and the cap 2 are both Made of metal, the metal is stainless steel 304; the shape of the dish body 1 is a cylinder shape, including the bottom surface and the side; the shape of the cap 2 is a cylinder shape, including the upper bottom surface, the side surface and the upper center of the upper bottom surface. The cap handle 3; the diameter of the bottom surface of the dish body 1 is 10mm, and the height of the side is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap