Hydraulic drilling rig primary filter linkage slag discharge device

A hydraulic drilling rig and coarse filter technology, which is used in earth-moving drilling, wellbore/well components, slitting machinery, etc., can solve the problem of high dust accumulation, and achieve the effect of solving the problem of excessive dust accumulation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

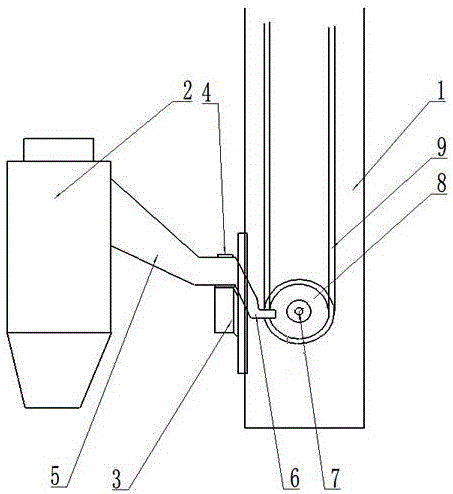

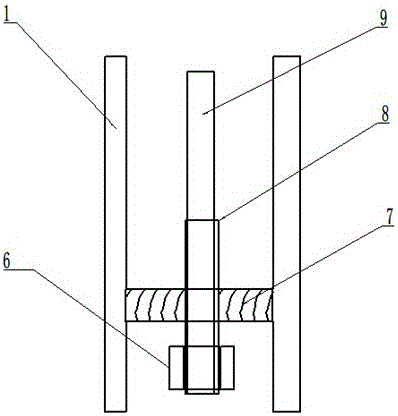

[0008] The present invention will now be further described in detail with reference to the accompanying drawings.

[0009] like figure 1 , 2 As shown, the chain guide wheel shaft 7 is installed on the propelling beam 1 and is rigidly connected with the propelling beam 1; the chain guide wheel 8 is installed on the chain guide wheel shaft 7, and the chain 9 is engaged with the chain guide wheel 8; The thread meshes with the thread on the inner side of the chain guide wheel 8; the coarse filter 2 is connected with the coarse filter swing arm 5, and the coarse filter swing arm 5 is installed on the coarse filter shaft seat 3 through the swing arm pin 4, and the coarse filter shaft seat 3 is installed on the propulsion On the beam 1, a shift fork 6 is installed at the end of the strainer swing arm 5, and the shift fork 6 is in contact with the chain guide wheel 8.

[0010] During operation, the chain 9 rotates, so that the chain guide wheel 8 moves along the thread direction, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap