Post-treatment method for removing photoresist and manufacturing method of semiconductor device

A production method and photoresist technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that wet cleaning is difficult to meet the requirements of the surface cleanliness of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

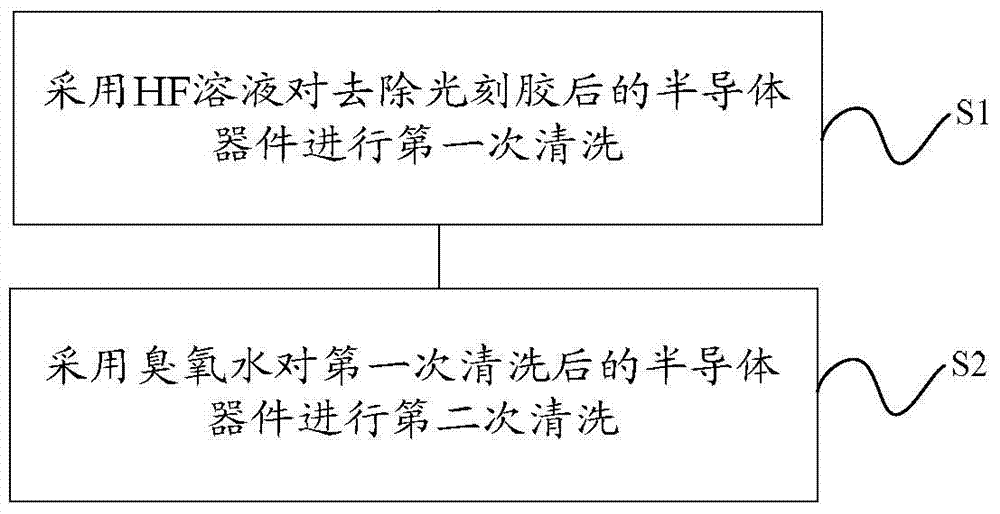

[0037] This embodiment provides a post-processing method for photoresist removal, comprising the following steps:

[0038] The semiconductor device after removing the photoresist is cleaned for the first time, and its specific steps include: at 20 ° C, HF and H 2 The HF solution with the volume ratio of O of 1:500 is sprayed onto the semiconductor device after the first cleaning, and the HF solution is evenly distributed on the surface of the semiconductor device by rotating at a low speed (300rpm), and the flow rate of the HF solution is 1.2L / min; The semiconductor device after removing the photoresist is cleaned for the first time, and the cleaning time is 60 seconds.

[0039] Carry out the second cleaning to the semiconductor device after cleaning for the first time, its specific steps include: at 20 ℃, the O 3 The ozone water with a content of 10ppm is sprayed onto the semiconductor device after the first cleaning, and the ozone water is evenly distributed on the surface ...

Embodiment 2

[0042] This embodiment provides a post-processing method for photoresist removal, comprising the following steps:

[0043] The semiconductor device after removing the photoresist is cleaned for the first time, including the following steps: at 30 ° C, HF and H 2 The HF solution with a volume ratio of O of 1:1600 is placed in a cleaning tank, and then the semiconductor device after removing the photoresist is immersed in the HF solution for cleaning, and the cleaning time is 45 seconds.

[0044] Carry out the second cleaning to the semiconductor device after the first cleaning, its specific steps include: at 30 ℃, the O 3 The ozone water with a content of 55ppm is sprayed on the semiconductor device after the first cleaning, and the ozone water is evenly distributed on the surface of the semiconductor device by rotating at a low speed (300rpm). The flow rate of the ozone water is 1.2L / min; for the first The second cleaning is performed on the semiconductor device after the fir...

Embodiment 3

[0047] This embodiment provides a post-processing method for photoresist removal, comprising the following steps:

[0048] The semiconductor device after removing the photoresist is cleaned for the first time, and its specific steps include: at room temperature, HF and H 2 The HF solution with a volume ratio of O of 1:3000 is sprayed on the semiconductor device after the first cleaning, and the HF solution is evenly distributed on the surface of the semiconductor device by rotating at a low speed (500rpm), and the flow rate of HF is 2L / min; The semiconductor device after removing the photoresist is cleaned for the first time, and the cleaning time is 5 seconds.

[0049] Carry out the second cleaning to the semiconductor device after cleaning for the first time, its specific steps include: at room temperature, the O 3 The ozone water with a content of 100ppm is sprayed on the semiconductor device after the first cleaning, and the ozone water is evenly distributed on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com