External pressure type hollow fiber curtain type membrane and preparation method thereof

An external pressure type, curtain membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane fouling, inability to ensure uniform spacing, and low filling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

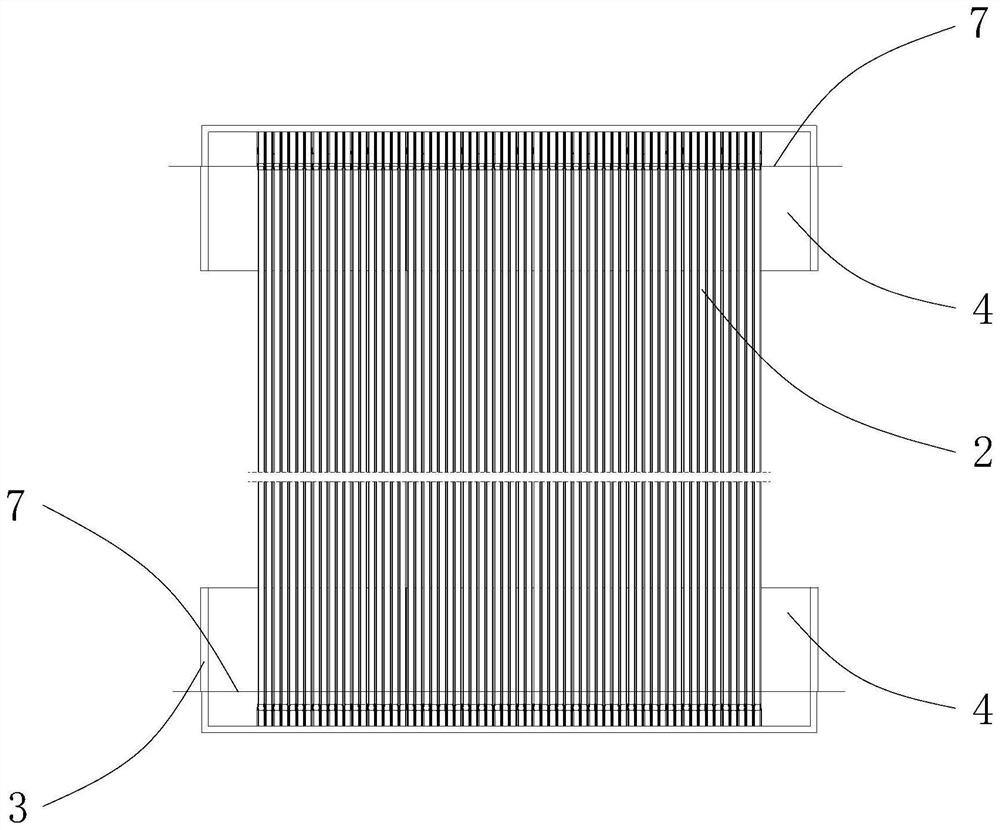

[0033] The technical solutions of the present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0034] see Figure 1-4 As shown, this embodiment provides a method for preparing an external pressure hollow fiber curtain membrane, comprising the following steps:

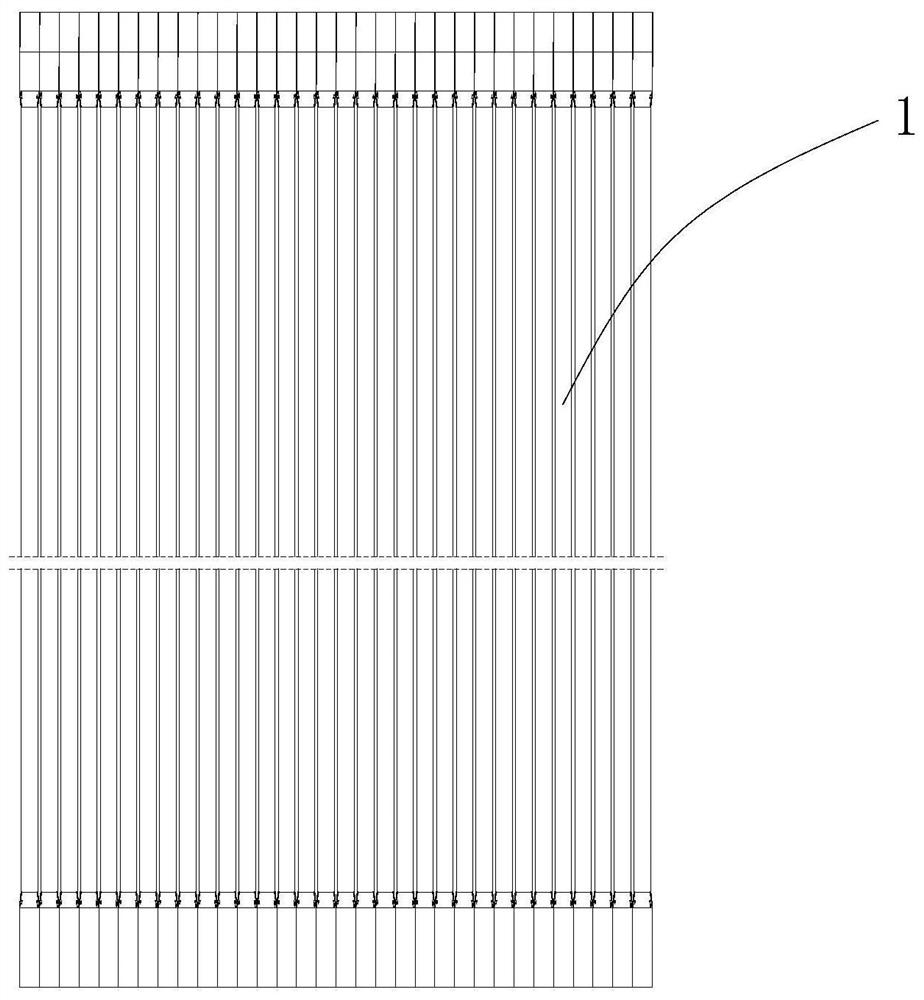

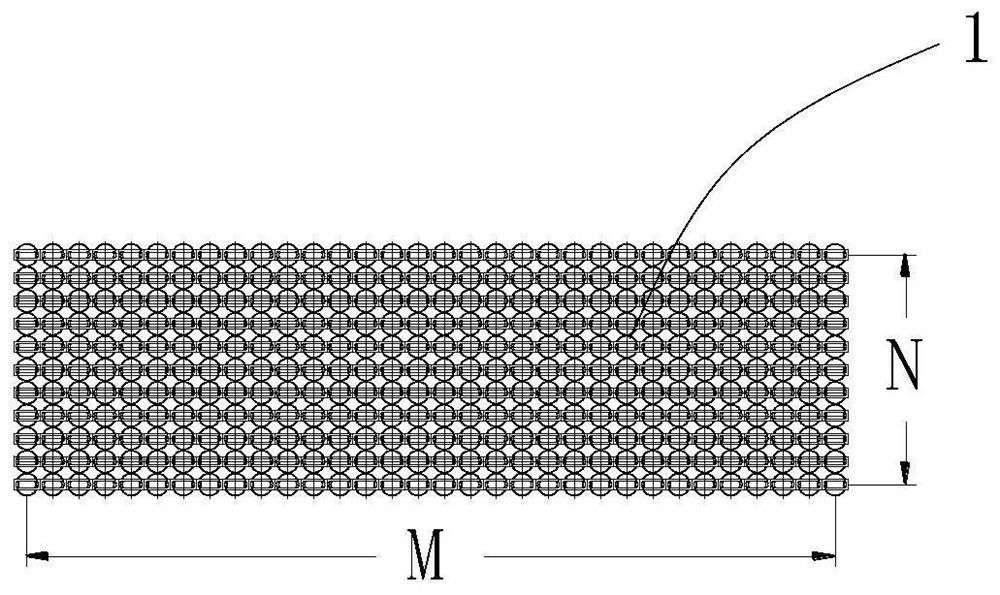

[0035] (1) Spread M parallel wet film filaments 1 on the same plane, so that the wet film filaments 1 are arranged equidistantly and both ends are aligned respectively, see figure 1 As shown, that is, the upper ends of the M wet film filaments 1 are aligned with each other, and the lower ends are also aligned with each other;

[0036] Fix and connect the two ends of M wet film filaments 1 respectively by wire braiding or welding to make a membrane row; fix and connect the ends of wet film filaments 1 by wire braiding or welding, and simultaneously 1 is sealed at the end, which can prevent the adhesive from entering the membrane filament and causing polluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com