Anti-wear and deterioration additive for enhancing wear-resisting strength of grinding ball and using method

A wear-resistant strength and additive technology, applied in the field of casting grinding ball additives, can solve problems such as poor utilization effect and oxidation, and achieve the effects of improving comprehensive hardness and wear resistance, improving wear resistance, and stable and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

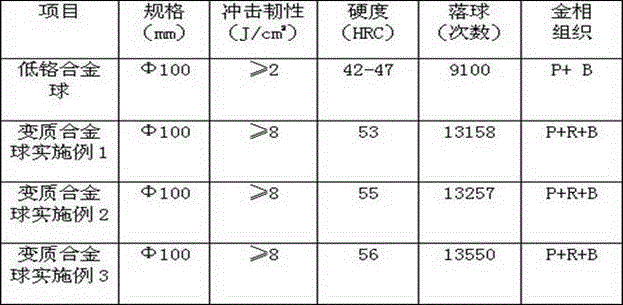

Examples

Embodiment 1

[0021] Before smelting, the two groups A and B are prepared according to 0.8% and 0.2% of the weight of molten iron respectively; the compound of group A is aluminum powder accounting for 20%, silicon calcium barium accounting for 20% 、 Titanium carbide accounts for 40%, rare earth ferrosilicon alloy accounts for 20%, and the B group compound is boron iron 0.5%, rare earth CeO 2 50%, the rest is calcium oxide.

[0022] In order to improve the use efficiency of additives, the present invention puts group B in the baked ladle before it is released from the furnace; in the later stage of smelting, when the chemical composition of the molten iron reaches the following indicators C: 2.2-3.0 Si: 0.7-1.4 Cr: 1.6-2.5 Mn: 1.0~1.6 After P, S<0.05; Three minutes before the molten iron is discharged, remove the impurities on the surface of the molten iron, then add the prepared group A into the furnace, and power on for 3 minutes to reach the temperature of the molten iron. Generally, the...

Embodiment 2

[0028] Before smelting, two groups of A and B were prepared according to 2% and 1% of the weight of molten iron respectively; the compound of group A was aluminum powder accounting for 20% and silicon calcium barium accounting for 10% 、 Titanium carbide accounts for 50%, rare earth ferrosilicon alloy accounts for 20%, and the described B group compound is boron iron 1%, rare earth CeO 2 60%, the rest is calcium oxide.

[0029] In order to improve the use efficiency of additives, the present invention puts group B in the baked ladle before it is released from the furnace; in the later stage of smelting, when the chemical composition of the molten iron reaches the following indicators C: 2.2-3.0 Si: 0.7-1.4 Cr: 1.6-2.5 Mn: 1.0~1.6 After P, S<0.05; 3 minutes before the molten iron is discharged, remove the impurities on the surface of the molten iron, add the prepared group A into the furnace, and power on for 3 minutes to reach the temperature of the molten iron. Generally, the ...

Embodiment 3

[0035] Before smelting, the A and B groups are prepared according to 1.5% and 0.5% of the weight of molten iron respectively; the A group of compounds is aluminum powder accounting for 25%, silicon calcium barium accounting for 15% 、 Titanium carbide accounts for 45%, rare earth ferrosilicon alloy accounts for 15%, and the B group compound is boron iron 0.8%, rare earth CeO 2 55%, the rest is calcium oxide.

[0036] In order to improve the use efficiency of additives, the present invention puts group B in the baked ladle before it is released from the furnace; in the later stage of smelting, when the chemical composition of the molten iron reaches the following indicators C: 2.2-3.0 Si: 0.7-1.4 Cr: 1.6-2.5 Mn: 1.0~1.6 After P, S<0.05; 3 minutes before the molten iron is discharged, remove the impurities on the surface of the molten iron, add the prepared group A into the furnace, and power on for 3 minutes to reach the temperature of the molten iron. Generally, the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com