Trimming die capable of being quickly clamped

A trimming die, fast technology, applied to fast clamping trimming die. It can solve problems such as the inability to realize production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

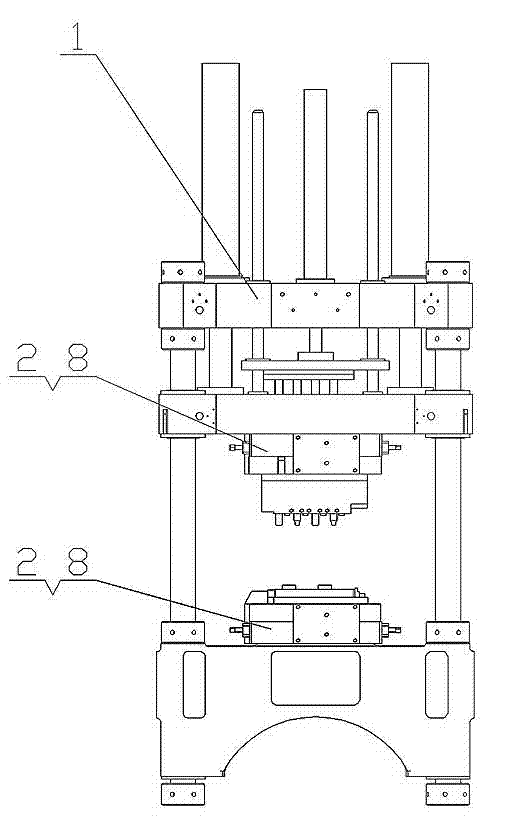

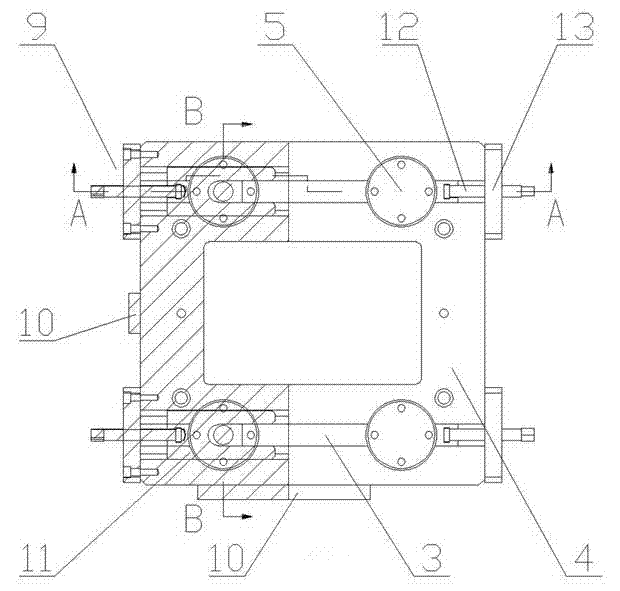

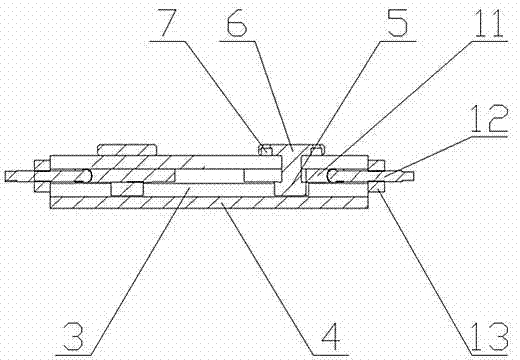

[0016] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 6 Shown: a quick clamping and trimming die, including a trimming machine 1, on the upper and lower mold bases of the trimming machine 1, a mold quick clamping device 2 is respectively arranged, which can realize the quick connection of the mold and the mold base. exist figure 1 What is drawn in the middle is the trimming machine 1 that has been connected with the trimming die 8, and the mold quick clamping device 1 is positioned at the trimming die 8, in figure 1 It is not shown in the figure; the mold quick clamping device 2 includes a template 4, and two T-shaped slots 3 are opened horizontally and parallelly on the template 4, and four locking blocks 5 are arranged to match the T-shaped slots 3. Four counterbores 7 are opened on the disc-shaped end 6 of the block 5, and these counterbores 7 are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com