Steam retort for nicotine extraction

A technology of steam distillation and water vapor, applied in solid solvent extraction, organic chemistry, etc., can solve problems such as waste of energy, diluting, and poor economic benefits, and achieve the effect of saving energy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific embodiments.

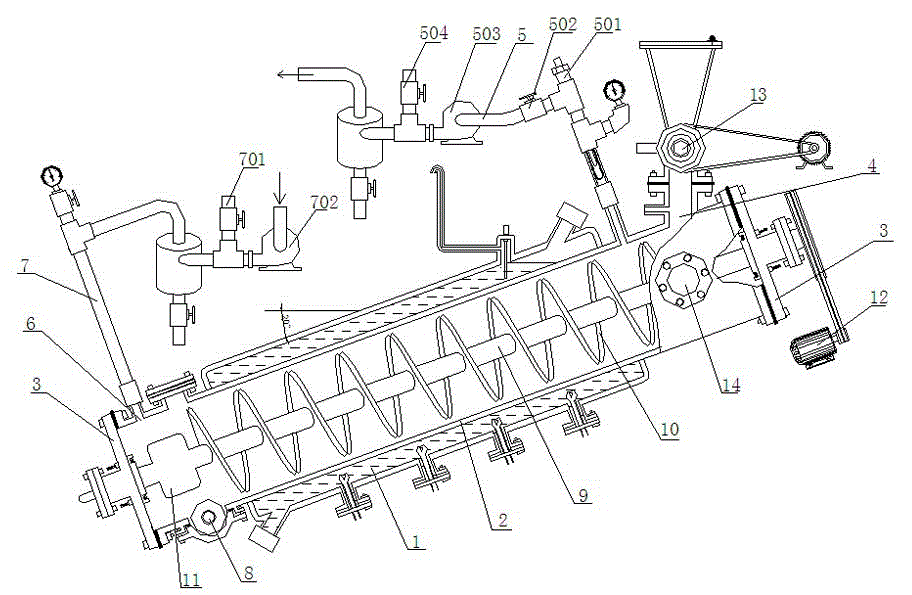

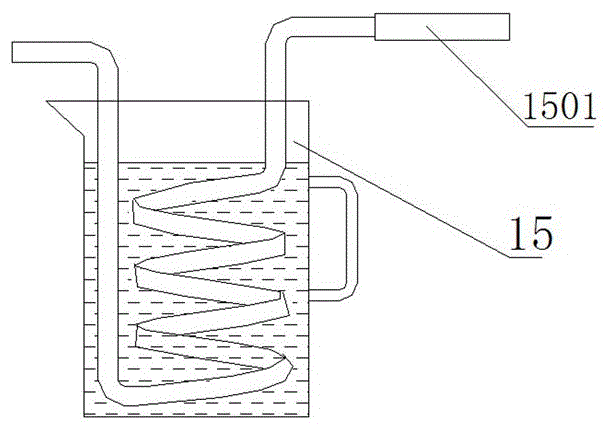

[0018] As shown in the figure: the steam distillation tank used for nicotine extraction includes a cylindrical barrel 2 with a heating jacket 1 and is arranged obliquely. Both ends of the cylindrical barrel 2 are sealed by a shaft sealing cover 3. The higher end of the cylindrical barrel 2 is the feed end, and the top of the feed end is provided with a feed port 4, and the cylindrical barrel 2 is provided with a steam discharge pipe 5 connected with the acid absorption device near the feed port 4. 2 The lower end is the discharge end, the top and bottom of the discharge end are respectively provided with an air inlet 6 and a discharge port, the air inlet 6 is connected to the water vapor introduction pipe 7, and the discharge port is connected to the residue solid-liquid separation devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com