Novel blade padlock cover

A blade and stuffing cover technology is applied in the field of padlock stuffing cover, which can solve the problems of increasing manufacturing cost, complicated process, unreasonable structure, etc., and achieve the effects of reducing production cost, improving production efficiency and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

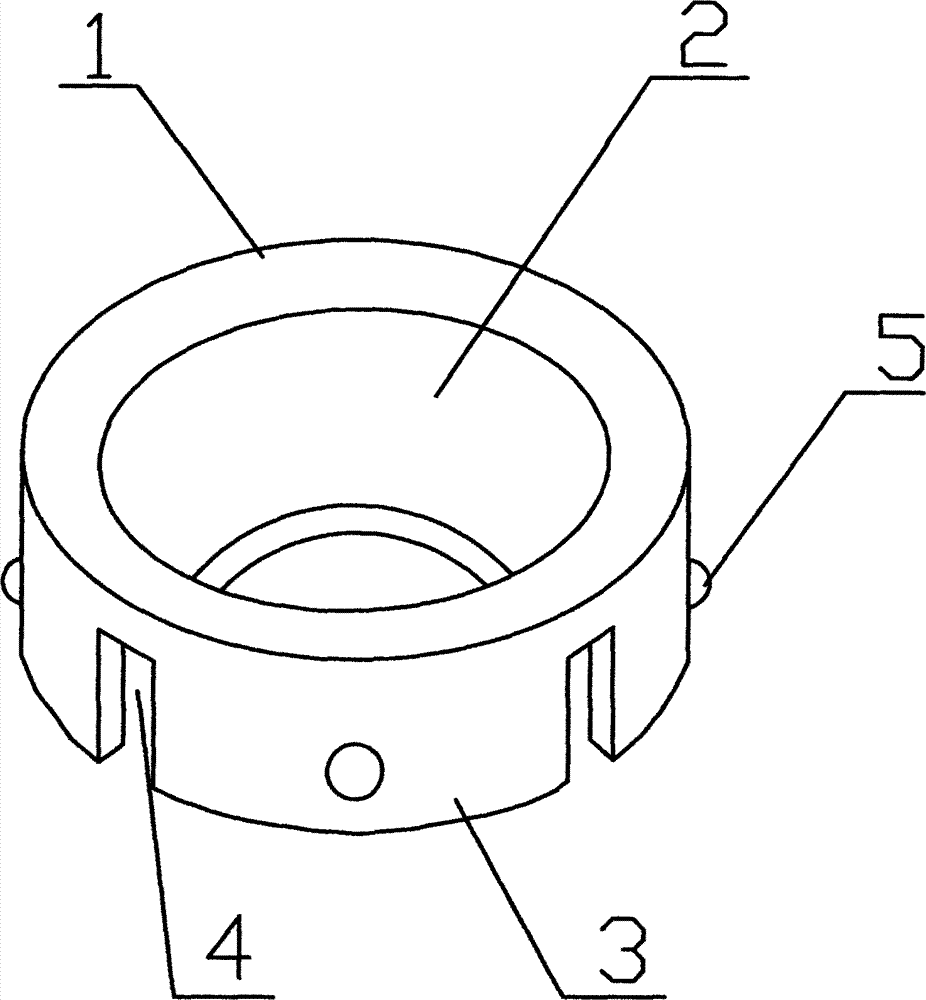

[0010] A new type of blade padlock cover, comprising a cover body 1 formed by stamping and stretching a metal plate of 0.2 mm to 2.0 mm, the cover body 1 is provided with a key hole 2, and the diameter of the key hole 2 gradually increases from outside to inside. Reduced, 2~8 empennage blades 3 are arranged on the inside of the stuffy cover body 1, and buffer slots 4 with a width of 1mm~3mm are provided between the empennage blades 3; At least one barb 5 is provided on the outer surface; the section of the closure body 1 is circular.

[0011] The end of the key hole 2 with the large opening facing outwards, insert the tail blade 3 into the blade padlock lock body, the barb 5 is consistent with the snap ring groove inside the blade padlock lock body, and is stuck with it, and the head of the cover body 1 Flat with the bottom of the blade padlock lock body, the installation of the present invention has just been completed. After using the present invention, the time for install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com