A method for online monitoring of lubricating oil in wind power transmission

A transmission and lubricating oil technology, which is applied in the field of online monitoring of mechanical systems, can solve the problems of failure to give the degree of lubricant performance decay and wear mechanism, and achieve the effects of avoiding secondary rolling, reducing flow rate pulsation, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

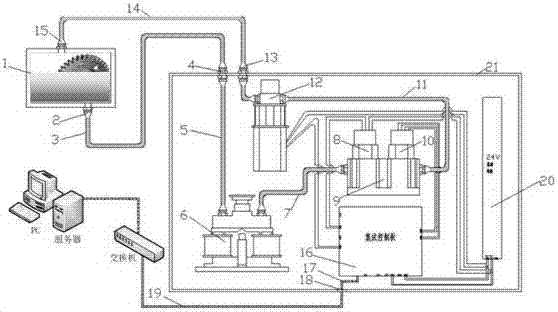

[0052] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

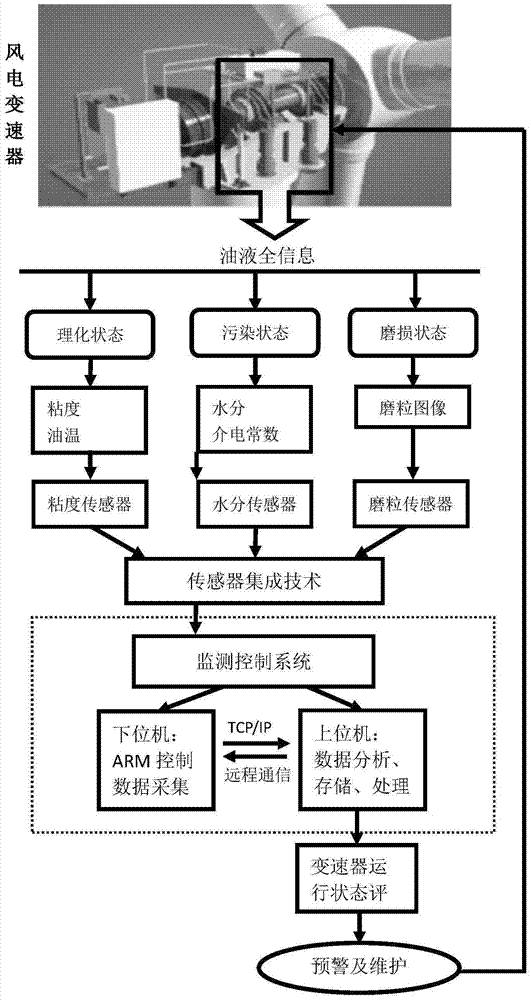

[0053] refer to figure 1 , an online monitoring method for lubricating oil of a wind power transmission, comprising the following steps:

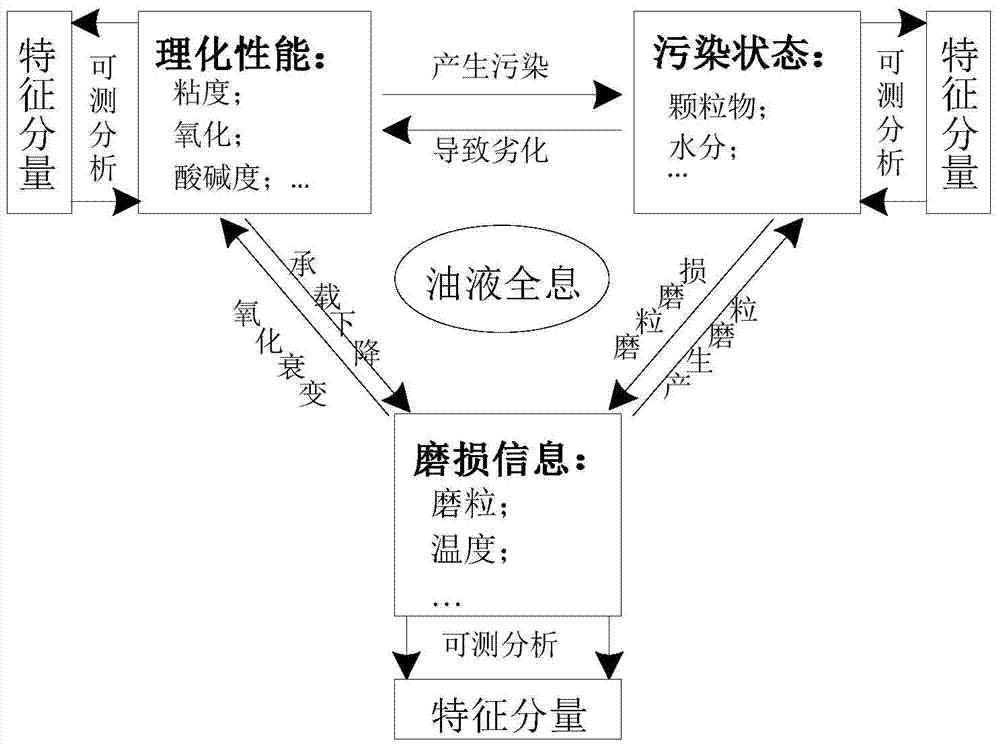

[0054] Step 1. Through coupling analysis, establish a tribological state characterization system for wind power transmission based on three types of information: physical and chemical, pollution and wear, and provide a coupling reasoning mechanism; refer to figure 2 , establish an integrated information monitoring system through measurability analysis, and use viscosity, moisture and abrasive particles as the measurable features corresponding to the above three types of information;

[0055] Step 2: Perform feature extraction through the collected wear particle image to obtain the deposited wear particle concentration index IPCA in the oil, and the specific steps are:

[0056] S1, take out the image in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com