Mold and system for filling foaming material into refrigerator body

A foaming material and mold technology, applied in the field of refrigerator box foaming, can solve problems such as low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

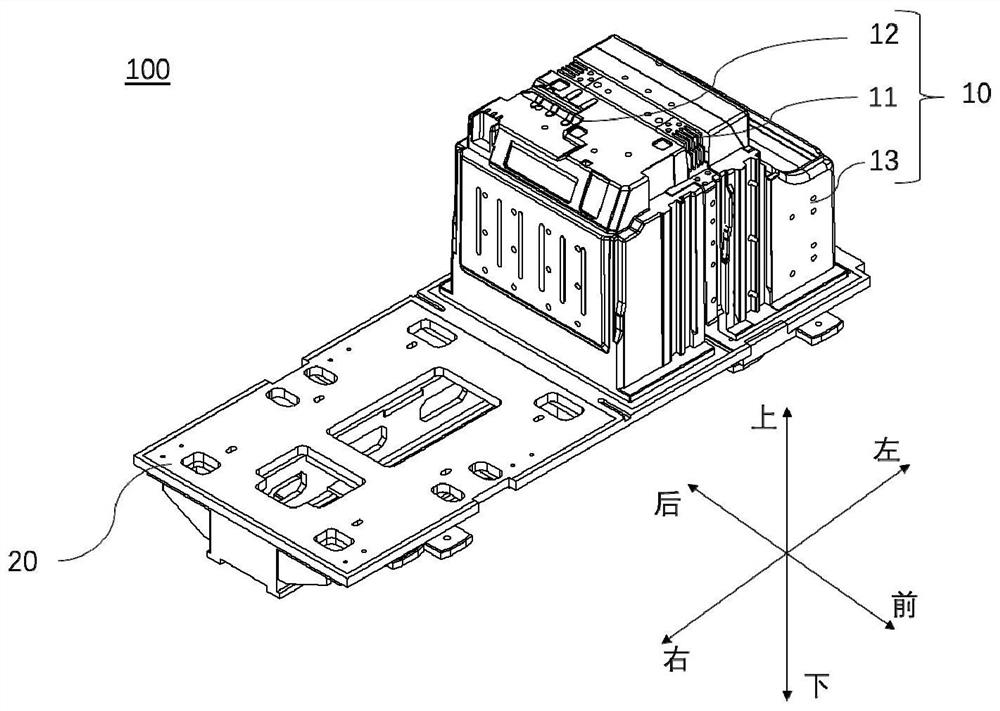

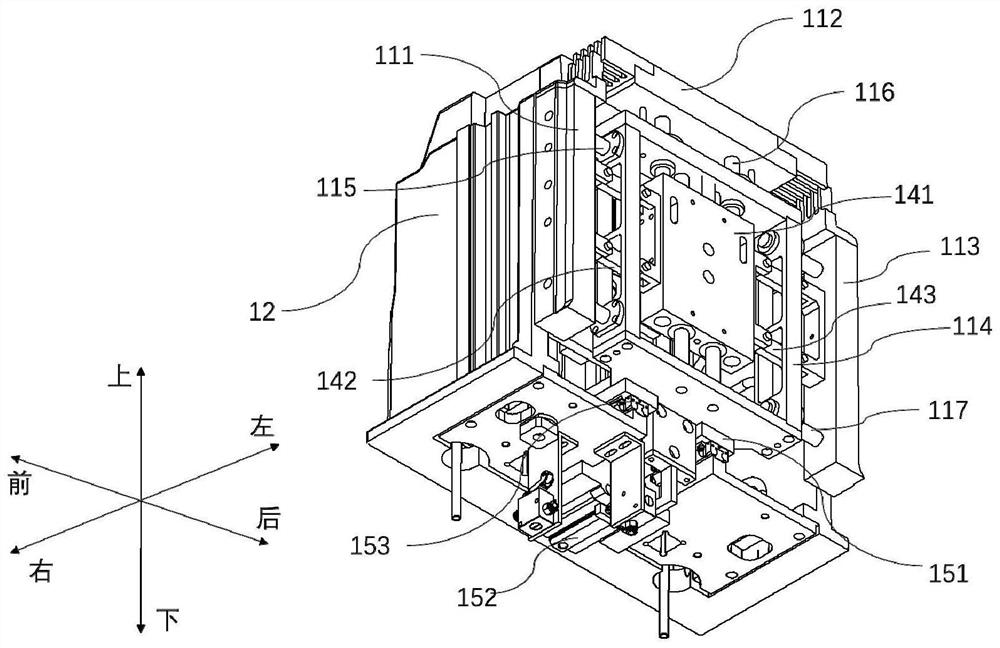

[0022] The present invention will be further described below in conjunction with accompanying drawing. Such as figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a mold 100, which is used to prevent the deformation of the refrigerator cabinet when the foaming machine fills the foam material into it. The refrigerator cabinet includes a double-layer cabinet with a refrigerating chamber and a suspended beam arranged in the refrigerating chamber and connected to the inner wall of the double-layer cabinet. The mold 100 includes a mold base 20 and a mold core 10 arranged on the mold base 20. The mold core 10 includes a left module 13, a right module 12 and an expansion-contraction module 11, and can drive the expansion-contraction module 11 between the left module 13 and the right module 12. Between the first driving mechanism 14 that expands and contracts and the second driving mechanism 15 that can drive the expanded and contracted modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com