Multi-slide loading capacity and pneumatic atomization liquid spraying dyeing machine

A technology of pneumatic atomization and loading capacity, which is used in measurement devices, preparation and sampling of samples for testing, etc., which can solve the problems of insufficient droplets, easy to touch holes, and a small number of glass slides, so as to reduce the manufacturing cost. and running costs, increasing the number of loads, and good dyeing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

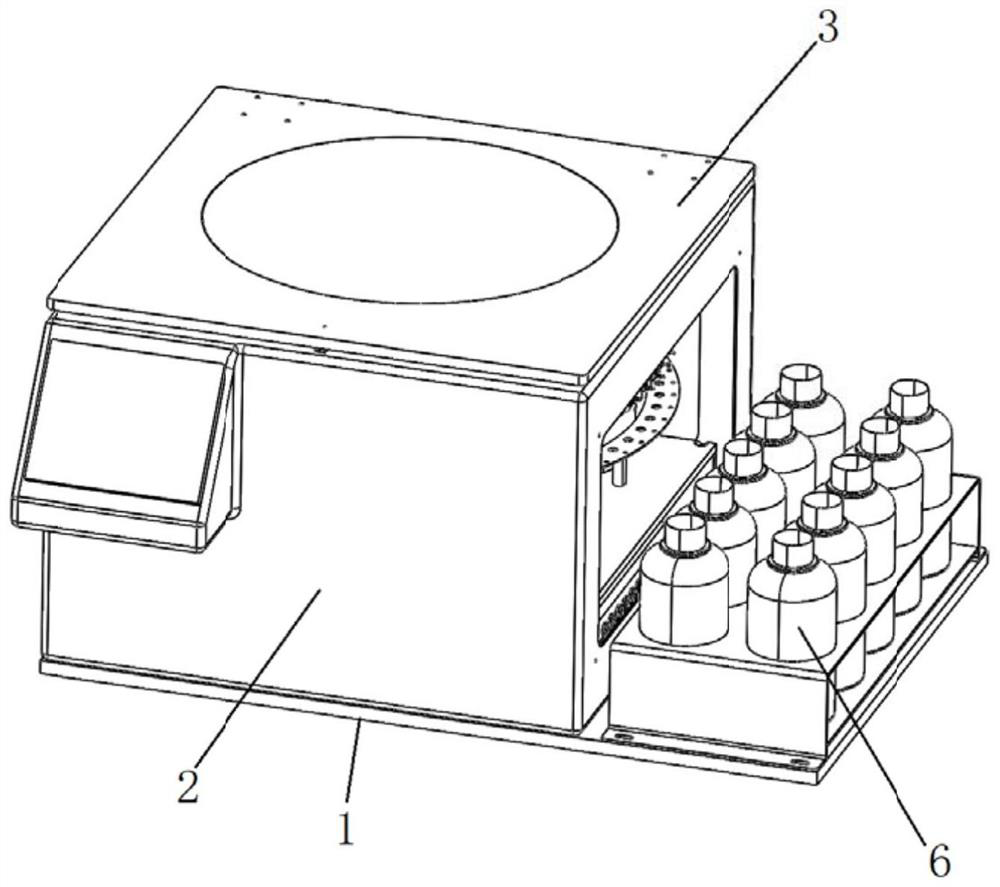

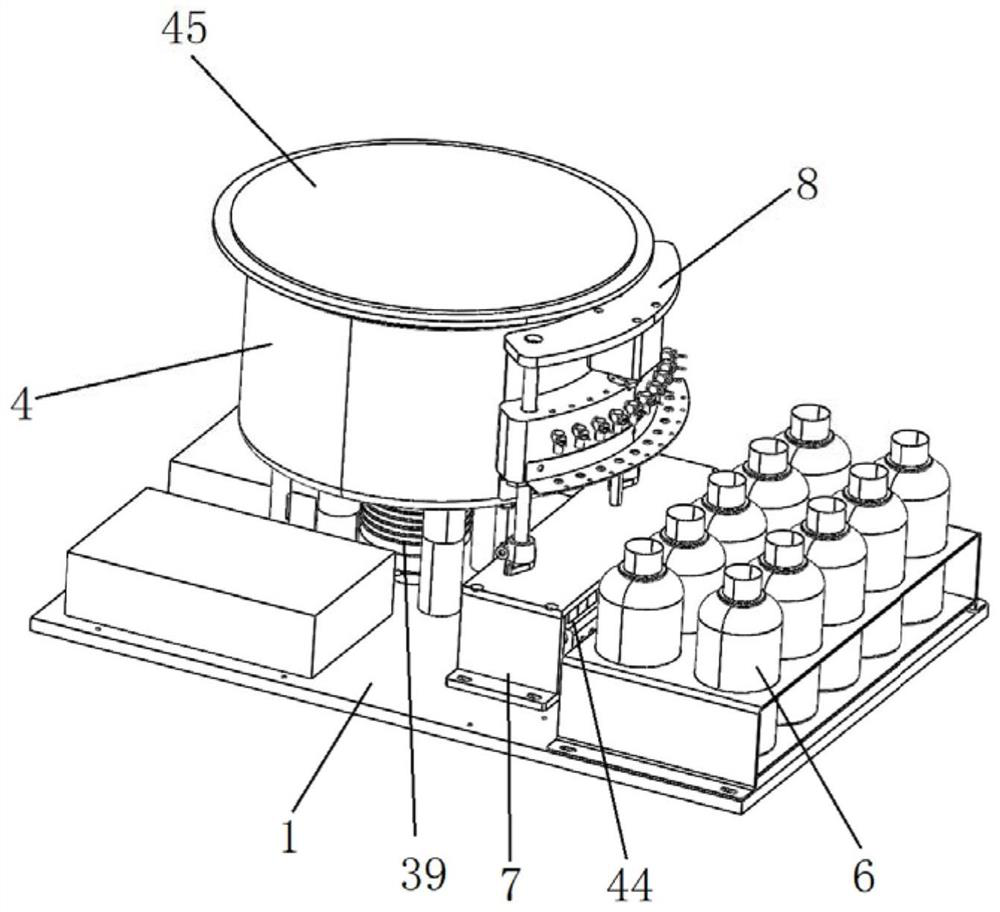

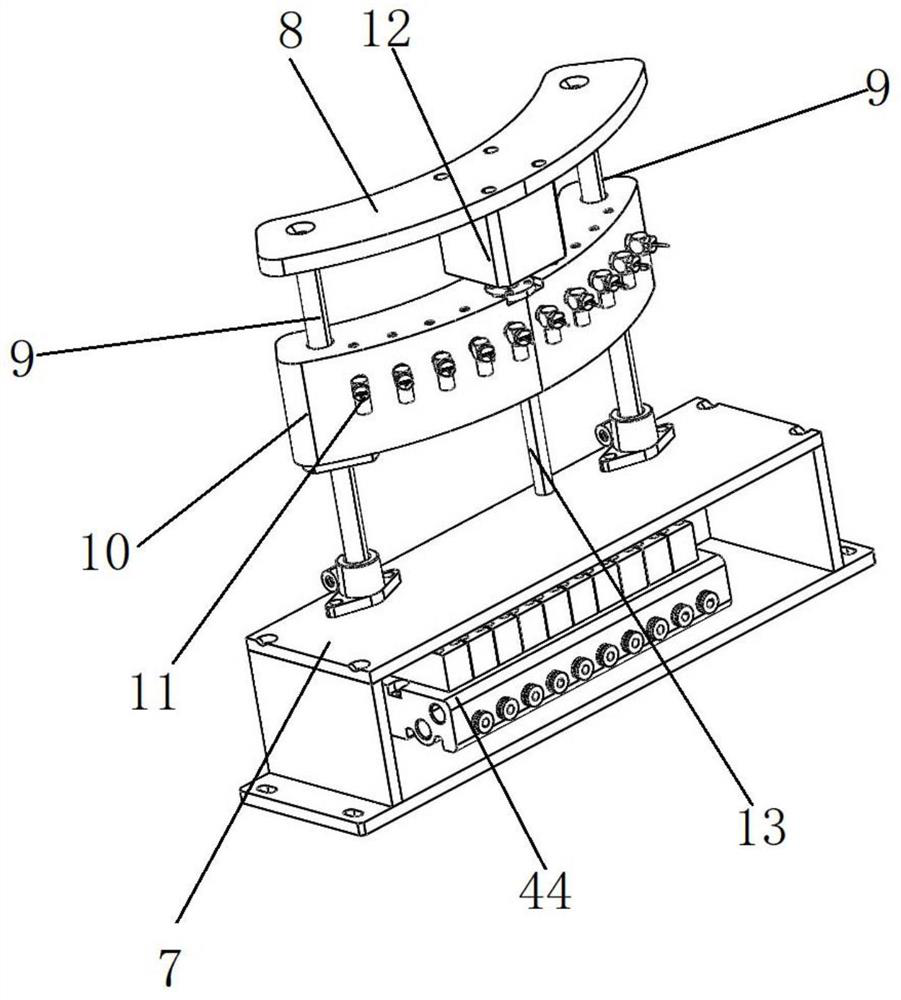

[0059] refer to figure 1 , figure 2 and Figure 4 As shown, this embodiment discloses a dyeing machine with a multi-slide loading capacity and pneumatic atomization and liquid spraying. The cover 2 is provided with a staining pot 4, and the shield 2 is also provided with a rotary driving device positioned below the staining pot 4. The staining pot 4 is provided with a slide tray, and the rotary drive device and the slide tray in the staining pot 4 The detachable connection, the rotary drive device is used to drive the slide tray to rotate in the dyeing pot 4, the protective cover 2 is also equipped with a pneumatic atomization spray mechanism, the side wall of the protective cover 2 is provided with a spray port 5, and the pneumatic atomization spray T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com